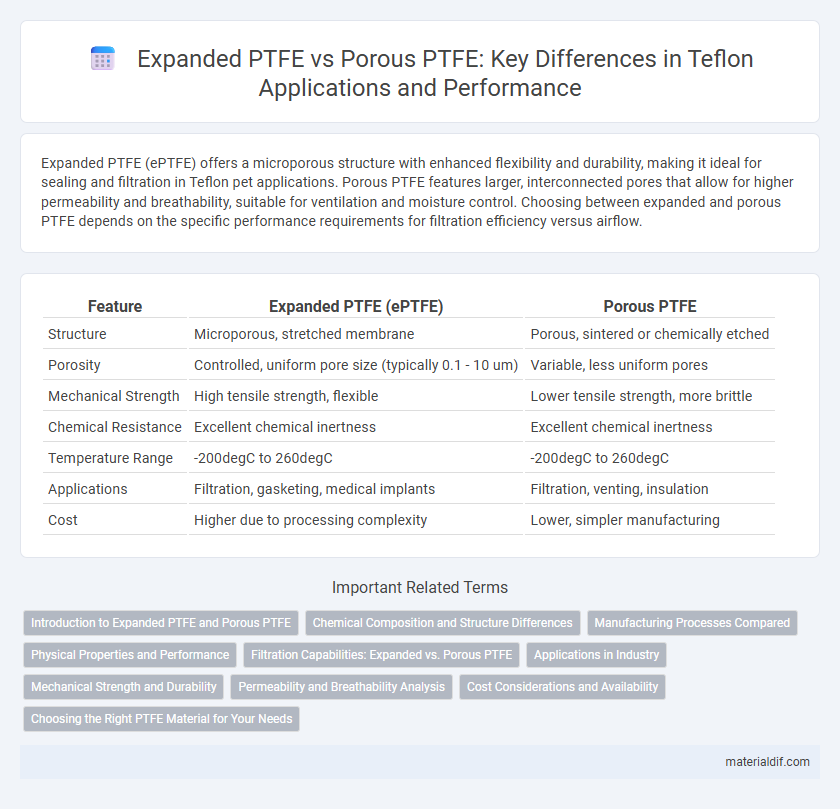

Expanded PTFE (ePTFE) offers a microporous structure with enhanced flexibility and durability, making it ideal for sealing and filtration in Teflon pet applications. Porous PTFE features larger, interconnected pores that allow for higher permeability and breathability, suitable for ventilation and moisture control. Choosing between expanded and porous PTFE depends on the specific performance requirements for filtration efficiency versus airflow.

Table of Comparison

| Feature | Expanded PTFE (ePTFE) | Porous PTFE |

|---|---|---|

| Structure | Microporous, stretched membrane | Porous, sintered or chemically etched |

| Porosity | Controlled, uniform pore size (typically 0.1 - 10 um) | Variable, less uniform pores |

| Mechanical Strength | High tensile strength, flexible | Lower tensile strength, more brittle |

| Chemical Resistance | Excellent chemical inertness | Excellent chemical inertness |

| Temperature Range | -200degC to 260degC | -200degC to 260degC |

| Applications | Filtration, gasketing, medical implants | Filtration, venting, insulation |

| Cost | Higher due to processing complexity | Lower, simpler manufacturing |

Introduction to Expanded PTFE and Porous PTFE

Expanded PTFE (ePTFE) is created by mechanically stretching PTFE, resulting in a microporous structure that combines high strength with excellent chemical resistance and breathability. Porous PTFE, formed by sintering or other processes, features interconnected pores that enhance filtration capabilities and fluid permeability while maintaining PTFE's inherent non-reactive properties. Both materials are essential in applications requiring chemical inertness and precise filtration, with ePTFE favored for flexibility and durability and porous PTFE chosen for controlled porosity and filtration efficiency.

Chemical Composition and Structure Differences

Expanded PTFE (ePTFE) features a microporous structure created by mechanically stretching PTFE, increasing its surface area and porosity without altering the chemical composition of polytetrafluoroethylene. Porous PTFE, on the other hand, is produced through sintering or other methods that create interconnected pores while maintaining the same chemical backbone. Both materials consist of PTFE's carbon-fluorine bonds, but their distinct pore sizes and structures influence properties such as permeability and mechanical strength.

