Porous PTFE consists of a network of microscopic pores that offer excellent breathability and filtration capabilities, making it ideal for protective clothing and medical applications. Expanded PTFE (ePTFE) is manufactured through a stretching process that creates a unique microporous structure with enhanced strength and flexibility, commonly used in gasket materials and vascular grafts. The key difference lies in the manufacturing methods and resulting mechanical properties, where ePTFE provides superior durability and controlled pore size compared to traditional porous PTFE.

Table of Comparison

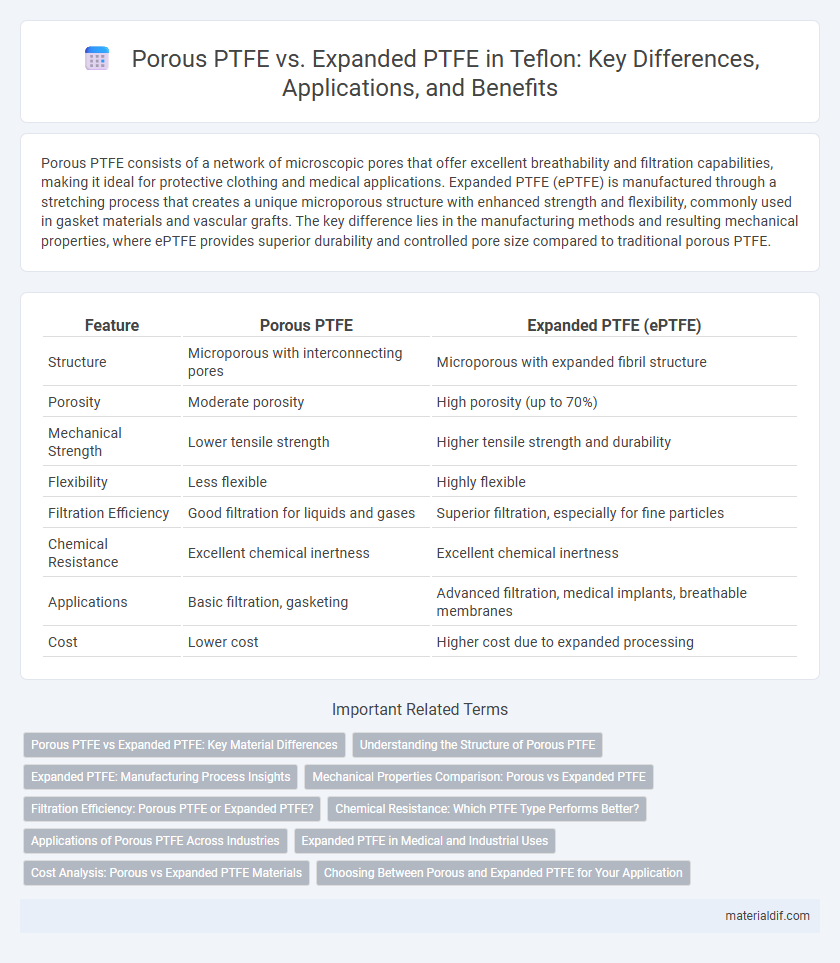

| Feature | Porous PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Structure | Microporous with interconnecting pores | Microporous with expanded fibril structure |

| Porosity | Moderate porosity | High porosity (up to 70%) |

| Mechanical Strength | Lower tensile strength | Higher tensile strength and durability |

| Flexibility | Less flexible | Highly flexible |

| Filtration Efficiency | Good filtration for liquids and gases | Superior filtration, especially for fine particles |

| Chemical Resistance | Excellent chemical inertness | Excellent chemical inertness |

| Applications | Basic filtration, gasketing | Advanced filtration, medical implants, breathable membranes |

| Cost | Lower cost | Higher cost due to expanded processing |

Porous PTFE vs Expanded PTFE: Key Material Differences

Porous PTFE is characterized by a network of open pores allowing fluid permeability, while expanded PTFE (ePTFE) features a microstructure created through mechanical stretching, resulting in high tensile strength and enhanced flexibility. ePTFE exhibits superior chemical resistance and biocompatibility, making it ideal for medical implants and filtration applications, whereas porous PTFE is commonly used in breathable membranes and gasketing. The fundamental difference lies in the manufacturing process that defines their porosity, mechanical properties, and functional uses.

