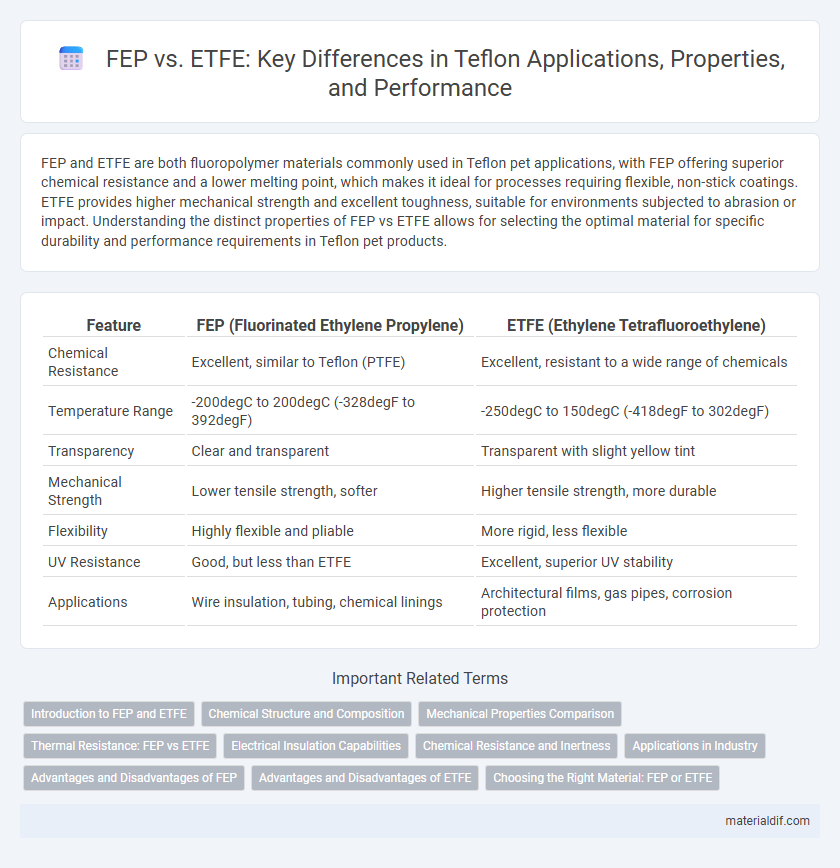

FEP and ETFE are both fluoropolymer materials commonly used in Teflon pet applications, with FEP offering superior chemical resistance and a lower melting point, which makes it ideal for processes requiring flexible, non-stick coatings. ETFE provides higher mechanical strength and excellent toughness, suitable for environments subjected to abrasion or impact. Understanding the distinct properties of FEP vs ETFE allows for selecting the optimal material for specific durability and performance requirements in Teflon pet products.

Table of Comparison

| Feature | FEP (Fluorinated Ethylene Propylene) | ETFE (Ethylene Tetrafluoroethylene) |

|---|---|---|

| Chemical Resistance | Excellent, similar to Teflon (PTFE) | Excellent, resistant to a wide range of chemicals |

| Temperature Range | -200degC to 200degC (-328degF to 392degF) | -250degC to 150degC (-418degF to 302degF) |

| Transparency | Clear and transparent | Transparent with slight yellow tint |

| Mechanical Strength | Lower tensile strength, softer | Higher tensile strength, more durable |

| Flexibility | Highly flexible and pliable | More rigid, less flexible |

| UV Resistance | Good, but less than ETFE | Excellent, superior UV stability |

| Applications | Wire insulation, tubing, chemical linings | Architectural films, gas pipes, corrosion protection |

Introduction to FEP and ETFE

FEP (fluorinated ethylene propylene) and ETFE (ethylene tetrafluoroethylene) are both versatile fluoropolymers known for their exceptional chemical resistance, high-temperature tolerance, and electrical insulation properties. FEP offers excellent flexibility and non-stick characteristics, making it ideal for applications in wire insulation and chemical processing, while ETFE is recognized for its superior mechanical strength and durability, commonly used in architectural coatings and aerospace components. Understanding the distinct molecular structures and performance profiles of FEP and ETFE helps optimize material selection for specific industrial needs.

