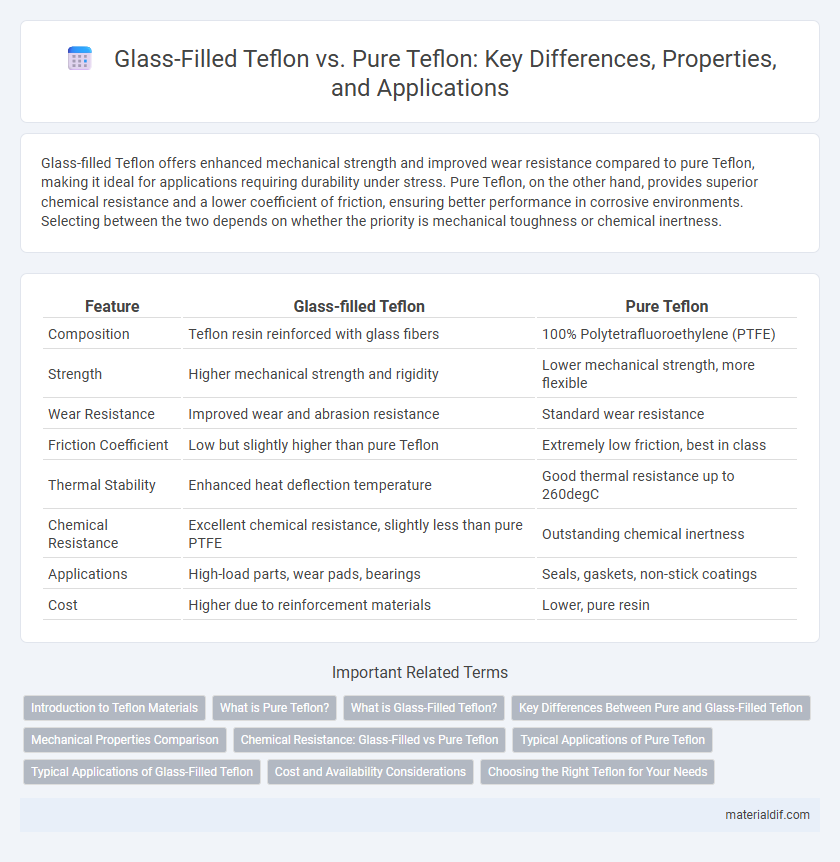

Glass-filled Teflon offers enhanced mechanical strength and improved wear resistance compared to pure Teflon, making it ideal for applications requiring durability under stress. Pure Teflon, on the other hand, provides superior chemical resistance and a lower coefficient of friction, ensuring better performance in corrosive environments. Selecting between the two depends on whether the priority is mechanical toughness or chemical inertness.

Table of Comparison

| Feature | Glass-filled Teflon | Pure Teflon |

|---|---|---|

| Composition | Teflon resin reinforced with glass fibers | 100% Polytetrafluoroethylene (PTFE) |

| Strength | Higher mechanical strength and rigidity | Lower mechanical strength, more flexible |

| Wear Resistance | Improved wear and abrasion resistance | Standard wear resistance |

| Friction Coefficient | Low but slightly higher than pure Teflon | Extremely low friction, best in class |

| Thermal Stability | Enhanced heat deflection temperature | Good thermal resistance up to 260degC |

| Chemical Resistance | Excellent chemical resistance, slightly less than pure PTFE | Outstanding chemical inertness |

| Applications | High-load parts, wear pads, bearings | Seals, gaskets, non-stick coatings |

| Cost | Higher due to reinforcement materials | Lower, pure resin |

Introduction to Teflon Materials

Glass-filled Teflon incorporates glass fibers into the polytetrafluoroethylene (PTFE) matrix, enhancing mechanical strength and wear resistance compared to pure Teflon, which consists solely of PTFE. Pure Teflon offers superior chemical inertness and low friction properties, making it ideal for applications requiring high chemical resistance and non-stick characteristics. The addition of glass fillers improves dimensional stability and load-bearing capacity, expanding the range of industrial uses for glass-filled Teflon in demanding environments.

What is Pure Teflon?

