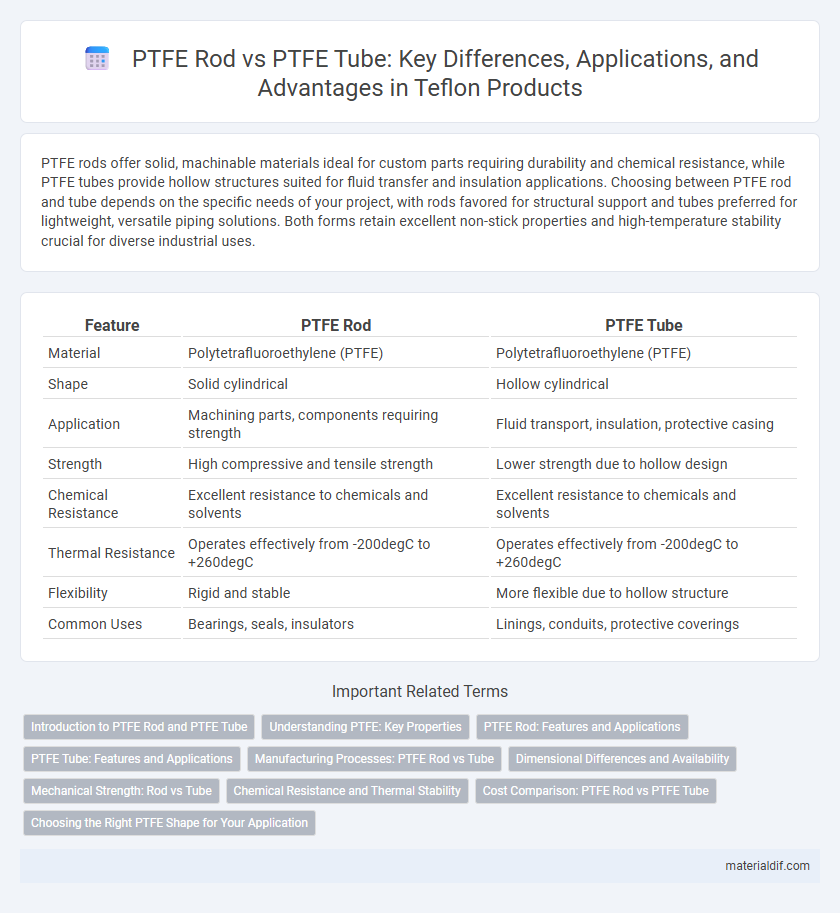

PTFE rods offer solid, machinable materials ideal for custom parts requiring durability and chemical resistance, while PTFE tubes provide hollow structures suited for fluid transfer and insulation applications. Choosing between PTFE rod and tube depends on the specific needs of your project, with rods favored for structural support and tubes preferred for lightweight, versatile piping solutions. Both forms retain excellent non-stick properties and high-temperature stability crucial for diverse industrial uses.

Table of Comparison

| Feature | PTFE Rod | PTFE Tube |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Polytetrafluoroethylene (PTFE) |

| Shape | Solid cylindrical | Hollow cylindrical |

| Application | Machining parts, components requiring strength | Fluid transport, insulation, protective casing |

| Strength | High compressive and tensile strength | Lower strength due to hollow design |

| Chemical Resistance | Excellent resistance to chemicals and solvents | Excellent resistance to chemicals and solvents |

| Thermal Resistance | Operates effectively from -200degC to +260degC | Operates effectively from -200degC to +260degC |

| Flexibility | Rigid and stable | More flexible due to hollow structure |

| Common Uses | Bearings, seals, insulators | Linings, conduits, protective coverings |

Introduction to PTFE Rod and PTFE Tube

PTFE rod and PTFE tube are versatile forms of polytetrafluoroethylene used in various industrial applications for their remarkable chemical resistance and low friction properties. PTFE rods typically serve machining and fabrication needs, offering a solid, cylindrical profile ideal for custom parts and components. PTFE tubes provide hollow, lightweight structures suited for fluid handling and insulation tasks, emphasizing ease of installation and durability in corrosive environments.

