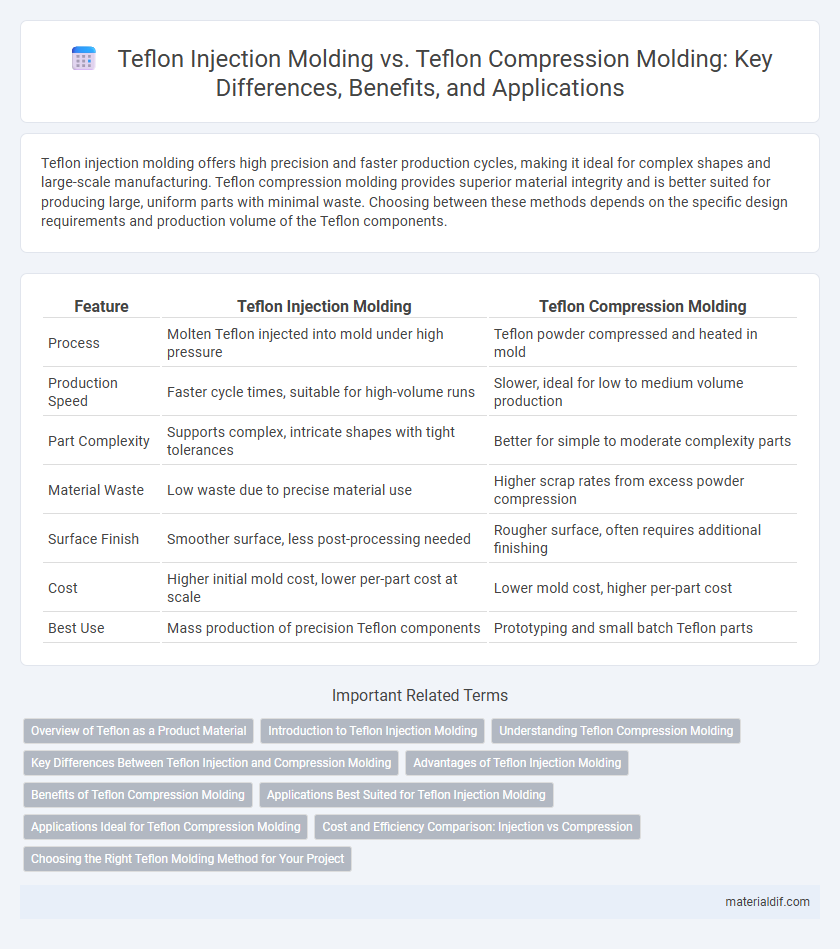

Teflon injection molding offers high precision and faster production cycles, making it ideal for complex shapes and large-scale manufacturing. Teflon compression molding provides superior material integrity and is better suited for producing large, uniform parts with minimal waste. Choosing between these methods depends on the specific design requirements and production volume of the Teflon components.

Table of Comparison

| Feature | Teflon Injection Molding | Teflon Compression Molding |

|---|---|---|

| Process | Molten Teflon injected into mold under high pressure | Teflon powder compressed and heated in mold |

| Production Speed | Faster cycle times, suitable for high-volume runs | Slower, ideal for low to medium volume production |

| Part Complexity | Supports complex, intricate shapes with tight tolerances | Better for simple to moderate complexity parts |

| Material Waste | Low waste due to precise material use | Higher scrap rates from excess powder compression |

| Surface Finish | Smoother surface, less post-processing needed | Rougher surface, often requires additional finishing |

| Cost | Higher initial mold cost, lower per-part cost at scale | Lower mold cost, higher per-part cost |

| Best Use | Mass production of precision Teflon components | Prototyping and small batch Teflon parts |

Overview of Teflon as a Product Material

Teflon, a brand name for polytetrafluoroethylene (PTFE), is prized for its exceptional chemical resistance, low friction, and high-temperature tolerance. Injection molding of Teflon allows for complex, precise shapes with shorter production cycles, while compression molding excels in producing larger, simpler parts with uniform density and superior mechanical strength. Both methods leverage Teflon's unique properties, but the choice depends on the desired product geometry, performance requirements, and manufacturing efficiency.

