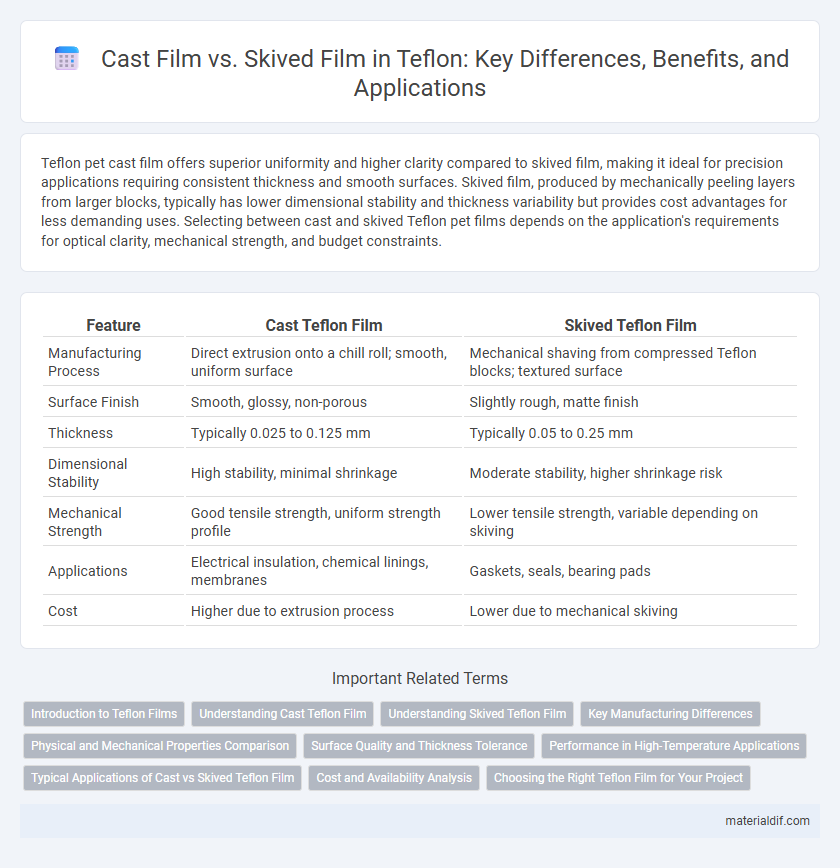

Teflon pet cast film offers superior uniformity and higher clarity compared to skived film, making it ideal for precision applications requiring consistent thickness and smooth surfaces. Skived film, produced by mechanically peeling layers from larger blocks, typically has lower dimensional stability and thickness variability but provides cost advantages for less demanding uses. Selecting between cast and skived Teflon pet films depends on the application's requirements for optical clarity, mechanical strength, and budget constraints.

Table of Comparison

| Feature | Cast Teflon Film | Skived Teflon Film |

|---|---|---|

| Manufacturing Process | Direct extrusion onto a chill roll; smooth, uniform surface | Mechanical shaving from compressed Teflon blocks; textured surface |

| Surface Finish | Smooth, glossy, non-porous | Slightly rough, matte finish |

| Thickness | Typically 0.025 to 0.125 mm | Typically 0.05 to 0.25 mm |

| Dimensional Stability | High stability, minimal shrinkage | Moderate stability, higher shrinkage risk |

| Mechanical Strength | Good tensile strength, uniform strength profile | Lower tensile strength, variable depending on skiving |

| Applications | Electrical insulation, chemical linings, membranes | Gaskets, seals, bearing pads |

| Cost | Higher due to extrusion process | Lower due to mechanical skiving |

Introduction to Teflon Films

Teflon films, known for their exceptional chemical resistance and non-stick properties, come primarily in cast and skived forms, each offering unique manufacturing advantages. Cast Teflon films are produced by pouring molten resin onto a casting surface, resulting in a smoother, more uniform thickness ideal for precision applications. Skived films are mechanically shaved from Teflon rods or blocks, providing thicker, denser sheets suitable for heavy-duty industrial uses where durability is critical.

