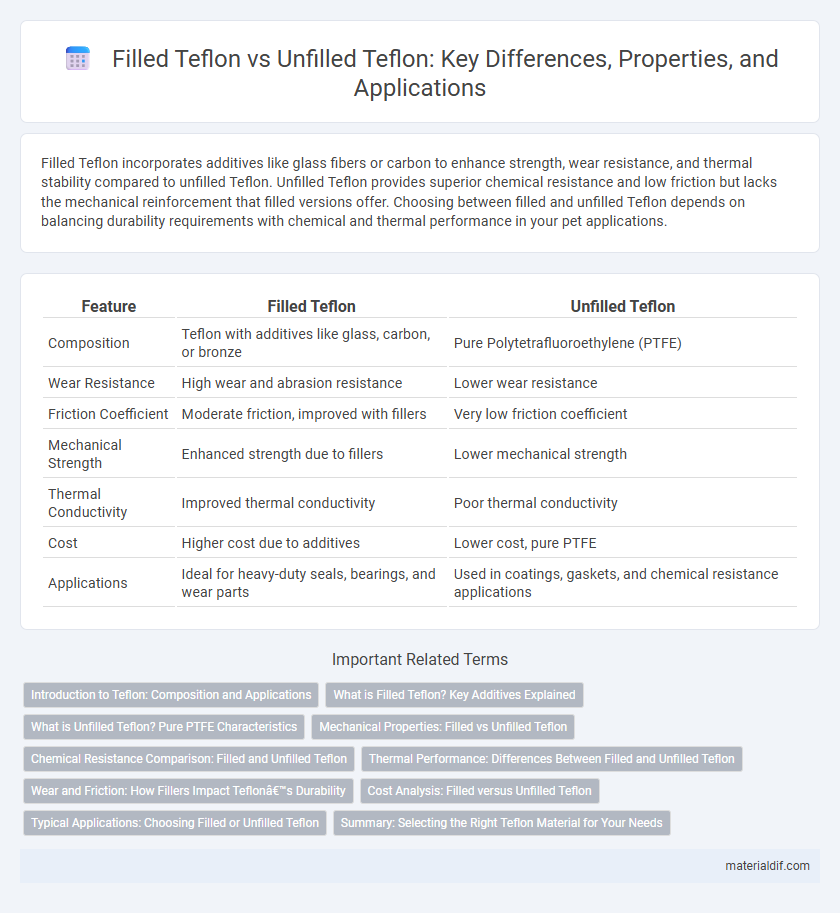

Filled Teflon incorporates additives like glass fibers or carbon to enhance strength, wear resistance, and thermal stability compared to unfilled Teflon. Unfilled Teflon provides superior chemical resistance and low friction but lacks the mechanical reinforcement that filled versions offer. Choosing between filled and unfilled Teflon depends on balancing durability requirements with chemical and thermal performance in your pet applications.

Table of Comparison

| Feature | Filled Teflon | Unfilled Teflon |

|---|---|---|

| Composition | Teflon with additives like glass, carbon, or bronze | Pure Polytetrafluoroethylene (PTFE) |

| Wear Resistance | High wear and abrasion resistance | Lower wear resistance |

| Friction Coefficient | Moderate friction, improved with fillers | Very low friction coefficient |

| Mechanical Strength | Enhanced strength due to fillers | Lower mechanical strength |

| Thermal Conductivity | Improved thermal conductivity | Poor thermal conductivity |

| Cost | Higher cost due to additives | Lower cost, pure PTFE |

| Applications | Ideal for heavy-duty seals, bearings, and wear parts | Used in coatings, gaskets, and chemical resistance applications |

Introduction to Teflon: Composition and Applications

Filled Teflon contains reinforcements such as glass fibers, carbon, or graphite, which enhance its mechanical properties, wear resistance, and thermal stability compared to unfilled Teflon. Unfilled Teflon, composed mainly of polytetrafluoroethylene (PTFE), offers excellent chemical inertness, low friction, and high temperature resistance, making it ideal for non-stick coatings and gasket materials. Industries utilize filled Teflon for demanding applications like bearing surfaces and seals where improved strength and reduced deformation are critical.

