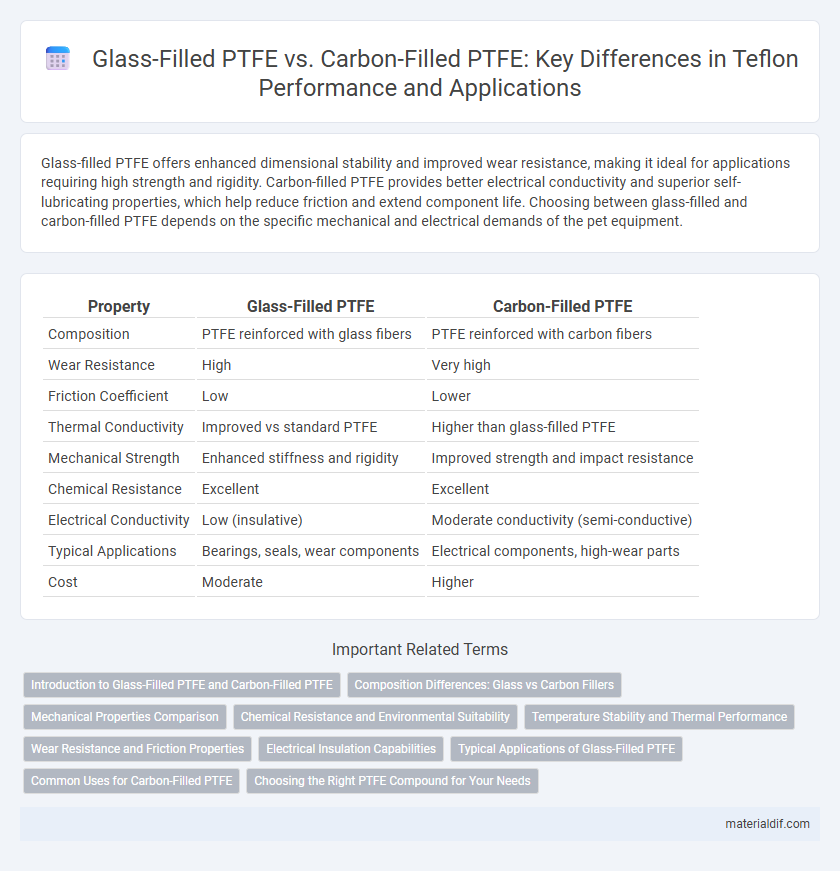

Glass-filled PTFE offers enhanced dimensional stability and improved wear resistance, making it ideal for applications requiring high strength and rigidity. Carbon-filled PTFE provides better electrical conductivity and superior self-lubricating properties, which help reduce friction and extend component life. Choosing between glass-filled and carbon-filled PTFE depends on the specific mechanical and electrical demands of the pet equipment.

Table of Comparison

| Property | Glass-Filled PTFE | Carbon-Filled PTFE |

|---|---|---|

| Composition | PTFE reinforced with glass fibers | PTFE reinforced with carbon fibers |

| Wear Resistance | High | Very high |

| Friction Coefficient | Low | Lower |

| Thermal Conductivity | Improved vs standard PTFE | Higher than glass-filled PTFE |

| Mechanical Strength | Enhanced stiffness and rigidity | Improved strength and impact resistance |

| Chemical Resistance | Excellent | Excellent |

| Electrical Conductivity | Low (insulative) | Moderate conductivity (semi-conductive) |

| Typical Applications | Bearings, seals, wear components | Electrical components, high-wear parts |

| Cost | Moderate | Higher |

Introduction to Glass-Filled PTFE and Carbon-Filled PTFE

Glass-filled PTFE features glass fibers integrated into the polytetrafluoroethylene matrix, significantly enhancing wear resistance, dimensional stability, and mechanical strength. Carbon-filled PTFE incorporates carbon particles, improving thermal conductivity, reducing friction, and providing better electrical conductivity compared to standard PTFE. Both composites address specific performance limitations of pure PTFE, making them suitable for demanding industrial applications requiring durability and low friction.

