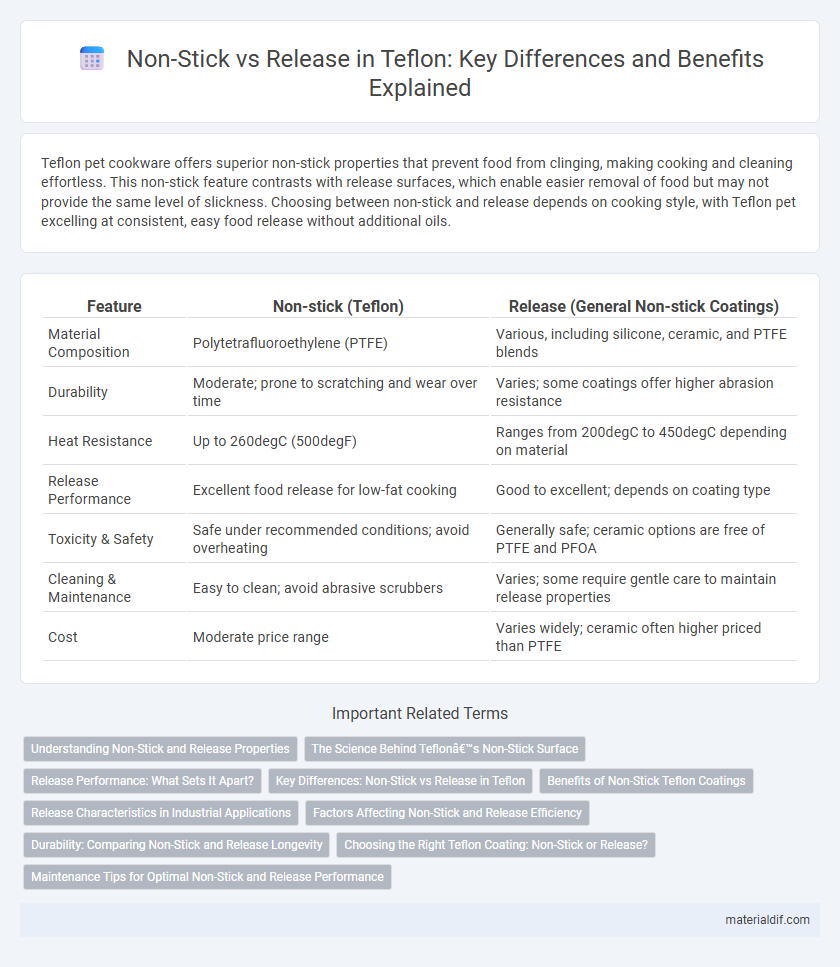

Teflon pet cookware offers superior non-stick properties that prevent food from clinging, making cooking and cleaning effortless. This non-stick feature contrasts with release surfaces, which enable easier removal of food but may not provide the same level of slickness. Choosing between non-stick and release depends on cooking style, with Teflon pet excelling at consistent, easy food release without additional oils.

Table of Comparison

| Feature | Non-stick (Teflon) | Release (General Non-stick Coatings) |

|---|---|---|

| Material Composition | Polytetrafluoroethylene (PTFE) | Various, including silicone, ceramic, and PTFE blends |

| Durability | Moderate; prone to scratching and wear over time | Varies; some coatings offer higher abrasion resistance |

| Heat Resistance | Up to 260degC (500degF) | Ranges from 200degC to 450degC depending on material |

| Release Performance | Excellent food release for low-fat cooking | Good to excellent; depends on coating type |

| Toxicity & Safety | Safe under recommended conditions; avoid overheating | Generally safe; ceramic options are free of PTFE and PFOA |

| Cleaning & Maintenance | Easy to clean; avoid abrasive scrubbers | Varies; some require gentle care to maintain release properties |

| Cost | Moderate price range | Varies widely; ceramic often higher priced than PTFE |

Understanding Non-Stick and Release Properties

Non-stick properties allow Teflon coatings to prevent food and other materials from adhering to surfaces, making cleaning and cooking more efficient. Release properties refer to Teflon's ability to facilitate easy removal of substances without damage or residue, often used in industrial molds and packaging. Understanding these distinctions helps optimize application choice between cookware and manufacturing processes for enhanced performance.

