Teflon tape provides a quick and clean solution for sealing pipe threads, creating a tight barrier that prevents leaks by filling gaps and irregularities. Thread sealant, however, offers a more durable and chemical-resistant seal, adhering to threads and hardening over time to withstand high pressures and temperatures. Choosing between Teflon tape and thread sealant depends on the application requirements, with tape favored for ease of use and thread sealant preferred for long-lasting, heavy-duty seals.

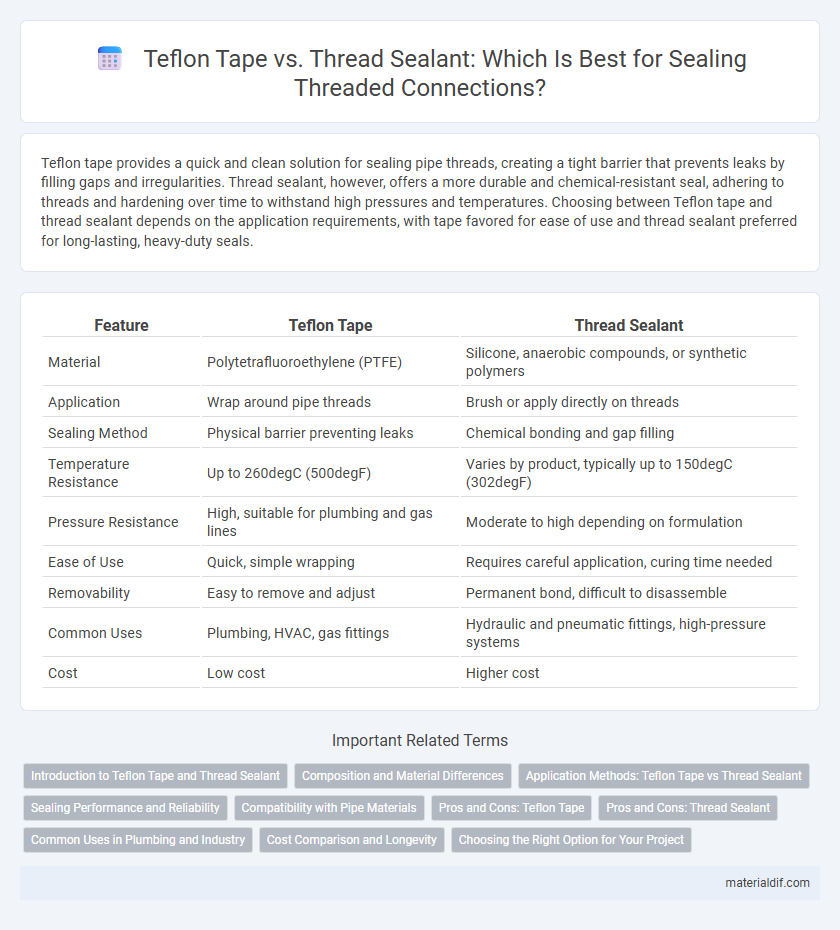

Table of Comparison

| Feature | Teflon Tape | Thread Sealant |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Silicone, anaerobic compounds, or synthetic polymers |

| Application | Wrap around pipe threads | Brush or apply directly on threads |

| Sealing Method | Physical barrier preventing leaks | Chemical bonding and gap filling |

| Temperature Resistance | Up to 260degC (500degF) | Varies by product, typically up to 150degC (302degF) |

| Pressure Resistance | High, suitable for plumbing and gas lines | Moderate to high depending on formulation |

| Ease of Use | Quick, simple wrapping | Requires careful application, curing time needed |

| Removability | Easy to remove and adjust | Permanent bond, difficult to disassemble |

| Common Uses | Plumbing, HVAC, gas fittings | Hydraulic and pneumatic fittings, high-pressure systems |

| Cost | Low cost | Higher cost |

Introduction to Teflon Tape and Thread Sealant

Teflon tape, made from polytetrafluoroethylene (PTFE), is a thin, white film used to seal pipe threads and prevent leakage by filling gaps between threaded connections. Thread sealants are viscous compounds applied directly onto threads, providing both sealing and lubrication to ensure a leak-proof and durable joint. Both materials serve critical roles in plumbing and mechanical assemblies, with Teflon tape offering ease of use and thread sealants delivering enhanced sealing strength in high-pressure environments.