Understanding Cast Teflon Film

Cast Teflon film is produced by spreading molten polytetrafluoroethylene (PTFE) resin onto a chilled drum, resulting in a smooth, uniform thickness with superior tensile strength and chemical resistance. Unlike skived film, which is sliced from solid PTFE blocks and may have surface irregularities, cast film offers enhanced clarity and flexibility, making it ideal for applications requiring consistent dielectric properties and high-performance insulation. The manufacturing process of cast film ensures minimal porosity and superior dimensional stability, supporting advanced uses in electronics, gasketing, and protective coatings.

Understanding Skived Teflon Film

Skived Teflon film offers enhanced dimensional stability and uniform thickness compared to cast film, making it ideal for precision applications. The skiving process mechanically slices thin layers from extruded Teflon blocks, resulting in smooth surfaces and superior mechanical properties. Understanding these differences is crucial for industries requiring high-performance non-stick, chemical-resistant films with consistent quality.

Key Manufacturing Differences

Cast Teflon film is produced by pouring molten polymer onto a chilled casting roll, creating a uniform and highly pure film with excellent dimensional stability and smooth surface finish. Skived Teflon film involves slicing thin layers from a solid block of extruded PTFE, resulting in films with superior mechanical strength and higher porosity due to the fibrillated microstructure. Key manufacturing differences include cast film's reliance on controlled cooling and solidification for consistency, whereas skived film depends on precise mechanical slicing, impacting thickness uniformity and surface texture.

Physical and Mechanical Properties Comparison

Cast Teflon films exhibit superior uniformity and enhanced elongation at break compared to skived films, making them ideal for applications requiring high flexibility. Skived Teflon films demonstrate higher tensile strength and improved thickness control, beneficial for precision components and seals. The choice between cast and skived Teflon films depends on the required balance between mechanical strength and flexibility for specific industrial uses.

Surface Quality and Thickness Tolerance

Cast Teflon films exhibit superior surface quality with a smooth, uniform texture ideal for applications requiring high clarity and consistent friction properties. Thickness tolerance in cast films is tightly controlled, typically within +-0.0005 inches, ensuring precise dimensional stability. Skived Teflon films may have minor surface irregularities due to the mechanical peeling process and a slightly wider thickness tolerance, often around +-0.001 inches, making them suitable for less visually critical applications.

Performance in High-Temperature Applications

Cast Teflon films exhibit superior dimensional stability and higher thermal resistance at elevated temperatures compared to skived films, making them ideal for prolonged exposure in harsh thermal environments. Skived Teflon films, while thinner and more uniform, tend to have lower heat tolerance and may deform under sustained high-temperature conditions. Performance in high-temperature applications strongly favors cast films due to their enhanced molecular alignment and resistance to thermal degradation.

Typical Applications of Cast vs Skived Teflon Film

Cast Teflon film is commonly used in electrical insulation, gasketing, and chemical processing due to its high purity and excellent dielectric properties. Skived Teflon film finds typical applications in sealing, gasketing, and mechanical insulation where flexibility and conformability to complex surfaces are essential. Both types provide superior chemical resistance and temperature tolerance, but cast film is preferred for uniform thickness and optical clarity, while skived film excels in thin, flexible layers.

Cost and Availability Analysis

Cast Teflon films typically incur higher production costs due to the slower, more precise manufacturing process, resulting in premium pricing but superior surface finish and uniformity. Skived Teflon films offer a cost-effective alternative with rapid production capabilities and wider availability, although minor surface imperfections may be present. Industries requiring large volumes at lower costs often prefer skived films, while applications demanding high-quality finishes favor cast films despite the increased expense.

Choosing the Right Teflon Film for Your Project

Cast Teflon film offers superior chemical resistance and dimensional stability, making it ideal for applications requiring durability and precision. Skived Teflon film provides a thinner, more flexible option with excellent insulation properties suitable for tight tolerances and intricate designs. Choosing the right Teflon film depends on project-specific needs such as thickness, flexibility, and environmental exposure.

cast film vs skived film Infographic

materialdif.com

materialdif.com