Teflon coating provides a thin, non-stick layer directly applied to surfaces, enhancing durability and resistance to stains and chemicals. Teflon laminate involves bonding a Teflon film onto a substrate, offering greater protection against abrasion and heat. While coating allows for more flexibility on intricate shapes, lamination delivers superior longevity in high-wear applications.

Table of Comparison

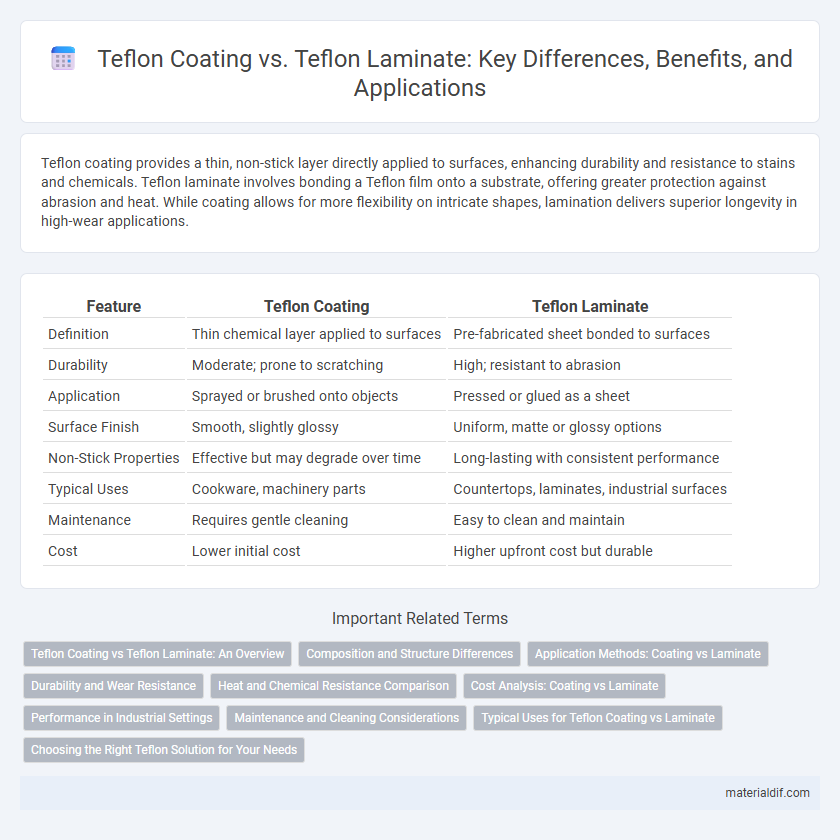

| Feature | Teflon Coating | Teflon Laminate |

|---|---|---|

| Definition | Thin chemical layer applied to surfaces | Pre-fabricated sheet bonded to surfaces |

| Durability | Moderate; prone to scratching | High; resistant to abrasion |

| Application | Sprayed or brushed onto objects | Pressed or glued as a sheet |

| Surface Finish | Smooth, slightly glossy | Uniform, matte or glossy options |

| Non-Stick Properties | Effective but may degrade over time | Long-lasting with consistent performance |

| Typical Uses | Cookware, machinery parts | Countertops, laminates, industrial surfaces |

| Maintenance | Requires gentle cleaning | Easy to clean and maintain |

| Cost | Lower initial cost | Higher upfront cost but durable |

Teflon Coating vs Teflon Laminate: An Overview

Teflon coating involves applying a thin layer of polytetrafluoroethylene (PTFE) onto surfaces to create a non-stick, heat-resistant barrier, ideal for cookware and industrial applications. Teflon laminate consists of PTFE bonded between layers of fabric or film, offering enhanced durability, chemical resistance, and electrical insulation for surfaces exposed to high stress. Choosing between Teflon coating and Teflon laminate depends on the required thickness, wear resistance, and specific functional needs in manufacturing or household use.

Composition and Structure Differences

Teflon coating consists of a thin, non-stick layer of polytetrafluoroethylene (PTFE) applied directly to a surface, providing a smooth, chemically resistant finish ideal for cookware and industrial applications. In contrast, Teflon laminate is a composite material where PTFE is bonded between layers of fabric or other substrates, resulting in a flexible, durable sheet used for gaskets, seals, and insulation. The main structural difference lies in the coating's surface attachment versus the laminate's layered construction, which enhances mechanical strength and thermal stability.