Composition and Material Differences

Teflon tape, also known as PTFE tape, is made from polytetrafluoroethylene, a synthetic fluoropolymer known for its low friction and high chemical resistance, providing an effective seal by filling thread gaps. Thread sealant, often composed of anaerobic adhesives, silicone, or other polymers, cures to form a solid, flexible bond that resists temperature changes and vibration. The material differences influence application: Teflon tape is a non-adhesive, lubricating tape, while thread sealants chemically bond to metal threads, enhancing sealing performance in more demanding environments.

Application Methods: Teflon Tape vs Thread Sealant

Teflon tape is applied by wrapping it clockwise around threaded pipe ends to create a tight seal that prevents leaks in plumbing and gas fittings. Thread sealant, typically a paste or liquid, is brushed or applied directly onto threads before assembly to fill gaps and provide a durable, chemical-resistant bond. The choice of application method depends on the specific requirements of the joint, such as temperature, pressure, and ease of disassembly.

Sealing Performance and Reliability

Teflon tape, made from polytetrafluoroethylene (PTFE), offers reliable sealing by filling pipe thread gaps and preventing leaks under moderate pressure and temperature conditions. Thread sealants, typically composed of anaerobic adhesives or synthetic compounds, provide superior sealing performance by chemically bonding to threads, ensuring enhanced durability and resistance to vibrations and high-pressure applications. In critical plumbing and industrial settings, thread sealants generally deliver higher reliability and long-term leak prevention compared to Teflon tape.

Compatibility with Pipe Materials

Teflon tape offers excellent compatibility with most common pipe materials including stainless steel, brass, and PVC, creating a reliable, non-reactive seal. Thread sealants, such as anaerobic adhesives, provide a versatile solution that bonds well with metal pipes like steel and galvanized iron but may not be suitable for plastic or softer materials. Selecting between Teflon tape and thread sealant depends on the pipe material to ensure optimal sealing performance and avoid chemical degradation or joint failure.

Pros and Cons: Teflon Tape

Teflon tape, also known as PTFE tape, offers excellent resistance to chemicals and high temperatures, making it ideal for sealing threaded pipe joints in plumbing and gas fittings. Its ease of application and low cost are significant advantages, but improper wrapping can lead to leaks or tape shredding during assembly. Unlike thread sealants, Teflon tape does not fill gaps, which may reduce sealing effectiveness in damaged or irregular threads.

Pros and Cons: Thread Sealant

Thread sealant provides excellent chemical resistance and superior sealing performance for metal pipe threads, preventing leaks under high pressure and temperature conditions. Its liquid form allows it to fill irregular thread gaps, offering better adhesion compared to Teflon tape, but it can be messier and requires curing time before assembly. However, thread sealant may complicate disassembly and cause contamination in sensitive systems, making it less convenient for frequent maintenance.

Common Uses in Plumbing and Industry

Teflon tape is widely used in plumbing for sealing pipe threads due to its ease of application and ability to prevent leaks in water and gas lines. Thread sealant, often a paste or liquid, is preferred in industrial settings for its stronger bond, filling gaps in irregular threads and providing enhanced chemical resistance. Both materials ensure secure, leak-proof connections but are chosen based on the specific requirements of pressure, temperature, and chemical exposure.

Cost Comparison and Longevity

Teflon tape typically costs less upfront compared to thread sealant, making it a budget-friendly option for sealing pipe threads. However, thread sealants often provide a longer-lasting seal, especially in high-pressure or high-temperature environments, reducing maintenance frequency over time. The longevity and performance trade-off may justify the higher initial investment in thread sealant for critical plumbing applications.

Choosing the Right Option for Your Project

Teflon tape provides a quick, clean seal for plumbing threads, ideal for small-scale or home repair projects due to its ease of use and resistance to water and chemicals. Thread sealants, often epoxy or paste-based, offer a stronger, more durable bond suited for high-pressure or industrial applications where leakage prevention is critical. Selecting between Teflon tape and thread sealant depends on project requirements such as pressure levels, chemical exposure, and the necessity for a flexible or permanent seal.

Teflon tape vs Thread sealant Infographic

materialdif.com

materialdif.com