Manufacturing Processes Compared

Expanded PTFE (ePTFE) is produced by mechanically stretching PTFE under controlled conditions, creating a microporous structure with enhanced tensile strength and flexibility, ideal for applications requiring durability and breathability. Porous PTFE is manufactured by incorporating a pore-forming agent during the PTFE sintering process or by chemically etching, resulting in a network of interconnected pores tailored for filtration and diffusion purposes. The mechanical expansion method in ePTFE offers precise control over pore size and distribution, whereas porous PTFE relies on additive or etching techniques to achieve desired porosity without altering the polymer's overall structural integrity.

Physical Properties and Performance

Expanded PTFE (ePTFE) exhibits a microporous structure with high tensile strength, excellent flexibility, and superior chemical resistance, making it ideal for applications requiring durability and resilience under mechanical stress. Porous PTFE, characterized by its larger pore size and higher porosity, offers enhanced breathability and fluid permeability but generally has lower mechanical strength compared to ePTFE. The distinct physical properties of ePTFE enable better performance in sealing and filtration applications, while porous PTFE excels in breathable membranes and controlled permeability scenarios.

Filtration Capabilities: Expanded vs. Porous PTFE

Expanded PTFE features a micro-porous structure with elongated fibrils and nodes, providing superior filtration by trapping particles as small as 0.1 microns while maintaining high breathability. Porous PTFE contains larger, more irregular pores, allowing for faster flow rates but less effective filtration of ultra-fine particles. The choice between expanded and porous PTFE hinges on specific filtration needs, where expanded PTFE excels in precision filtration applications such as medical and air purification filters.

Applications in Industry

Expanded PTFE offers superior tensile strength and flexibility, making it ideal for gaskets, seals, and filtration membranes used in chemical processing and automotive industries. Porous PTFE's high porosity and chemical inertness suit applications in breathable fabrics, medical implants, and gas diffusion layers in fuel cells. Both materials serve diverse industrial needs, with expanded PTFE excelling in mechanical performance and porous PTFE in filtration and permeability.

Mechanical Strength and Durability

Expanded PTFE (ePTFE) exhibits superior mechanical strength due to its microporous structure formed by stretching, which enhances tensile strength and flexibility. Porous PTFE, while offering high permeability, typically has lower mechanical durability because its interconnected pores reduce material integrity under stress. The enhanced durability of ePTFE makes it ideal for applications requiring resilience against mechanical wear and tear.

Permeability and Breathability Analysis

Expanded PTFE exhibits a microporous structure with interconnected pores, providing superior permeability and breathability compared to porous PTFE, which contains larger, less uniform pores. The nanoscale pores in expanded PTFE facilitate efficient vapor transmission while blocking liquid water, enhancing moisture management in applications like outdoor apparel and medical devices. Porous PTFE tends to have lower breathability due to its heterogeneous pore distribution, resulting in reduced air and vapor permeability performance.

Cost Considerations and Availability

Expanded PTFE (ePTFE) typically incurs higher costs due to its specialized manufacturing process involving mechanical stretching, which enhances its strength and microporous structure, whereas porous PTFE is generally less expensive but offers lower mechanical durability. Availability varies with ePTFE being less common and often sourced from specialized suppliers, while porous PTFE is more widely produced and accessible in bulk for standard applications. Cost considerations weigh heavily for large-scale industrial use, where the superior performance of ePTFE must justify its premium price and limited supply.

Choosing the Right PTFE Material for Your Needs

Expanded PTFE (ePTFE) offers a microporous structure with high tensile strength and excellent chemical resistance, making it ideal for filtration and gasketing applications requiring durability and flexibility. Porous PTFE features larger pores that provide superior breathability and fluid permeability, suited for applications such as venting and membrane technology. Selecting the right PTFE material depends on your need for strength, permeability, and chemical stability to ensure optimal performance and longevity.

Expanded PTFE vs Porous PTFE Infographic

materialdif.com

materialdif.com