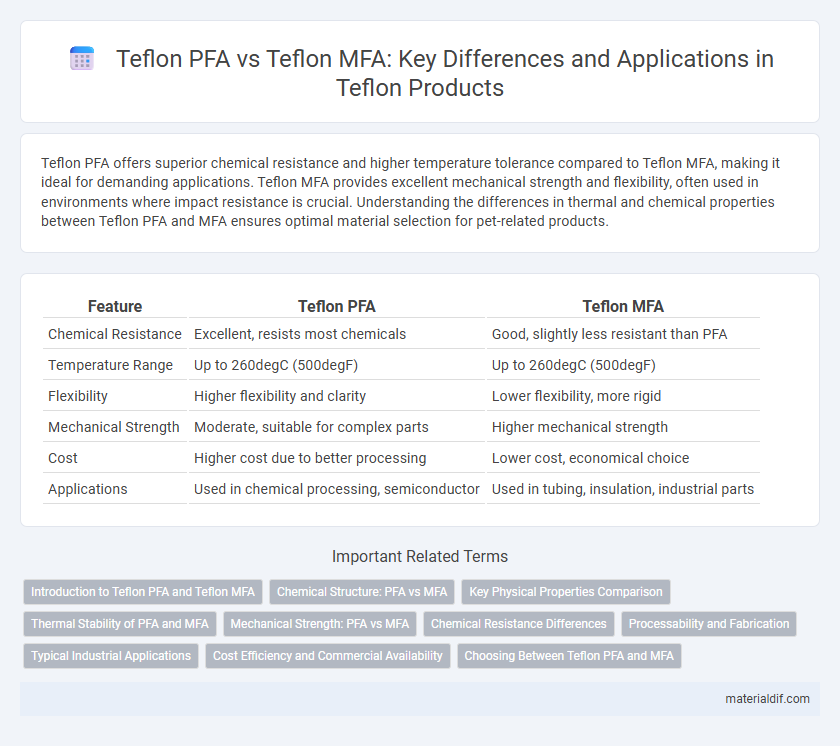

Teflon PFA offers superior chemical resistance and higher temperature tolerance compared to Teflon MFA, making it ideal for demanding applications. Teflon MFA provides excellent mechanical strength and flexibility, often used in environments where impact resistance is crucial. Understanding the differences in thermal and chemical properties between Teflon PFA and MFA ensures optimal material selection for pet-related products.

Table of Comparison

| Feature | Teflon PFA | Teflon MFA |

|---|---|---|

| Chemical Resistance | Excellent, resists most chemicals | Good, slightly less resistant than PFA |

| Temperature Range | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Flexibility | Higher flexibility and clarity | Lower flexibility, more rigid |

| Mechanical Strength | Moderate, suitable for complex parts | Higher mechanical strength |

| Cost | Higher cost due to better processing | Lower cost, economical choice |

| Applications | Used in chemical processing, semiconductor | Used in tubing, insulation, industrial parts |

Introduction to Teflon PFA and Teflon MFA

Teflon PFA (Perfluoroalkoxy) offers excellent chemical resistance and high-temperature stability, making it ideal for use in linings, tubing, and semiconductor applications. Teflon MFA (Modified Fluoropolymer Alloy) provides enhanced mechanical strength and improved flexibility while maintaining high chemical inertness and non-stick properties. Both materials belong to the fluoropolymer family but differ in performance characteristics suited to specific industrial and chemical environments.

Chemical Structure: PFA vs MFA

Teflon PFA (Perfluoroalkoxy) features a fully fluorinated carbon backbone with perfluoroalkoxy side chains, providing enhanced chemical resistance and flexibility. In contrast, Teflon MFA (Modified Fluoropolymer Acid) incorporates modified acid groups within its polymer chain, offering improved adhesion and thermal stability compared to PFA. The key chemical difference lies in PFA's symmetrical perfluoroalkoxy structure versus MFA's acid-modified backbone, influencing their specific performance in harsh chemical environments.