Introduction to Teflon Injection Molding

Teflon injection molding involves melting PTFE resin and injecting it into precise molds to form complex, high-precision components with excellent chemical resistance and low friction properties. This process enables rapid production of detailed parts with consistent dimensions, making it ideal for applications in aerospace, medical devices, and electronics. Unlike compression molding, injection molding offers superior surface finish and tighter tolerances for advanced Teflon parts.

Understanding Teflon Compression Molding

Teflon compression molding involves placing powdered PTFE resin into a heated mold, where heat and pressure fuse the material without melting it, resulting in a dense, uniform part with excellent chemical resistance and low friction. This method is preferred for producing complex shapes and larger components that require high mechanical strength and superior dimensional stability. Compression molding of Teflon is advantageous over injection molding for applications demanding consistent quality and performance under extreme chemical or thermal conditions.

Key Differences Between Teflon Injection and Compression Molding

Teflon injection molding involves melting and injecting molten PTFE into a mold cavity under high pressure, enabling precise, complex shapes with tight tolerances and shorter cycle times. In contrast, Teflon compression molding presses powdered PTFE into a heated mold, relying on pressure and temperature to sinter the material, which is better suited for simpler geometries and thicker parts. Injection molding offers superior dimensional accuracy and surface finish, while compression molding provides cost efficiency for low-volume production and larger component sizes.

Advantages of Teflon Injection Molding

Teflon injection molding offers superior precision in producing complex and intricate shapes with tight tolerances, enhancing product consistency and reducing material waste. It enables faster production cycles compared to compression molding, increasing efficiency and lowering manufacturing costs. The process also allows for better control over mold design, resulting in improved surface finish and mechanical properties of Teflon components.

Benefits of Teflon Compression Molding

Teflon compression molding offers superior control over material density and consistency, resulting in enhanced chemical resistance and non-stick properties compared to injection molding. This process enables the production of more complex, larger, and thicker parts with minimal internal stress, improving long-term durability in harsh environments. Additionally, compression molding reduces material waste and is cost-effective for low-to-medium production volumes, making it ideal for specialized Teflon components.

Applications Best Suited for Teflon Injection Molding

Teflon injection molding is best suited for producing complex, high-precision parts such as seals, gaskets, and custom components used in aerospace, medical devices, and chemical processing industries. This method offers greater design flexibility and higher production efficiency compared to compression molding, making it ideal for small to medium production runs requiring tight tolerances. Injection molding supports intricate shapes and thin walls that are challenging to achieve with Teflon compression molding.

Applications Ideal for Teflon Compression Molding

Teflon compression molding is ideal for applications requiring complex shapes with precise dimensions and excellent chemical resistance, such as seals, gaskets, and valve components used in the chemical and pharmaceutical industries. This method allows for the production of large, intricate parts with consistent density and mechanical properties, making it suitable for high-performance, custom-engineered solutions. Compression molding's ability to handle diverse Teflon grades enhances its application versatility in electrical insulation and aerospace components.

Cost and Efficiency Comparison: Injection vs Compression

Teflon injection molding offers higher production efficiency and greater precision for complex shapes, making it more cost-effective for large-scale manufacturing despite higher initial equipment expenses. Teflon compression molding presents lower upfront costs and is suitable for smaller production runs, but it involves longer cycle times and less automation, reducing overall efficiency. Choosing between the two depends on production volume demands and budget constraints, where injection molding typically lowers per-part costs at high volumes.

Choosing the Right Teflon Molding Method for Your Project

Teflon injection molding offers precise, complex geometries with high production efficiency, making it ideal for large-scale manufacturing of detailed components. In contrast, Teflon compression molding is better suited for simpler shapes and smaller production runs, providing superior material integrity and reduced waste. Selecting the right Teflon molding method depends on factors such as part complexity, volume requirements, and cost constraints to optimize performance and manufacturing efficiency.

Teflon Injection Molding vs Teflon Compression Molding Infographic

materialdif.com

materialdif.com