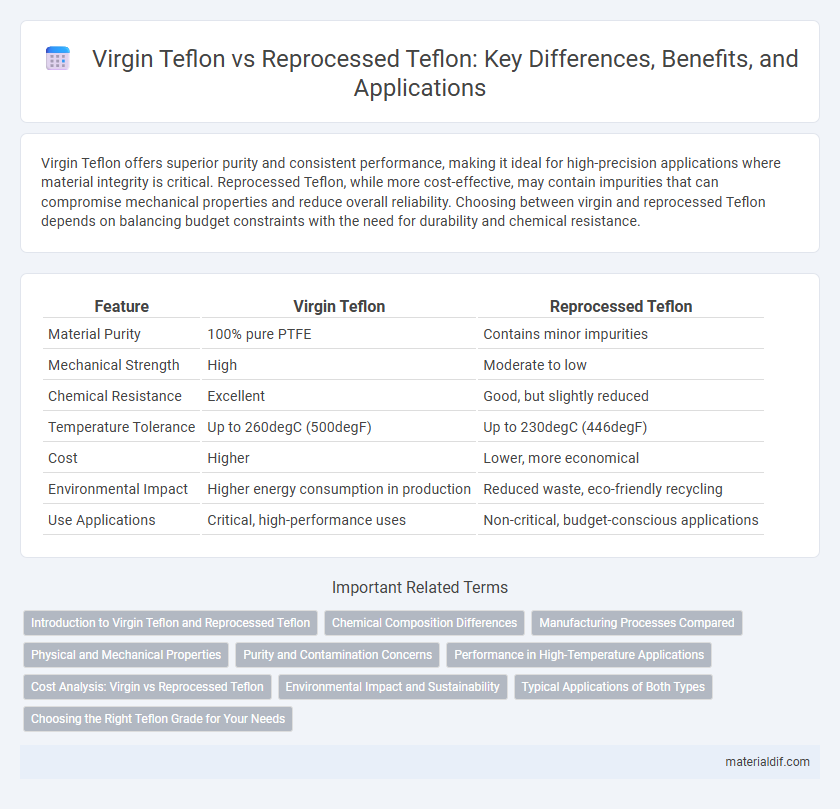

Virgin Teflon offers superior purity and consistent performance, making it ideal for high-precision applications where material integrity is critical. Reprocessed Teflon, while more cost-effective, may contain impurities that can compromise mechanical properties and reduce overall reliability. Choosing between virgin and reprocessed Teflon depends on balancing budget constraints with the need for durability and chemical resistance.

Table of Comparison

| Feature | Virgin Teflon | Reprocessed Teflon |

|---|---|---|

| Material Purity | 100% pure PTFE | Contains minor impurities |

| Mechanical Strength | High | Moderate to low |

| Chemical Resistance | Excellent | Good, but slightly reduced |

| Temperature Tolerance | Up to 260degC (500degF) | Up to 230degC (446degF) |

| Cost | Higher | Lower, more economical |

| Environmental Impact | Higher energy consumption in production | Reduced waste, eco-friendly recycling |

| Use Applications | Critical, high-performance uses | Non-critical, budget-conscious applications |

Introduction to Virgin Teflon and Reprocessed Teflon

Virgin Teflon refers to pure, unused polytetrafluoroethylene (PTFE) resin known for its exceptional chemical resistance, low friction, and high-temperature tolerance, making it ideal for critical industrial applications. Reprocessed Teflon is derived from previously used or scrap PTFE material that is cleaned, ground, and remelted to regain functional properties, often employed in less demanding environments to reduce costs. The key distinction lies in the molecular integrity and performance consistency, with virgin Teflon offering superior purity and mechanical performance compared to reprocessed variants.

Chemical Composition Differences

Virgin Teflon exhibits a pure polytetrafluoroethylene (PTFE) polymer structure with consistent molecular weight and minimal impurities, ensuring superior chemical inertness and thermal stability. Reprocessed Teflon often contains degraded polymer chains and residual contaminants from previous usage or recycling processes, which can alter its fluorine-to-carbon ratio and compromise its chemical resistance. These compositional differences directly impact the material's performance in high-demand applications involving aggressive chemicals or extreme temperatures.

