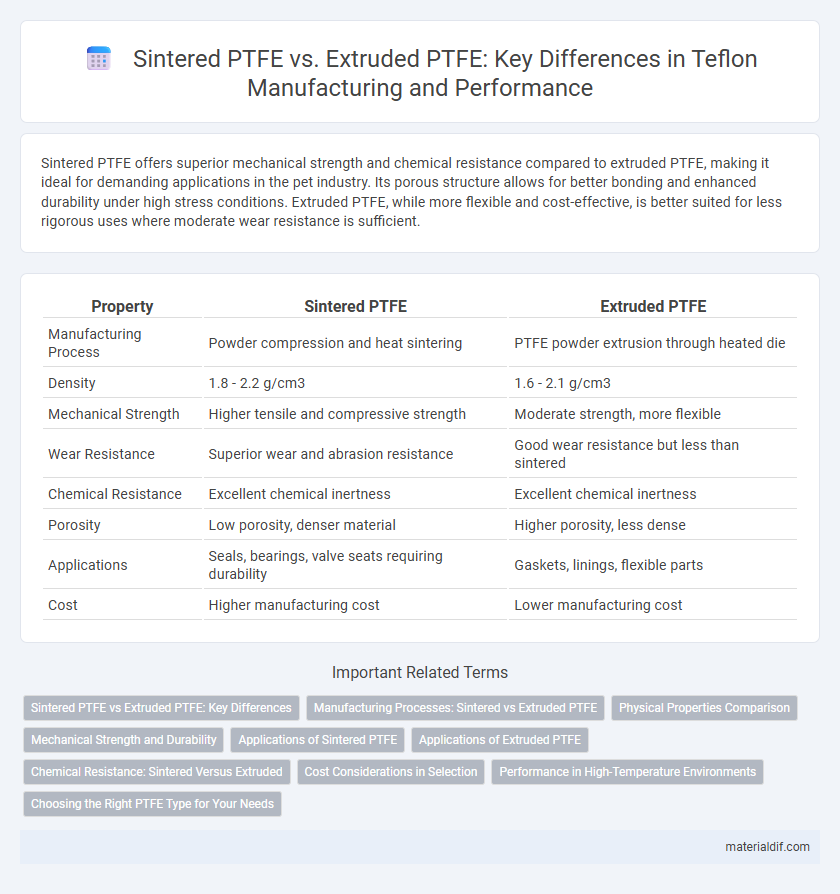

Sintered PTFE offers superior mechanical strength and chemical resistance compared to extruded PTFE, making it ideal for demanding applications in the pet industry. Its porous structure allows for better bonding and enhanced durability under high stress conditions. Extruded PTFE, while more flexible and cost-effective, is better suited for less rigorous uses where moderate wear resistance is sufficient.

Table of Comparison

| Property | Sintered PTFE | Extruded PTFE |

|---|---|---|

| Manufacturing Process | Powder compression and heat sintering | PTFE powder extrusion through heated die |

| Density | 1.8 - 2.2 g/cm3 | 1.6 - 2.1 g/cm3 |

| Mechanical Strength | Higher tensile and compressive strength | Moderate strength, more flexible |

| Wear Resistance | Superior wear and abrasion resistance | Good wear resistance but less than sintered |

| Chemical Resistance | Excellent chemical inertness | Excellent chemical inertness |

| Porosity | Low porosity, denser material | Higher porosity, less dense |

| Applications | Seals, bearings, valve seats requiring durability | Gaskets, linings, flexible parts |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

Sintered PTFE vs Extruded PTFE: Key Differences

Sintered PTFE exhibits higher mechanical strength and better chemical resistance compared to extruded PTFE, making it ideal for applications requiring enhanced durability and performance. Extruded PTFE generally offers superior dimensional accuracy and is easier to machine, but lacks the robustness found in sintered forms. The key differences lie in processing methods where sintering involves heating powdered PTFE to form a dense, uniform structure, whereas extrusion pushes molten PTFE through a die, influencing the resulting material properties.