Chemical Structure and Composition

FEP (fluorinated ethylene propylene) consists of a copolymer of hexafluoropropylene and tetrafluoroethylene, providing a highly fluorinated, chemically inert backbone with excellent resistance to corrosive substances. ETFE (ethylene tetrafluoroethylene) is a copolymer composed of ethylene and tetrafluoroethylene, featuring alternating ethylene and fluorine-substituted ethylene units that impart distinct flexibility and robustness while maintaining strong chemical resistance. The differing ratios and arrangement of fluorine atoms in FEP and ETFE polymers directly influence their thermal stability, mechanical properties, and chemical inertness, making each suitable for specific industrial applications.

Mechanical Properties Comparison

FEP (Fluorinated Ethylene Propylene) exhibits excellent flexibility and chemical resistance, with a tensile strength ranging from 20 to 30 MPa and elongation at break up to 300%, making it suitable for applications requiring high elasticity. ETFE (Ethylene Tetrafluoroethylene) offers superior mechanical strength with a tensile strength of approximately 45 MPa and lower elongation at break around 150%, providing enhanced abrasion resistance and impact resistance for structural uses. Both fluoropolymers maintain high thermal stability and UV resistance, but ETFE's higher modulus of elasticity makes it preferable for demanding mechanical environments.

Thermal Resistance: FEP vs ETFE

FEP (Fluorinated Ethylene Propylene) offers excellent thermal resistance with a continuous operating temperature up to 200degC (392degF), suitable for high-temperature industrial applications. ETFE (Ethylene Tetrafluoroethylene) provides superior thermal resistance, maintaining performance at temperatures up to 150degC (302degF) continuously and brief exposure up to 200degC, making it ideal for environments requiring durability under thermal stress. The choice between FEP and ETFE depends on the specific thermal tolerance needed, with FEP favored for higher temperature endurance and ETFE for balanced thermal and mechanical properties.

Electrical Insulation Capabilities

FEP (Fluorinated Ethylene Propylene) offers superior electrical insulation with a dielectric constant around 2.1 and excellent resistance to high voltages, making it ideal for demanding electrical applications. ETFE (Ethylene Tetrafluoroethylene) features a slightly higher dielectric constant near 2.6 but delivers robust insulation combined with greater mechanical strength and abrasion resistance. Both materials exhibit low dielectric loss and high breakdown voltage, yet FEP is preferred in ultra-pure electrical insulation environments due to its exceptional chemical inertness and clarity.

Chemical Resistance and Inertness

FEP (fluorinated ethylene propylene) exhibits exceptional chemical resistance, maintaining stability against aggressive acids, bases, and solvents across a wide temperature range due to its fully fluorinated polymer structure. ETFE (ethylene tetrafluoroethylene) also provides excellent chemical inertness but shows slightly lower resistance to strong acids and alkalis compared to FEP, making it more suitable for mechanical applications requiring toughness alongside chemical stability. Both polymers ensure minimal interaction with corrosive substances, but FEP's superior chemical resistance and inertness make it the preferred choice for highly corrosive environments.

Applications in Industry

FEP (fluorinated ethylene propylene) is widely used in the chemical processing industry for lining pipes and tanks due to its excellent chemical resistance and non-stick properties. ETFE (ethylene tetrafluoroethylene) finds extensive applications in the construction sector for architectural membranes and roofing films because of its high tensile strength and UV resistance. Both fluoropolymers are essential in the electrical industry, with FEP preferred for wire insulation and ETFE for protective coatings in harsh environments.

Advantages and Disadvantages of FEP

FEP (fluorinated ethylene propylene) offers superior chemical resistance and excellent clarity compared to ETFE (ethylene tetrafluoroethylene), making it ideal for applications requiring transparency and non-reactivity. However, FEP has a lower mechanical strength and temperature resistance, limiting its use in high-stress or high-temperature environments relative to ETFE. Its ease of processing and self-lubricating properties provide advantages in coating and insulation applications, but it is generally more expensive than ETFE.

Advantages and Disadvantages of ETFE

ETFE offers exceptional chemical resistance and high mechanical strength, making it ideal for applications requiring durability and long-term weather resistance. Its lightweight nature and excellent UV transparency provide advantages over FEP in architectural and solar panel uses. However, ETFE's lower melting point and higher cost can limit its suitability for high-temperature or budget-sensitive projects.

Choosing the Right Material: FEP or ETFE

FEP offers superior chemical resistance and excellent transparency, making it ideal for applications requiring high purity and visibility. ETFE provides greater mechanical strength and abrasion resistance, suitable for demanding structural coatings and corrosion-resistant linings. Selecting between FEP and ETFE depends on balancing the need for chemical inertness with mechanical durability in specific environmental conditions.

FEP vs ETFE Infographic

materialdif.com

materialdif.com