Pure Teflon, also known as polytetrafluoroethylene (PTFE), is a synthetic fluoropolymer renowned for its exceptional chemical resistance and low friction properties. It exhibits excellent non-stick qualities, high melting point, and electrical insulation, making it ideal for a wide range of industrial and consumer applications. Unlike glass-filled Teflon, pure Teflon lacks reinforcing fillers, resulting in greater flexibility but lower mechanical strength and wear resistance.

What is Glass-Filled Teflon?

Glass-filled Teflon is a composite material made by reinforcing pure Teflon (PTFE) with glass fibers, which significantly enhances its mechanical strength, wear resistance, and dimensional stability. Unlike pure Teflon, which is known for its excellent chemical resistance and low friction but relatively low structural rigidity, glass-filled Teflon offers improved load-bearing capabilities and reduced deformation under stress. This makes glass-filled Teflon particularly suitable for applications requiring both the chemical inertness of PTFE and enhanced durability, such as in high-performance bearings, seals, and industrial components.

Key Differences Between Pure and Glass-Filled Teflon

Glass-filled Teflon contains reinforcing glass fibers that significantly enhance its mechanical strength, stiffness, and wear resistance compared to pure Teflon, making it ideal for applications requiring higher durability. Pure Teflon, composed solely of polytetrafluoroethylene (PTFE), offers exceptional chemical resistance, low friction, and thermal stability but lacks the improved structural integrity found in glass-filled variants. These key differences influence material selection based on the specific needs for strength, friction, and environmental exposure in industrial use.

Mechanical Properties Comparison

Glass-filled Teflon exhibits significantly enhanced mechanical properties compared to pure Teflon, including higher tensile strength and improved wear resistance due to the incorporation of glass fibers. While pure Teflon offers excellent chemical resistance and low friction, its lower mechanical strength limits its use in high-stress applications. The glass-filled variant maintains key chemical properties while providing greater rigidity and dimensional stability, making it ideal for demanding engineering components.

Chemical Resistance: Glass-Filled vs Pure Teflon

Glass-filled Teflon offers enhanced mechanical strength but exhibits slightly reduced chemical resistance compared to pure Teflon, which maintains superior resistance to a wide range of aggressive chemicals and solvents. Pure Teflon's molecular structure provides exceptional inertness, making it ideal for highly corrosive environments where glass fibers might be compromised. When chemical resistance is paramount, pure Teflon outperforms glass-filled variants despite the latter's improved dimensional stability.

Typical Applications of Pure Teflon

Pure Teflon is widely used in applications requiring excellent chemical resistance and non-stick properties, such as lining tanks, gaskets, seals, and cookware coatings. Its low friction and high thermal stability make it ideal for components in chemical processing equipment and food handling machinery. Unlike glass-filled Teflon, pure Teflon maintains superior flexibility and dielectric properties, essential for electrical insulation and flexible tubing.

Typical Applications of Glass-Filled Teflon

Glass-filled Teflon is commonly used in applications requiring enhanced mechanical strength and dimensional stability, such as in automotive components, electrical insulation, and industrial machinery parts. Its reinforcement with glass fibers improves wear resistance and reduces creep, making it ideal for valve seats, bearing washers, and sliding components exposed to high stress. These properties enable glass-filled Teflon to perform reliably in harsh environments where pure Teflon's flexibility and chemical resistance alone may be insufficient.

Cost and Availability Considerations

Glass-filled Teflon offers enhanced mechanical strength and wear resistance compared to pure Teflon, making it more suitable for industrial applications despite a higher cost. Pure Teflon remains more widely available and cost-effective for general-purpose uses due to its simpler composition and broader manufacturing base. Cost sensitivity and application requirements dictate the choice between glass-filled and pure Teflon, with glass-filled variants typically commanding premium pricing and less immediate availability.

Choosing the Right Teflon for Your Needs

Glass-filled Teflon offers enhanced mechanical strength and improved wear resistance compared to pure Teflon, making it ideal for applications requiring greater durability and dimensional stability. Pure Teflon provides superior chemical resistance and a lower coefficient of friction, suitable for environments with aggressive chemicals or where low friction is critical. Selecting the right Teflon depends on balancing factors such as mechanical load, chemical exposure, and thermal conditions to ensure optimal performance and longevity.

Glass-filled Teflon vs Pure Teflon Infographic

materialdif.com

materialdif.com