Key Physical Properties Comparison

Teflon PFA (Perfluoroalkoxy) offers superior chemical resistance and higher thermal stability, with a melting point around 305degC, compared to Teflon MFA (Modified Fluoropolymer), which exhibits enhanced mechanical strength but slightly lower chemical resistance and melts near 260degC. PFA demonstrates excellent flexibility and clarity, making it ideal for applications requiring transparency and high purity, whereas MFA provides better dimensional stability and lower thermal expansion, suited for demanding structural uses. Both materials maintain non-stick properties and electrical insulation, but PFA's fluorinated ether backbone leads to improved fluidity during processing compared to MFA's partially crystalline structure.

Thermal Stability of PFA and MFA

Teflon PFA (Perfluoroalkoxy) exhibits superior thermal stability with an operating temperature range up to 260degC, making it ideal for high-temperature applications requiring chemical resistance and flexibility. In contrast, Teflon MFA (Modified Fluoropolymer Alloy) offers thermal stability up to approximately 240degC, trading some heat resistance for enhanced mechanical properties and stress crack resistance. The enhanced thermal endurance of PFA ensures its preference in environments involving sustained exposure to elevated temperatures.

Mechanical Strength: PFA vs MFA

Teflon PFA exhibits superior mechanical strength compared to Teflon MFA, offering enhanced durability and resistance to deformation under stress. PFA's molecular structure provides better impact resistance and higher tensile strength, making it suitable for demanding industrial applications. In contrast, MFA has lower mechanical strength, limiting its use in environments requiring high structural integrity.

Chemical Resistance Differences

Teflon PFA (perfluoroalkoxy) exhibits superior chemical resistance compared to Teflon MFA (modified fluoropolymer) due to its fully fluorinated polymer chain and higher molecular weight, which enhance stability against aggressive acids and solvents. MFA shows adequate resistance but can degrade when exposed to highly oxidizing chemicals or strong bases over extended periods. PFA's enhanced fluorine content and uniform molecular structure make it the preferred choice for applications demanding extreme chemical durability.

Processability and Fabrication

Teflon PFA (Perfluoroalkoxy) offers superior processability with easier melt flow and higher thermal stability, making it ideal for complex fabrication processes such as injection molding and extrusion. Teflon MFA (Modified FEP) provides improved flexibility and chemical resistance but has a narrower processing window, which can limit its use in high-precision fabrication techniques. Manufacturers prefer PFA when consistent melting behavior and excellent durability are required, while MFA is chosen for applications needing enhanced mechanical resilience and resistance to harsh environments.

Typical Industrial Applications

Teflon PFA (Perfluoroalkoxy) is widely used in industries requiring high chemical resistance and superior thermal stability, such as chemical processing, semiconductor manufacturing, and pharmaceutical production. Teflon MFA (Modified Fluoropolymer Amorphous) is preferred for applications demanding excellent electrical insulation properties and mechanical strength, including electrical components and precision mechanical parts. Both materials offer non-stick properties and corrosion resistance, but PFA excels in high-temperature fluid handling, while MFA is tailored for intricate components with tight dimensional tolerances.

Cost Efficiency and Commercial Availability

Teflon PFA offers superior chemical resistance and high-temperature performance but comes at a higher cost, making it less cost-efficient compared to Teflon MFA, which provides a more affordable alternative with slightly reduced thermal stability. Teflon MFA's broader commercial availability and lower manufacturing expenses make it a preferred choice for large-scale applications requiring cost-effective fluoropolymer solutions. Businesses prioritizing budget constraints while maintaining acceptable performance often opt for Teflon MFA due to its favorable price-to-performance ratio and widespread market presence.

Choosing Between Teflon PFA and MFA

Teflon PFA (Perfluoroalkoxy) offers superior chemical resistance and higher temperature tolerance up to 260degC, making it ideal for corrosive environments and stringent applications. In comparison, Teflon MFA (Modified Fluoroalkoxy) provides excellent mechanical strength and toughness with slightly lower temperature resistance around 240degC, suitable for demanding mechanical stress scenarios. Selecting between Teflon PFA and MFA depends on balancing extreme chemical stability needs with mechanical durability requirements in specific industrial applications.

Teflon PFA vs Teflon MFA Infographic

materialdif.com

materialdif.com