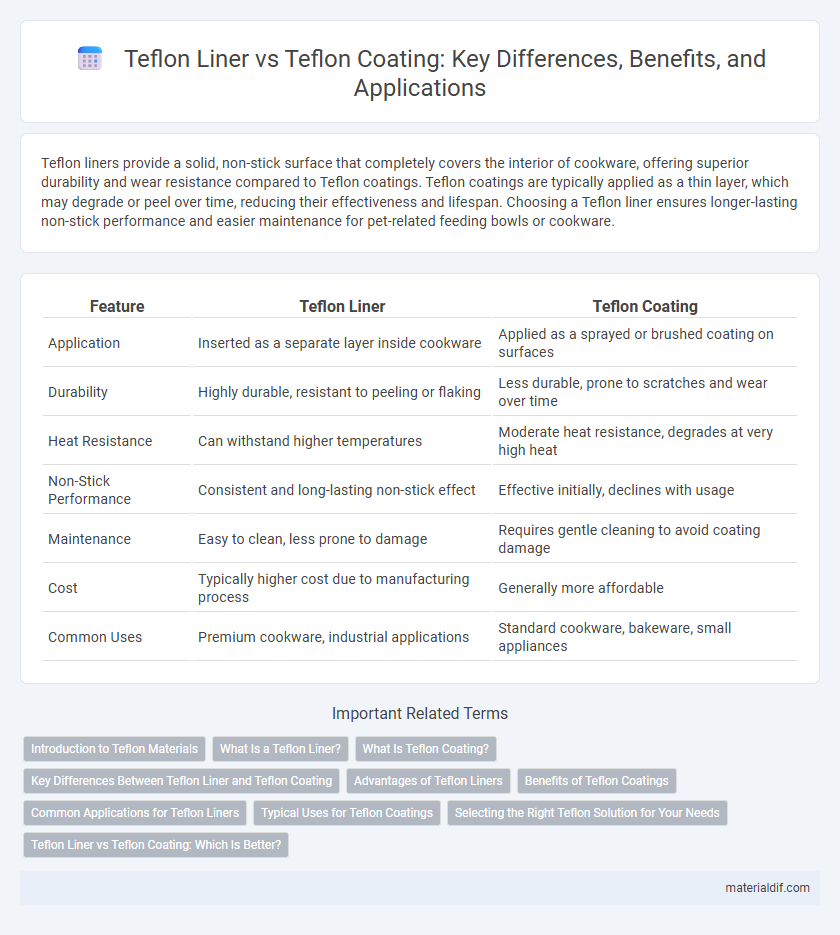

Teflon liners provide a solid, non-stick surface that completely covers the interior of cookware, offering superior durability and wear resistance compared to Teflon coatings. Teflon coatings are typically applied as a thin layer, which may degrade or peel over time, reducing their effectiveness and lifespan. Choosing a Teflon liner ensures longer-lasting non-stick performance and easier maintenance for pet-related feeding bowls or cookware.

Table of Comparison

| Feature | Teflon Liner | Teflon Coating |

|---|---|---|

| Application | Inserted as a separate layer inside cookware | Applied as a sprayed or brushed coating on surfaces |

| Durability | Highly durable, resistant to peeling or flaking | Less durable, prone to scratches and wear over time |

| Heat Resistance | Can withstand higher temperatures | Moderate heat resistance, degrades at very high heat |

| Non-Stick Performance | Consistent and long-lasting non-stick effect | Effective initially, declines with usage |

| Maintenance | Easy to clean, less prone to damage | Requires gentle cleaning to avoid coating damage |

| Cost | Typically higher cost due to manufacturing process | Generally more affordable |

| Common Uses | Premium cookware, industrial applications | Standard cookware, bakeware, small appliances |

Introduction to Teflon Materials

Teflon liner and Teflon coating are both made from polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its non-stick and heat-resistant properties. Teflon liners are typically thick, molded sheets used as a durable barrier in pipes and containers, providing chemical resistance and thermal stability. Teflon coatings, on the other hand, are thin, sprayed or applied layers that enhance surface smoothness and reduce friction in cookware and industrial applications.