What is Filled Teflon? Key Additives Explained

Filled Teflon refers to polytetrafluoroethylene (PTFE) that is enhanced with additives such as glass fibers, carbon, graphite, bronze, or molybdenum disulfide to improve mechanical properties and wear resistance. These fillers reduce the material's tendency to deform under load, enhance thermal conductivity, and decrease friction compared to unfilled Teflon. Key additives like glass fibers boost tensile strength, while carbon and graphite fillers improve lubricity and reduce abrasion, making filled Teflon ideal for demanding industrial applications.

What is Unfilled Teflon? Pure PTFE Characteristics

Unfilled Teflon refers to pure polytetrafluoroethylene (PTFE) without any added fillers or reinforcements, offering exceptional chemical resistance and a low coefficient of friction. It features high thermal stability, excellent electrical insulation properties, and a wide operating temperature range from -200degC to 260degC. Unfilled Teflon's non-stick surface and inertness make it ideal for applications requiring pure material performance without enhanced mechanical strength.

Mechanical Properties: Filled vs Unfilled Teflon

Filled Teflon exhibits enhanced mechanical properties such as increased tensile strength, improved wear resistance, and greater dimensional stability compared to unfilled Teflon, which tends to be softer and more prone to deformation under stress. Common fillers like glass fibers, carbon, or graphite significantly boost rigidity and reduce creep in filled Teflon formulations. Unfilled Teflon offers superior chemical resistance and flexibility, making it suitable for applications where these characteristics are prioritized over mechanical strength.

Chemical Resistance Comparison: Filled and Unfilled Teflon

Filled Teflon incorporates additives such as glass fibers or carbon to enhance mechanical properties while maintaining chemical resistance, although its chemical resistance is slightly lower compared to unfilled Teflon due to potential microchannels created by fillers. Unfilled Teflon, composed purely of polytetrafluoroethylene (PTFE), exhibits superior chemical inertness and can withstand exposure to aggressive chemicals like acids, bases, and solvents without degradation. For applications demanding maximum chemical resistance, unfilled Teflon remains the preferred choice, whereas filled Teflon offers a balance between enhanced strength and adequate chemical resistance.

Thermal Performance: Differences Between Filled and Unfilled Teflon

Filled Teflon exhibits enhanced thermal conductivity compared to unfilled Teflon, allowing it to dissipate heat more efficiently in high-temperature applications. Unfilled Teflon, known for its excellent chemical resistance and low friction, has lower thermal conductivity, limiting its use in environments with extreme heat exposure. The integration of fillers such as glass or carbon fibers in filled Teflon improves thermal stability and mechanical strength, making it suitable for industrial components requiring both durability and heat resistance.

Wear and Friction: How Fillers Impact Teflon’s Durability

Filled Teflon incorporates additives such as glass fibers, carbon, or bronze, significantly enhancing its wear resistance and reducing friction compared to unfilled Teflon. These fillers improve durability by minimizing surface degradation under mechanical stress, making filled Teflon ideal for high-load and high-friction applications. Unfilled Teflon offers superior chemical resistance but tends to wear faster due to its softer polymer matrix and higher friction coefficient.

Cost Analysis: Filled versus Unfilled Teflon

Filled Teflon, incorporating additives such as glass fibers or carbon, generally incurs higher production costs compared to unfilled Teflon due to material expenses and specialized processing requirements. The enhanced mechanical properties and improved wear resistance of filled Teflon justify the increased cost in demanding industrial applications. Unfilled Teflon remains a cost-effective option for applications prioritizing chemical resistance and low friction, where mechanical strength is less critical.

Typical Applications: Choosing Filled or Unfilled Teflon

Filled Teflon, enhanced with additives like glass fiber or carbon, is typically used in applications requiring improved mechanical strength, abrasion resistance, and reduced wear, such as in bearings, gears, and valve parts. Unfilled Teflon offers superior chemical resistance, low friction, and excellent electrical insulation, making it ideal for chemical processing equipment, electrical insulation, and non-stick coatings. Selecting between filled and unfilled Teflon depends on the balance needed between mechanical durability and chemical inertness for specific industrial uses.

Summary: Selecting the Right Teflon Material for Your Needs

Filled Teflon offers enhanced mechanical strength, reduced wear, and improved thermal conductivity compared to unfilled Teflon, which provides superior chemical resistance and flexibility. Choosing between filled and unfilled Teflon depends on application-specific requirements such as load, temperature, and chemical exposure. Understanding these key properties ensures optimal performance and longevity in industrial and consumer applications.

Filled Teflon vs Unfilled Teflon Infographic

materialdif.com

materialdif.com