Manufacturing Processes Compared

Virgin Teflon is produced through a polymerization process using pure tetrafluoroethylene monomers, resulting in a high-purity, uniform fluoropolymer with superior chemical resistance and mechanical properties. Reprocessed Teflon involves recycling scrap or off-spec material that is remelted and extruded, which can introduce impurities and affect molecular integrity, potentially reducing performance consistency. Manufacturing processes for virgin Teflon emphasize strict control over reaction conditions and monomer quality, whereas reprocessed Teflon prioritizes material recovery efficiency, often at the cost of decreased polymer chain uniformity.

Physical and Mechanical Properties

Virgin Teflon exhibits superior mechanical strength, chemical resistance, and thermal stability compared to reprocessed Teflon, which can have compromised tensile strength and reduced elongation at break due to degradation during recycling. The physical properties of virgin Teflon, such as higher purity and molecular weight, ensure consistent performance in demanding applications, whereas reprocessed Teflon may exhibit increased porosity and altered crystallinity impacting wear resistance and dielectric properties. Choosing virgin Teflon is critical for applications requiring maximum durability, chemical inertness, and reliable mechanical performance.

Purity and Contamination Concerns

Virgin Teflon is manufactured directly from tetrafluoroethylene monomers, ensuring maximum purity and consistent fluoropolymer properties, while reprocessed Teflon may contain trace contaminants and degraded polymer chains due to previous use and melting cycles. Purity in virgin Teflon enhances non-reactivity, chemical resistance, and mechanical strength, critical for applications in aerospace, medical devices, and food processing. Contamination concerns in reprocessed Teflon include potential exposure to foreign particles, reduced thermal stability, and compromised dielectric properties, which can affect product reliability and safety.

Performance in High-Temperature Applications

Virgin Teflon exhibits superior performance in high-temperature applications due to its consistent molecular structure, ensuring enhanced thermal stability and resistance to degradation. Reprocessed Teflon, while cost-effective, often contains impurities and altered polymer chains that can compromise heat resistance and reduce lifespan under extreme conditions. For critical uses requiring reliable insulation or chemical resistance at elevated temperatures, virgin Teflon remains the preferred choice.

Cost Analysis: Virgin vs Reprocessed Teflon

Virgin Teflon offers superior purity and consistent performance but comes at a higher cost due to its manufacturing process from raw materials. Reprocessed Teflon significantly reduces expenses by recycling scrap or used material, lowering raw material costs and minimizing waste. Cost analysis reveals that while virgin Teflon ensures optimal quality in critical applications, reprocessed Teflon presents a cost-effective alternative for non-critical uses without compromising essential properties.

Environmental Impact and Sustainability

Virgin Teflon is produced from raw tetrafluoroethylene monomers, resulting in high chemical purity and performance but involving significant energy consumption and greenhouse gas emissions during manufacturing. Reprocessed Teflon, derived from recycled or scrap material, reduces landfill waste and conserves resources, promoting a more sustainable lifecycle with lower carbon footprint. Choosing reprocessed Teflon supports circular economy principles by minimizing environmental impact and enhancing material reuse without substantially compromising product quality.

Typical Applications of Both Types

Virgin Teflon is widely used in critical applications such as aerospace, pharmaceutical processing, and semiconductor manufacturing due to its superior purity, high chemical resistance, and excellent dielectric properties. Reprocessed Teflon finds common use in non-critical industrial components like gaskets, seals, and linings where cost efficiency outweighs the need for high performance. Both types serve specific sectors, with virgin Teflon preferred for demanding environments and reprocessed Teflon favored for cost-sensitive, less rigorous applications.

Choosing the Right Teflon Grade for Your Needs

Virgin Teflon, made from pure, high-quality PTFE resin, offers superior chemical resistance, non-stick properties, and durability ideal for critical applications in aerospace and medical industries. Reprocessed Teflon, derived from recycled or scrap materials, provides a cost-effective alternative with slightly reduced performance, suitable for less demanding uses like general manufacturing or household products. Selecting the right Teflon grade depends on balancing performance requirements, budget constraints, and environmental considerations to ensure optimal functionality and longevity.

Virgin Teflon vs Reprocessed Teflon Infographic

materialdif.com

materialdif.com