Teflon is a brand name widely recognized for its non-stick coatings, primarily composed of PTFE (polytetrafluoroethylene), a synthetic fluoropolymer known for its excellent chemical resistance and low friction properties. While Teflon refers to a specific product line, PTFE is the generic material used in various applications beyond cookware, including industrial seals and medical devices. Understanding this distinction helps consumers identify the quality and purpose of products labeled as Teflon or containing PTFE.

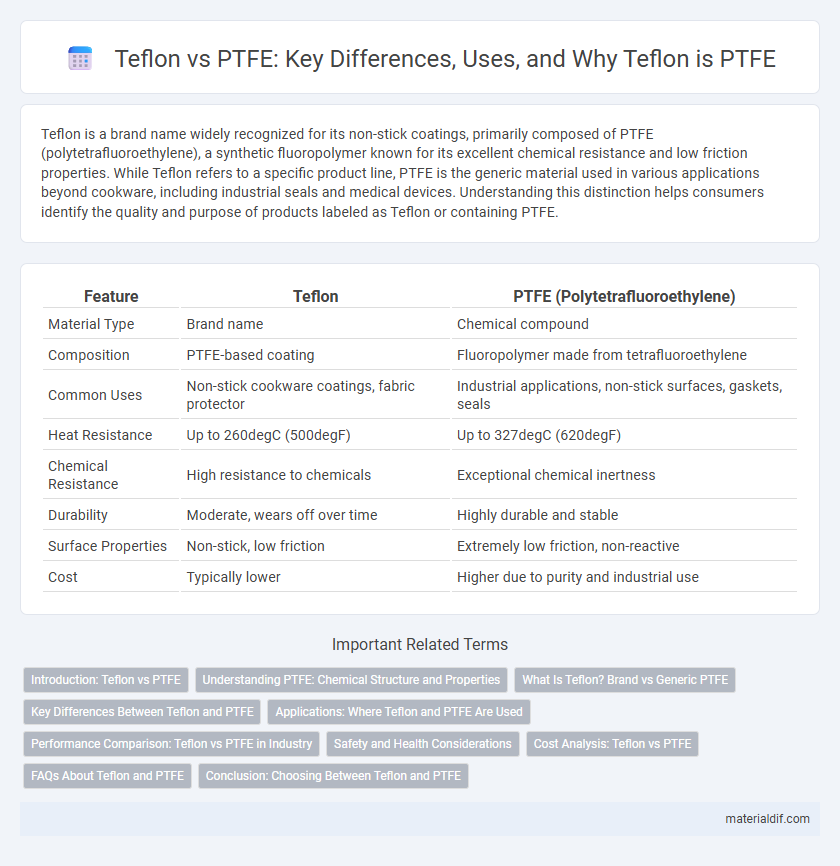

Table of Comparison

| Feature | Teflon | PTFE (Polytetrafluoroethylene) |

|---|---|---|

| Material Type | Brand name | Chemical compound |

| Composition | PTFE-based coating | Fluoropolymer made from tetrafluoroethylene |

| Common Uses | Non-stick cookware coatings, fabric protector | Industrial applications, non-stick surfaces, gaskets, seals |

| Heat Resistance | Up to 260degC (500degF) | Up to 327degC (620degF) |

| Chemical Resistance | High resistance to chemicals | Exceptional chemical inertness |

| Durability | Moderate, wears off over time | Highly durable and stable |

| Surface Properties | Non-stick, low friction | Extremely low friction, non-reactive |

| Cost | Typically lower | Higher due to purity and industrial use |

Introduction: Teflon vs PTFE

Teflon is the brand name trademarked by Chemours, representing a range of fluoropolymer products primarily composed of polytetrafluoroethylene (PTFE). PTFE is the generic name for the synthetic fluoropolymer made of tetrafluoroethylene monomers, known for its non-reactive and low friction properties. Understanding the distinction between Teflon as a trademark and PTFE as the chemical substance is essential for applications in industries like cookware, electronics, and chemical processing.