Manufacturing Processes: Sintered vs Extruded PTFE

Sintered PTFE undergoes a manufacturing process where powdered PTFE is first compressed into a desired shape and then heated just below its melting point, resulting in a dense, uniform material with enhanced mechanical strength and chemical resistance. Extruded PTFE is produced by melting PTFE resin and forcing it through a die to create continuous shapes, offering improved dimensional accuracy and better surface finish but generally lower density compared to sintered PTFE. The choice between sintered and extruded PTFE depends on the application requirements for strength, dimensional tolerance, and surface characteristics.

Physical Properties Comparison

Sintered PTFE exhibits higher tensile strength and improved wear resistance compared to extruded PTFE, making it ideal for demanding mechanical applications. Extruded PTFE offers greater elongation at break and superior flexibility, which is advantageous for sealing and gasket uses. Both forms possess excellent chemical resistance and low friction coefficients, but sintered PTFE's enhanced density provides better dimensional stability under stress.

Mechanical Strength and Durability

Sintered PTFE exhibits superior mechanical strength and enhanced durability compared to extruded PTFE due to its unique powder compaction and high-temperature molding process, which creates a more uniform and dense microstructure. This results in higher resistance to wear, deformation, and fatigue under mechanical stress, making sintered PTFE ideal for demanding industrial applications. Extruded PTFE, while easier to machine and typically more cost-effective, generally demonstrates lower tensile strength and reduced longevity when subjected to continuous mechanical loads.

Applications of Sintered PTFE

Sintered PTFE offers superior mechanical strength and chemical resistance, making it ideal for demanding applications such as seals, gaskets, and linings in the chemical processing and pharmaceutical industries. Its enhanced durability and thermal stability allow it to perform well in high-pressure environments and extreme temperatures, commonly required in aerospace and automotive components. Sintered PTFE's resistance to wear and low friction properties also make it a preferred choice for bearing and valve seats.

Applications of Extruded PTFE

Extruded PTFE is widely used in applications requiring high mechanical strength and excellent chemical resistance, such as seals, gaskets, and valve components in the chemical and food processing industries. Its superior tensile strength and elongation properties make it ideal for dynamic environments where flexibility and durability are critical. Common applications include tubing, sheet materials, and molded parts used in aerospace and industrial machinery.

Chemical Resistance: Sintered Versus Extruded

Sintered PTFE exhibits superior chemical resistance compared to extruded PTFE due to its higher density and more uniform structure, which reduces permeability to aggressive chemicals. Extruded PTFE, while offering good chemical resistance, tends to have a less homogeneous molecular arrangement, making it more susceptible to chemical attack and degradation over time. The enhanced chemical inertness of sintered PTFE makes it ideal for applications requiring prolonged exposure to highly corrosive environments.

Cost Considerations in Selection

Sintered PTFE offers superior mechanical properties and chemical resistance but typically comes at a higher production cost compared to extruded PTFE, which is more economical for applications with less demanding performance requirements. The sintering process increases density and durability, justifying its premium price in critical sealing or insulating components where longevity and stability are essential. Cost considerations favor extruded PTFE for large-volume, cost-sensitive applications where moderate strength and flexibility suffice, making it a practical choice for general-purpose use.

Performance in High-Temperature Environments

Sintered PTFE exhibits superior mechanical strength and thermal stability compared to extruded PTFE, making it more suitable for high-temperature industrial applications up to 260degC (500degF). The porous microstructure of sintered PTFE enhances its resistance to thermal deformation and chemical attack, maintaining dimensional stability under prolonged heat exposure. In contrast, extruded PTFE, while flexible and easier to fabricate, tends to soften and lose mechanical integrity faster when subjected to continuous high temperatures.

Choosing the Right PTFE Type for Your Needs

Sintered PTFE offers superior mechanical strength and chemical resistance due to its powder compaction and high-temperature heating process, making it ideal for high-stress applications like seals and gaskets. Extruded PTFE provides better flexibility and is easier to machine, suited for less demanding uses such as tubing and insulation. Selecting the right PTFE type depends on the balance between mechanical performance and manufacturability required for your specific application.

Sintered PTFE vs Extruded PTFE Infographic

materialdif.com

materialdif.com