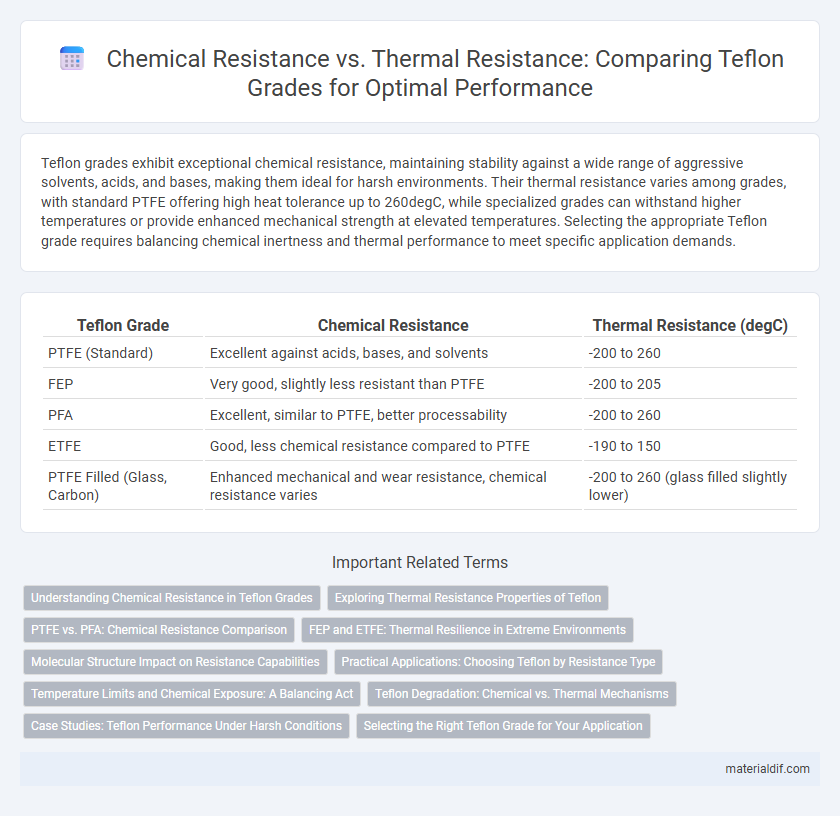

Teflon grades exhibit exceptional chemical resistance, maintaining stability against a wide range of aggressive solvents, acids, and bases, making them ideal for harsh environments. Their thermal resistance varies among grades, with standard PTFE offering high heat tolerance up to 260degC, while specialized grades can withstand higher temperatures or provide enhanced mechanical strength at elevated temperatures. Selecting the appropriate Teflon grade requires balancing chemical inertness and thermal performance to meet specific application demands.

Table of Comparison

| Teflon Grade | Chemical Resistance | Thermal Resistance (degC) |

|---|---|---|

| PTFE (Standard) | Excellent against acids, bases, and solvents | -200 to 260 |

| FEP | Very good, slightly less resistant than PTFE | -200 to 205 |

| PFA | Excellent, similar to PTFE, better processability | -200 to 260 |

| ETFE | Good, less chemical resistance compared to PTFE | -190 to 150 |

| PTFE Filled (Glass, Carbon) | Enhanced mechanical and wear resistance, chemical resistance varies | -200 to 260 (glass filled slightly lower) |

Understanding Chemical Resistance in Teflon Grades

Teflon grades exhibit exceptional chemical resistance due to their highly stable fluoropolymer structure, which effectively repels most acids, bases, and solvents. Different grades vary in chemical resistance depending on their composition, with PTFE offering superior inertness, while modified grades like PFA and FEP provide enhanced processing capabilities yet maintain strong resistance. Evaluating chemical resistance in Teflon ensures optimal material selection for applications involving aggressive chemicals, preventing degradation and extending service life.

Exploring Thermal Resistance Properties of Teflon

Teflon exhibits exceptional thermal resistance, maintaining structural integrity at temperatures up to 260degC (500degF) and with specialized grades like PFA and FEP performing reliably at continuous use temperatures around 260degC. Its unique fluoropolymer composition provides stability under thermal stress, making it ideal for high-temperature applications such as insulation in electrical components and seals in chemical processing. Teflon's ability to resist thermal degradation surpasses many polymers, ensuring longevity and performance in environments that demand consistent heat endurance.