Understanding PTFE: Key Properties

PTFE rods and tubes both utilize polytetrafluoroethylene, known for its exceptional chemical resistance, low friction, and high temperature tolerance up to 260degC. PTFE rods offer solid cross-sections ideal for machining custom components, while PTFE tubes provide hollow structures suitable for fluid flow and insulation applications. Understanding these key properties helps select the right form based on mechanical strength and application-specific needs.

PTFE Rod: Features and Applications

PTFE rods offer superior mechanical strength, chemical resistance, and low friction, making them ideal for precision machining and custom components in chemical, automotive, and electrical industries. Their solid structure allows for high durability and excellent dimensional stability under extreme temperatures and corrosive environments. PTFE rods are commonly used in seals, bearings, insulators, and medical devices where reliable performance and biocompatibility are critical.

PTFE Tube: Features and Applications

PTFE tubes offer superior chemical resistance, high-temperature tolerance up to 260degC, and low friction properties, making them ideal for demanding industrial environments. These tubes are widely used in chemical processing, pharmaceutical manufacturing, and food-grade fluid transfer due to their non-reactive and non-contaminating nature. Their excellent electrical insulation and flexibility also make PTFE tubes suitable for electro-mechanical applications requiring reliable, durable tubing.

Manufacturing Processes: PTFE Rod vs Tube

PTFE rods are typically manufactured through extrusion, where molten PTFE is forced through a die to form a solid cylindrical shape, ensuring high density and structural uniformity. PTFE tubes are produced using a paste extrusion process followed by sintering, which results in a hollow profile with precise inner and outer diameters optimized for fluid transport applications. Both processes require controlled heating and cooling cycles to enhance the material's chemical resistance and mechanical properties.

Dimensional Differences and Availability

PTFE rods typically come in solid cylindrical shapes with diameters ranging from 1mm to 100mm, offering excellent strength and rigidity for machining applications. In contrast, PTFE tubes are hollow with outer diameters commonly between 3mm and 50mm and wall thicknesses that vary to suit fluid transport and insulation needs. Availability of PTFE rods is widespread in standard solid sizes, while PTFE tubes are offered in a broader range of dimensions including custom inner diameters for specialized industrial uses.

Mechanical Strength: Rod vs Tube

PTFE rods exhibit higher mechanical strength and resistance to deformation compared to PTFE tubes due to their solid cross-sectional structure, making them ideal for load-bearing applications. PTFE tubes, with a hollow core, offer greater flexibility and reduced weight but lower compressive and tensile strength. Choosing between a PTFE rod and tube depends on the specific mechanical demands, with rods favored for durability and tubes for applications where weight savings and fluid flow are critical.

Chemical Resistance and Thermal Stability

PTFE rods offer excellent chemical resistance, making them ideal for components exposed to aggressive chemicals, while PTFE tubes provide superior thermal stability, suitable for applications requiring high-temperature fluid transfer. Both PTFE rods and tubes maintain integrity in temperatures ranging from -200degC to 260degC, yet tubes often have a slight edge in withstanding thermal cycling without deformation. Selecting between PTFE rod and tube depends on the balance between chemical exposure and thermal demands in the specific industrial application.

Cost Comparison: PTFE Rod vs PTFE Tube

PTFE rods generally have a lower cost per pound compared to PTFE tubes due to simpler manufacturing processes and less material complexity. PTFE tubes require precise extrusion and additional shaping, which increases production costs and final price. For budget-sensitive applications, choosing PTFE rods can offer significant cost savings without compromising chemical resistance and thermal stability.

Choosing the Right PTFE Shape for Your Application

Choosing between PTFE rod and PTFE tube depends on the specific application requirements such as mechanical strength, chemical resistance, and dimensional constraints. PTFE rods offer solid core strength ideal for machining into custom parts, while PTFE tubes provide hollow structures for fluid or insulation uses, optimizing weight and material efficiency. Evaluating factors like load-bearing capacity, thermal properties, and installation environment ensures the right PTFE shape enhances performance and durability.

PTFE Rod vs PTFE Tube Infographic

materialdif.com

materialdif.com