Understanding the Structure of Porous PTFE

Porous PTFE features a microstructure composed of interconnected nodes and fibrils, creating a network of microscopic pores that enable gas permeability while blocking liquids. This unique architecture contrasts with expanded PTFE, which undergoes mechanical stretching to increase porosity and surface area, enhancing breathability and filtration efficiency. Understanding the nodal-fibril configuration of porous PTFE is crucial for applications requiring precise control over permeability and chemical resistance.

Expanded PTFE: Manufacturing Process Insights

Expanded PTFE (ePTFE) is produced by mechanically stretching PTFE under controlled heat and pressure conditions, creating a microstructure of interconnected fibrils and nodes that enhance porosity and flexibility. This biaxial expansion process imparts superior permeability and strength compared to porous PTFE, which is typically created through sintering techniques without structural modification. The unique manufacturing methodology of ePTFE results in a material widely used in medical implants, filtration systems, and advanced gasketing due to its exceptional durability and biocompatibility.

Mechanical Properties Comparison: Porous vs Expanded PTFE

Porous PTFE exhibits higher tensile strength and improved abrasion resistance compared to expanded PTFE, making it suitable for applications requiring durability under mechanical stress. Expanded PTFE offers superior flexibility and elongation, enabling better conformability and resilience in dynamic environments. Both materials differ in microstructure, with porous PTFE featuring interconnected pores that enhance mechanical integrity, while expanded PTFE's fibrillated network provides enhanced elasticity.

Filtration Efficiency: Porous PTFE or Expanded PTFE?

Porous PTFE exhibits superior filtration efficiency due to its uniform microporous structure, which effectively captures submicron particles while maintaining high airflow. Expanded PTFE, created by stretching PTFE, offers enhanced mechanical strength and flexibility but typically has larger pore sizes that may reduce its ability to filter ultrafine particles. For applications requiring maximum filtration performance, porous PTFE is generally preferred over expanded PTFE.

Chemical Resistance: Which PTFE Type Performs Better?

Expanded PTFE exhibits superior chemical resistance compared to porous PTFE due to its dense microstructure that minimizes chemical permeation and degradation. The expanded form maintains stability across a broader range of aggressive chemicals, including strong acids and bases, enhancing its durability in harsh environments. Porous PTFE's higher permeability can lead to reduced chemical resistance, making expanded PTFE the preferred choice for applications requiring maximal chemical inertness.

Applications of Porous PTFE Across Industries

Porous PTFE exhibits superior chemical resistance and breathability, making it ideal for filtration systems in pharmaceutical and food processing industries. Its microporous structure allows for effective gas exchange while preventing liquid penetration, widely utilized in medical implant devices and protective clothing. The material's durability and non-reactive nature support applications in environmental engineering, such as water treatment membranes and industrial air filters.

Expanded PTFE in Medical and Industrial Uses

Expanded PTFE (ePTFE) is widely utilized in medical applications due to its biocompatibility, flexibility, and microporous structure that promotes tissue integration and fluid permeability. In industrial settings, ePTFE serves as an effective sealing material and filtration membrane, offering chemical resistance, thermal stability, and durability under harsh operating conditions. Its engineered porosity enables controlled gas and liquid transfer, making ePTFE ideal for implants, surgical grafts, and high-performance industrial gaskets and filters.

Cost Analysis: Porous vs Expanded PTFE Materials

Porous PTFE typically exhibits lower manufacturing costs due to simpler processing methods, while expanded PTFE (ePTFE) involves more complex stretching and sintering, increasing production expenses. Cost analysis reveals that porous PTFE is cost-effective for applications requiring moderate filtration, whereas ePTFE justifies higher prices with superior mechanical strength and enhanced chemical resistance. Selecting between porous and expanded PTFE depends on balancing budget constraints with performance requirements in filtration and sealing applications.

Choosing Between Porous and Expanded PTFE for Your Application

Porous PTFE offers high chemical resistance and excellent filtration properties due to its interconnected void structure, making it ideal for applications requiring precision filtration and gas permeability. Expanded PTFE (ePTFE) provides enhanced mechanical strength and flexibility through mechanical stretching, suitable for gasket seals, medical implants, and breathable textiles where durability and biocompatibility are essential. Selecting between porous and expanded PTFE depends on balancing filtration efficiency, mechanical demands, and thermal stability tailored to specific application needs.

porous PTFE vs expanded PTFE Infographic

materialdif.com

materialdif.com