The Science Behind Teflon’s Non-Stick Surface

Teflon's non-stick surface is derived from polytetrafluoroethylene (PTFE), a polymer with extremely low surface energy, which prevents substances from bonding to it. The chemical structure of PTFE forms strong carbon-fluorine bonds, creating a smooth, inert coating that minimizes adhesion of food and other materials. This scientific property differentiates non-stick Teflon from standard release coatings by offering superior durability and resistance to chemical reactions.

Release Performance: What Sets It Apart?

Release performance in Teflon coatings is defined by its ability to prevent material adhesion, ensuring effortless separation during manufacturing processes such as molding and packaging. Unlike generic non-stick surfaces, Teflon's molecular structure provides superior release properties by minimizing surface energy and enhancing chemical resistance, which drastically reduces residue buildup. This distinct capability extends the lifespan of molds and improves product quality through consistent, contamination-free separations.

Key Differences: Non-Stick vs Release in Teflon

Non-stick Teflon coatings prevent food adhesion by creating a smooth, low-friction surface optimized for easy cooking and cleaning, while release coatings focus on minimizing material buildup on industrial molds and equipment for enhanced product demolding. Non-stick applications prioritize culinary convenience with durable fluoropolymer layers such as PTFE, whereas release coatings emphasize industrial efficiency in plastics, rubber, and composite manufacturing. Understanding these key differences enables selecting the appropriate Teflon variant based on performance requirements and end-use conditions.

Benefits of Non-Stick Teflon Coatings

Non-stick Teflon coatings offer exceptional food release, reducing the need for oils and fats, which promotes healthier cooking and easier cleanup. These coatings provide superior durability and scratch resistance compared to standard release coatings, extending cookware lifespan. Their low friction surface minimizes food adhesion, enhancing cooking performance and preserving the integrity of delicate ingredients.

Release Characteristics in Industrial Applications

Release characteristics in industrial applications of Teflon are critical for minimizing adhesion of materials during manufacturing processes, ensuring smooth detachment without residue. The inherent low surface energy and chemical inertness of Teflon facilitate superior release properties, improving cycle times and product quality in molding, coating, and adhesive processes. Optimized release performance reduces maintenance requirements and enhances operational efficiency in industries such as automotive, aerospace, and electronics manufacturing.

Factors Affecting Non-Stick and Release Efficiency

The efficiency of non-stick and release properties in Teflon coatings depends on surface roughness, coating thickness, and chemical composition. Surface energy and curing temperature significantly influence the adhesion and durability of the Teflon layer, affecting release performance. Environmental factors such as temperature changes and exposure to solvents also degrade non-stick functionality over time, reducing release efficiency.

Durability: Comparing Non-Stick and Release Longevity

Non-stick coatings typically offer strong initial performance but may degrade after extended use due to surface abrasion and heat exposure, reducing their effectiveness. Release coatings, engineered for high-temperature resistance and chemical inertness, generally maintain their properties longer under rigorous industrial conditions. Durability in non-stick versus release applications depends largely on the specific formulation and operating environment, with release coatings often preferred for prolonged service life.

Choosing the Right Teflon Coating: Non-Stick or Release?

Choosing the right Teflon coating depends on the specific application requirements: non-stick Teflon coatings prevent food or materials from adhering, making them ideal for cookware and bakeware, while release coatings are designed to provide easy separation in industrial molding and manufacturing processes. Non-stick coatings often feature polytetrafluoroethylene (PTFE) for superior durability and ease of cleaning, whereas release coatings may incorporate Perfluoroalkoxy (PFA) or Fluorinated Ethylene Propylene (FEP) for enhanced chemical resistance and high-temperature performance. Understanding the differences in composition, temperature tolerance, and surface interaction ensures optimal performance and longevity of the Teflon-coated product.

Maintenance Tips for Optimal Non-Stick and Release Performance

To maintain optimal non-stick and release performance of Teflon-coated cookware, avoid using metal utensils and abrasive cleaning pads that can damage the coating. Regularly clean with mild detergent and warm water, ensuring no residue build-up that diminishes non-stick properties. Proper storage, such as stacking cookware with protective layers, prevents surface scratches and extends the lifespan of the Teflon coating.

Non-stick vs Release Infographic

materialdif.com

materialdif.com