What Is a Teflon Liner?

A Teflon liner is a durable, non-stick inner layer commonly used in cookware and industrial containers to prevent food or substances from sticking and to facilitate easy cleaning. Unlike Teflon coatings, which are thin layers applied to surfaces, Teflon liners are typically thicker and molded to fit specifically within pots, pans, or containers. This structural design enhances resistance to scratching and peeling, providing long-lasting non-stick performance and chemical protection.

What Is Teflon Coating?

Teflon coating is a thin layer of polytetrafluoroethylene (PTFE) applied to cookware and industrial equipment surfaces to provide non-stick, heat-resistant, and chemical-resistant properties. Unlike Teflon liners that are solid sheets fitted inside containers, Teflon coatings bond directly to the substrate, ensuring even coverage and durability. This coating reduces friction and prevents material adhesion, enhancing the lifespan and performance of various products.

Key Differences Between Teflon Liner and Teflon Coating

Teflon liner refers to a solid sheet or film of PTFE material used as a protective barrier inside containers or pipes, ensuring chemical resistance and preventing corrosion. Teflon coating involves applying a thin layer of PTFE on surfaces to reduce friction, enhance non-stick properties, and protect against wear. The key difference lies in Teflon liner providing a thicker, more durable layer primarily for protection and containment, while Teflon coating offers a thinner, more flexible surface treatment for low friction and easy cleaning.

Advantages of Teflon Liners

Teflon liners provide superior durability and a uniform non-stick surface that resists peeling and flaking compared to traditional Teflon coatings. These liners enhance heat distribution for consistent cooking performance and offer longer-lasting protection against corrosion and chemical reactions. Their seamless design minimizes food buildup and simplifies cleaning, making them ideal for industrial and high-use cookware applications.

Benefits of Teflon Coatings

Teflon coatings provide a durable, non-stick surface that improves food release and simplifies cleaning compared to traditional Teflon liners. These coatings enhance resistance to high temperatures, chemical corrosion, and wear, extending the lifespan of cookware and industrial equipment. Their even application ensures consistent performance and reduced risk of peeling or flaking seen with some liners.

Common Applications for Teflon Liners

Teflon liners are widely used in chemical processing equipment, providing exceptional resistance to corrosive chemicals and high temperatures, making them ideal for pipes, tanks, and valves. They offer superior non-stick properties and durability in industrial applications such as pharmaceutical manufacturing and food processing. Unlike Teflon coatings, liners provide a thicker, more uniform protective barrier that enhances longevity and performance in harsh environments.

Typical Uses for Teflon Coatings

Teflon coatings are widely used in cookware to provide a non-stick surface that simplifies cleaning and reduces the need for cooking oils. Industrial applications include conveyor belts, bearings, and gaskets where low friction and chemical resistance are essential. These coatings also protect electrical components and medical devices from corrosion and wear.

Selecting the Right Teflon Solution for Your Needs

Teflon liners offer a durable, non-stick surface ideal for industrial applications requiring long-lasting protection, while Teflon coatings provide a thinner, more flexible layer suited for varied cookware and appliance uses. Selecting the right Teflon solution depends on factors such as surface type, exposure to heat, abrasion resistance, and specific application requirements. Understanding these key differences ensures optimal performance, extending the lifespan of equipment and enhancing usability.

Teflon Liner vs Teflon Coating: Which Is Better?

Teflon liners provide a durable, PTFE-based barrier that completely covers cookware surfaces, preventing food from sticking and ensuring even heat distribution, whereas Teflon coatings are thin layers applied to cookware that can wear off over time, reducing non-stick performance. Choosing between Teflon liner and Teflon coating depends on durability preferences and cooking habits; liners typically offer longer-lasting non-stick properties and superior resistance to scratches and abrasions. For heavy-duty or frequent use, Teflon liners outperform coatings by maintaining non-stick efficiency and chemical resistance, making them the better option for longevity and performance.

Teflon Liner vs Teflon Coating Infographic

materialdif.com

materialdif.com