Composition Differences: Glass vs Carbon Fillers

Glass-filled PTFE contains microscopic glass fibers that enhance stiffness, dimensional stability, and wear resistance, making it ideal for applications requiring rigidity and low friction. Carbon-filled PTFE integrates fine carbon particles that improve thermal conductivity, electrical conductivity, and chemical resistance, suited for environments demanding durability under electrical or thermal stress. The primary composition difference lies in the filler type: glass fibers provide mechanical strength and wear resistance, while carbon fillers boost conductivity and chemical inertness.

Mechanical Properties Comparison

Glass-filled PTFE exhibits enhanced tensile strength and stiffness compared to carbon-filled PTFE, making it suitable for applications requiring higher mechanical rigidity. Carbon-filled PTFE offers superior wear resistance and improved thermal conductivity, which benefits components exposed to friction and elevated temperatures. Both composites maintain excellent chemical resistance and low friction, but glass-filled PTFE typically provides better dimensional stability under mechanical stress.

Chemical Resistance and Environmental Suitability

Glass-filled PTFE exhibits superior chemical resistance, maintaining stability in aggressive environments with strong acids and solvents, making it ideal for harsh chemical applications. Carbon-filled PTFE offers enhanced thermal conductivity and mechanical strength but shows slightly reduced chemical resistance compared to glass-filled variants, particularly in oxidizing agents. When selecting materials for environmental suitability, glass-filled PTFE performs better in corrosive and high-wear conditions, while carbon-filled PTFE suits applications requiring improved electrical conductivity and thermal dissipation.

Temperature Stability and Thermal Performance

Glass-Filled PTFE offers superior temperature stability with continuous operating temperatures up to 260degC and improved dimensional stability under thermal stress, making it ideal for high-temperature applications. Carbon-Filled PTFE provides enhanced thermal performance by reducing cold flow and maintaining mechanical strength at elevated temperatures, functioning effectively within a slightly lower temperature range up to 240degC. Both composites improve PTFE's thermal properties but Glass-Filled PTFE excels in withstanding prolonged high-temperature exposure while Carbon-Filled PTFE optimizes wear resistance and friction characteristics.

Wear Resistance and Friction Properties

Glass-filled PTFE exhibits superior wear resistance due to its hard glass fibers that enhance dimensional stability under mechanical stress. Carbon-filled PTFE offers lower friction coefficients, providing smoother sliding surfaces ideal for dynamic applications. Both composites optimize PTFE's performance, with glass-filled preferred in abrasive environments and carbon-filled suited for reduced friction and improved load-bearing capacity.

Electrical Insulation Capabilities

Glass-filled PTFE offers superior electrical insulation capabilities due to its high dielectric strength and excellent resistance to electrical tracking. Carbon-filled PTFE, while improving mechanical strength and thermal conductivity, exhibits reduced electrical insulation performance because of the conductive nature of carbon fillers. For applications requiring robust electrical insulation, glass-filled PTFE is the preferred choice over carbon-filled variants.

Typical Applications of Glass-Filled PTFE

Glass-filled PTFE is widely used in industrial applications requiring enhanced wear resistance and mechanical strength, such as bearings, valve seats, and seals in chemical processing equipment. Its high stiffness and improved dimensional stability make it ideal for use in heavy-load sliding components and electrical insulation parts. These properties allow Glass-filled PTFE to perform reliably in harsh environments with high temperatures and corrosive chemicals.

Common Uses for Carbon-Filled PTFE

Carbon-filled PTFE is commonly used in applications requiring improved wear resistance and low friction, such as bearings, seals, and valve components in chemical processing and automotive industries. Its enhanced mechanical strength and electrical conductivity make it ideal for use in electrical insulators and sliding parts under high-load conditions. Compared to glass-filled alternatives, carbon-filled PTFE offers better machinability and durability in dynamic environments.

Choosing the Right PTFE Compound for Your Needs

Glass-filled PTFE offers enhanced strength, wear resistance, and dimensional stability, making it ideal for applications requiring improved mechanical performance and reduced deformation. Carbon-filled PTFE provides superior electrical conductivity, lower friction, and better thermal stability, suited for applications involving electrical components or higher temperature environments. Selecting the right PTFE compound depends on specific requirements such as mechanical load, electrical conductivity, and operating temperature to ensure optimal performance and longevity.

Glass-Filled PTFE vs Carbon-Filled PTFE Infographic

materialdif.com

materialdif.com