PTFE vs. PFA: Chemical Resistance Comparison

PTFE exhibits superior chemical resistance compared to PFA, resisting a broader range of aggressive chemicals including strong acids, bases, and solvents without degradation. PFA maintains excellent chemical resistance but is slightly less resistant to highly aggressive substances, making PTFE the preferred choice for applications requiring maximum chemical inertness. Both materials offer high thermal resistance, with PTFE typically rated up to 260degC and PFA slightly higher, around 270degC, but chemical resistance remains the key differentiator in selecting the appropriate Teflon grade.

FEP and ETFE: Thermal Resilience in Extreme Environments

FEP and ETFE are prominent Teflon grades known for their exceptional thermal resilience in extreme environments, with FEP typically enduring continuous use up to 205degC and ETFE up to 150degC, making them suitable for high-temperature applications. Chemically, FEP offers superior resistance to a broad spectrum of aggressive chemicals including acids, bases, and solvents, while ETFE provides robust chemical resistance with enhanced mechanical strength and abrasion resistance. The balance between chemical resistance and thermal resistance in FEP and ETFE enables optimal performance in demanding industrial settings such as chemical processing and semiconductor manufacturing.

Molecular Structure Impact on Resistance Capabilities

Teflon's exceptional chemical and thermal resistance is largely determined by its molecular structure, specifically the strong carbon-fluorine bonds within its polytetrafluoroethylene (PTFE) chains. Variations in molecular weight and crystallinity among Teflon grades influence how well they withstand aggressive chemicals and high temperatures, with higher crystallinity enhancing thermal resistance and molecular branching affecting chemical inertness. Understanding these structural differences allows selection of appropriate Teflon grades for applications requiring optimal balance between chemical resistance and thermal stability.

Practical Applications: Choosing Teflon by Resistance Type

Teflon grades vary significantly in chemical and thermal resistance, making the choice of grade critical for specific practical applications. PTFE offers exceptional chemical resistance, ideal for corrosive environments in the chemical processing industry, while FEP and PFA grades provide enhanced thermal resistance suitable for high-temperature applications such as semiconductor manufacturing. Selecting Teflon by resistance type ensures durability and performance, optimizing materials for chemical stability or heat tolerance based on operational demands.

Temperature Limits and Chemical Exposure: A Balancing Act

Teflon grades exhibit a unique balance between chemical resistance and thermal resistance, with temperature limits ranging from -200degC to 260degC depending on the specific grade. While PTFE offers exceptional chemical inertness against acids, bases, and solvents, its mechanical properties can degrade near its upper thermal limit. Engineers must carefully select Teflon variants such as PFA or FEP to maintain chemical stability while operating within higher temperature environments in industrial applications.

Teflon Degradation: Chemical vs. Thermal Mechanisms

Teflon exhibits exceptional chemical resistance, maintaining stability against aggressive acids, bases, and solvents across a wide range of Teflon grades, with minimal degradation under chemical exposure. Thermal resistance varies by grade, with standard PTFE tolerating temperatures up to 260degC before thermal degradation initiates through chain scission and oxidation. Chemical degradation primarily involves surface erosion and swelling due to reactive agents, whereas thermal degradation results in polymer backbone breakdown and loss of mechanical integrity.

Case Studies: Teflon Performance Under Harsh Conditions

Teflon grades like PTFE exhibit exceptional chemical resistance, allowing them to withstand exposure to aggressive acids, alkalis, and solvents without degradation. Thermal resistance varies among grades, with some able to maintain structural integrity at temperatures up to 260degC, making them ideal for high-temperature industrial applications. Case studies demonstrate Teflon's reliability under harsh conditions, such as chemical processing plants and automotive engines, where sustained performance against corrosive media and thermal cycling is critical.

Selecting the Right Teflon Grade for Your Application

Teflon grades vary in chemical and thermal resistance, requiring careful selection based on application needs. PTFE offers superior chemical resistance and a broad temperature range up to 260degC, making it ideal for aggressive environments. For higher thermal resistance applications, FEP or PFA grades withstand temperatures up to 260degC with excellent chemical inertness, while PEEK provides enhanced mechanical strength and thermal stability beyond 300degC.

Chemical Resistance vs Thermal Resistance (Teflon grades) Infographic

materialdif.com

materialdif.com