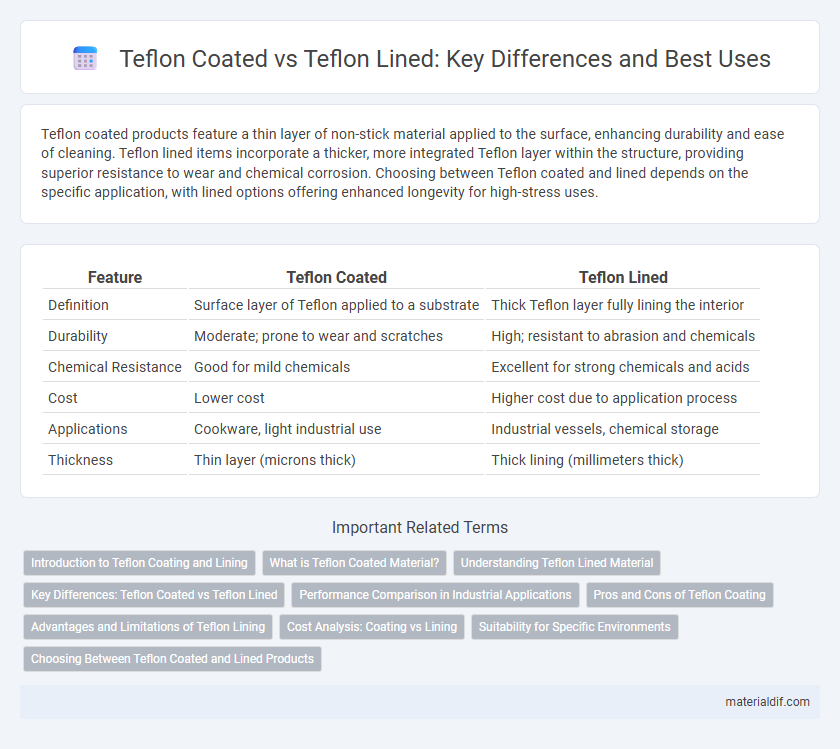

Teflon coated products feature a thin layer of non-stick material applied to the surface, enhancing durability and ease of cleaning. Teflon lined items incorporate a thicker, more integrated Teflon layer within the structure, providing superior resistance to wear and chemical corrosion. Choosing between Teflon coated and lined depends on the specific application, with lined options offering enhanced longevity for high-stress uses.

Table of Comparison

| Feature | Teflon Coated | Teflon Lined |

|---|---|---|

| Definition | Surface layer of Teflon applied to a substrate | Thick Teflon layer fully lining the interior |

| Durability | Moderate; prone to wear and scratches | High; resistant to abrasion and chemicals |

| Chemical Resistance | Good for mild chemicals | Excellent for strong chemicals and acids |

| Cost | Lower cost | Higher cost due to application process |

| Applications | Cookware, light industrial use | Industrial vessels, chemical storage |

| Thickness | Thin layer (microns thick) | Thick lining (millimeters thick) |

Introduction to Teflon Coating and Lining

Teflon coating involves applying a thin layer of polytetrafluoroethylene (PTFE) to surfaces, providing non-stick, corrosion-resistant, and heat-tolerant properties widely used in cookware and industrial applications. Teflon lining refers to a thick, molded layer of PTFE inside tanks or pipes designed for chemical resistance and durability in harsh environments. Understanding the difference between Teflon coated and Teflon lined surfaces is essential for selecting the right solution based on wear conditions, chemical exposure, and maintenance requirements.

What is Teflon Coated Material?

Teflon coated material refers to a substrate, often metal, that has been sprayed or dipped with a thin layer of polytetrafluoroethylene (PTFE) to create a non-stick, heat-resistant surface. This coating enhances durability and corrosion resistance while maintaining the base material's strength and shape. Commonly used in cookware and industrial applications, Teflon coated surfaces reduce friction and prevent material buildup.

Understanding Teflon Lined Material

Teflon lined materials feature a durable layer of PTFE bonded internally to metal surfaces, offering superior chemical resistance and non-reactive properties essential for industrial applications. Unlike Teflon coated products, which apply a thin, external PTFE film, Teflon lining ensures consistent protection against corrosion, abrasion, and high temperatures within pipes, tanks, and vessels. This lining prevents contamination and extends equipment lifespan, making it the preferred choice in chemical processing, pharmaceuticals, and food manufacturing industries.

Key Differences: Teflon Coated vs Teflon Lined

Teflon coated surfaces feature a thin, non-stick polymer layer applied to the exterior of cookware or equipment, providing easy food release and resistance to corrosion and chemicals. Teflon lined products have a thicker, bonded PTFE layer built into the interior walls, enhancing durability and offering superior protection against abrasion and chemical attack for industrial applications. The key difference lies in coating's surface-level application versus lining's integrated, more robust construction designed for heavy-duty use.

Performance Comparison in Industrial Applications

Teflon coated surfaces provide enhanced non-stick and chemical resistance properties, ideal for reducing friction and preventing material buildup in industrial processing equipment. Teflon lined components offer superior durability and a thicker protective barrier, making them better suited for high-wear applications involving abrasive or corrosive substances. Performance comparison indicates Teflon lining excels in long-term abrasion resistance, while Teflon coating is optimal for applications requiring precise, smooth finishes with minimal interference.

Pros and Cons of Teflon Coating

Teflon coated surfaces offer excellent non-stick properties and resistance to high temperatures, making them ideal for cookware and industrial applications. However, the coating can wear off over time, leading to reduced durability and potential exposure of the underlying material. Unlike Teflon lining, which is typically thicker and more durable, Teflon coating provides a thinner protective layer that may require more frequent maintenance or replacement.

Advantages and Limitations of Teflon Lining

Teflon lining provides superior chemical resistance and non-stick properties, making it ideal for handling corrosive substances in industrial applications. It offers high-temperature tolerance up to 260degC and excellent electrical insulation but is limited by its susceptibility to mechanical damage and abrasion. Compared to Teflon coating, Teflon lining delivers enhanced durability and uniform protection, albeit with increased installation complexity and cost.

Cost Analysis: Coating vs Lining

Teflon coated products generally have a lower initial cost compared to Teflon lined alternatives due to simpler application processes and less material usage. Teflon lining provides superior chemical resistance and durability, which can reduce long-term maintenance and replacement expenses despite higher upfront investment. Evaluating total cost of ownership reveals that Teflon lining may be more cost-effective for aggressive chemical environments, whereas Teflon coating suits applications with less exposure and tighter budget constraints.

Suitability for Specific Environments

Teflon coated surfaces offer excellent non-stick properties ideal for cookware exposed to frequent high-temperature cooking and easy cleaning requirements in household kitchens. Teflon lined equipment, on the other hand, provides superior chemical resistance and is more suitable for industrial applications involving corrosive substances or harsh chemical environments. Choosing between Teflon coated and lined depends heavily on the specific environmental demands, such as temperature range, chemical exposure, and mechanical wear.

Choosing Between Teflon Coated and Lined Products

Teflon coated products feature a thin, non-stick polymer layer applied to surfaces, offering excellent release properties and ease of cleaning, ideal for cookware and industrial molds. Teflon lined products consist of a solid substrate encased with a thicker layer of Teflon, providing superior chemical resistance and durability essential for tanks, pipes, and chemical processing equipment. Selecting between Teflon coated and lined depends on application requirements such as exposure to abrasive materials, chemical compatibility, and longevity in demanding environments.

Teflon Coated vs Teflon Lined Infographic

materialdif.com

materialdif.com