Understanding PTFE: Chemical Structure and Properties

PTFE, or polytetrafluoroethylene, is the chemical name for the polymer commonly branded as Teflon, characterized by its carbon-fluorine bonds that create a highly stable and inert molecule. This unique chemical structure results in exceptional chemical resistance, non-stick properties, and a high melting point around 327degC (621degF), making PTFE ideal for coatings, gaskets, and insulation applications. Understanding PTFE's molecular composition clarifies why Teflon exhibits superior resistance to heat, acids, and friction compared to many other polymers.

What Is Teflon? Brand vs Generic PTFE

Teflon is a trademarked brand name owned by Chemours, referring specifically to polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its non-stick and heat-resistant properties. While all Teflon products are made from PTFE, not all PTFE is sold under the Teflon brand, as generic PTFE materials are manufactured and used in various industries without the Teflon trademark. The distinction between Teflon and PTFE lies primarily in branding and licensing, with Teflon representing a specific, high-quality PTFE product recognized for coatings in cookware, industrial applications, and chemical resistance.

Key Differences Between Teflon and PTFE

Teflon is a brand name owned by Chemours, primarily associated with polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its non-stick, chemical resistance, and low friction properties. The key difference lies in the fact that PTFE is the exact chemical compound, while Teflon is the trademarked name that can also include other fluoropolymer coatings. PTFE serves as the base material, whereas Teflon may refer to various formulations and applications utilizing PTFE or related fluoropolymers.

Applications: Where Teflon and PTFE Are Used

Teflon and PTFE are widely used in non-stick cookware, chemical processing equipment, and electrical insulation due to their exceptional chemical resistance and low friction properties. PTFE is preferred in industrial applications such as seals, gaskets, and linings for pipes handling corrosive substances. Teflon-coated surfaces also enhance performance in automotive parts, aerospace components, and medical devices, offering durability and heat resistance.

Performance Comparison: Teflon vs PTFE in Industry

Teflon, a brand name for polytetrafluoroethylene (PTFE), is widely recognized for its exceptional non-stick and chemical resistance properties, making it ideal for various industrial applications. While PTFE refers to the generic polymer, Teflon products typically undergo proprietary manufacturing processes that enhance durability and thermal stability, resulting in superior performance in high-temperature and corrosive environments. Industries such as chemical processing, electronics, and automotive leverage Teflon coatings for reliable insulation and reduced friction, benefiting from its enhanced wear resistance compared to standard PTFE materials.

Safety and Health Considerations

Teflon is a brand name for a type of polytetrafluoroethylene (PTFE), commonly used in non-stick cookware and industrial applications, both known for chemical inertness and heat resistance. Safety concerns arise from overheated PTFE, which can release toxic fumes harmful to birds and humans, necessitating proper temperature control below 260degC (500degF) to prevent decomposition. Long-term exposure to perfluorooctanoic acid (PFOA), historically used in PTFE production, has raised health concerns, although modern manufacturing processes have largely eliminated PFOA from consumer products.

Cost Analysis: Teflon vs PTFE

Teflon and PTFE are often used interchangeably, but Teflon is actually a brand name for PTFE, which stands for polytetrafluoroethylene. In cost analysis, PTFE is generally more affordable when purchased in bulk or raw material form, whereas Teflon-branded products can command higher prices due to branding and proprietary manufacturing processes. Evaluating long-term expenses should factor in Teflon's higher initial cost against its proven durability and performance in demanding applications.

FAQs About Teflon and PTFE

Teflon is a brand name owned by Chemours for a type of PTFE (polytetrafluoroethylene), which is a synthetic fluoropolymer known for its non-stick properties and chemical resistance. Frequently asked questions about Teflon and PTFE often clarify that all Teflon is PTFE, but not all PTFE is branded as Teflon, emphasizing differences in application and quality standards. Common concerns include the safety of PTFE coatings at high temperatures and the differences in durability between Teflon-coated products and generic PTFE materials.

Conclusion: Choosing Between Teflon and PTFE

Teflon is the brand name for polytetrafluoroethylene (PTFE), making them chemically identical with PTFE as the generic polymer. Selecting between Teflon and PTFE depends on whether brand assurance or cost-effectiveness is prioritized, as Teflon offers trusted quality from Chemours, while PTFE is often used generically in industrial applications. Both materials provide excellent non-stick, chemical resistance, and thermal stability properties essential for cookware, coatings, and gasket manufacturing.

Teflon vs PTFE Infographic

materialdif.com

materialdif.com