Application Methods: Coating vs Laminate

Teflon coating involves applying a thin, non-stick PTFE layer directly onto surfaces through processes like spraying or dipping, ensuring uniform coverage and excellent adhesion. Teflon laminate consists of bonding PTFE films onto substrates using heat and pressure, creating a thicker, durable layer ideal for high-wear applications. The coating method allows for more flexibility on complex shapes, while laminates provide enhanced mechanical strength and corrosion resistance.

Durability and Wear Resistance

Teflon coating offers excellent wear resistance with a smooth, non-stick surface that reduces friction and prevents material buildup, making it ideal for applications requiring frequent cleaning and low adhesion. In contrast, Teflon laminate provides superior durability by combining a Teflon film with a composite backing, enhancing resistance to abrasion, impact, and chemical exposure in harsh industrial environments. While Teflon coatings excel in lightweight, flexible applications, Teflon laminates deliver extended lifespan and robustness in demanding conditions.

Heat and Chemical Resistance Comparison

Teflon coating offers exceptional chemical resistance and can withstand temperatures up to 260degC (500degF), making it ideal for non-stick cookware and industrial applications exposed to moderate heat. Teflon laminate, consisting of multiple layers including Teflon, provides enhanced durability and superior chemical resistance, with temperature tolerances similar to coatings but improved structural integrity under continuous thermal stress. Both materials resist corrosive chemicals effectively, but Teflon laminate is preferred in environments requiring prolonged exposure to harsh chemicals and fluctuating high temperatures.

Cost Analysis: Coating vs Laminate

Teflon coating typically offers a more cost-effective solution compared to Teflon laminate due to its lower application expenses and minimal material usage. While Teflon laminate involves higher upfront costs from complex manufacturing and thicker material layers, it provides enhanced durability and longer lifespan, potentially reducing replacement frequency. Businesses should evaluate initial investment against maintenance and longevity when choosing between Teflon coating and laminate for optimal cost-efficiency.

Performance in Industrial Settings

Teflon coating offers superior non-stick and chemical resistance properties, making it ideal for machinery components exposed to abrasive materials and corrosive substances in industrial settings. Teflon laminate provides enhanced durability and thickness, which improves resistance to mechanical wear and impact, extending the lifespan of conveyor belts and industrial panels. Performance-wise, the choice between coating and laminate depends on the specific application needs, with coating excelling in surface protection and laminate in structural reinforcement.

Maintenance and Cleaning Considerations

Teflon coating offers a smooth, non-stick surface that requires minimal cleaning effort and resists stains, making maintenance straightforward with gentle wiping and occasional mild detergents. Teflon laminate, often used in countertops and furniture, demands more attention to prevent scratches and surface wear, necessitating gentle cleaning agents and avoidance of abrasive materials to preserve its protective layer. Both materials benefit from routine care to maintain their durability and appearance, but the coating is generally easier to maintain compared to laminate surfaces.

Typical Uses for Teflon Coating vs Laminate

Teflon coating is commonly used for non-stick cookware, industrial machinery, and electronic components due to its low friction and chemical resistance. Teflon laminate finds typical applications in gaskets, seals, and electrical insulation where durability and thermal stability are critical. Both materials leverage polytetrafluoroethylene (PTFE), but coatings provide surface protection while laminates offer structural reinforcement in high-performance environments.

Choosing the Right Teflon Solution for Your Needs

Teflon coating involves applying a thin, non-stick polymer layer directly onto surfaces to enhance durability and reduce friction, ideal for cookware and industrial equipment requiring smooth, easy-to-clean finishes. Teflon laminate, meanwhile, integrates a Teflon film between layers for added protection and chemical resistance, suited for applications needing strong thermal insulation or flexible, corrosion-resistant barriers. Evaluating factors such as intended use, environmental exposure, and mechanical stress helps determine whether Teflon coating's direct adhesion or laminate's multi-layered structure best meets specific performance and longevity requirements.

Teflon Coating vs Teflon Laminate Infographic

materialdif.com

materialdif.com