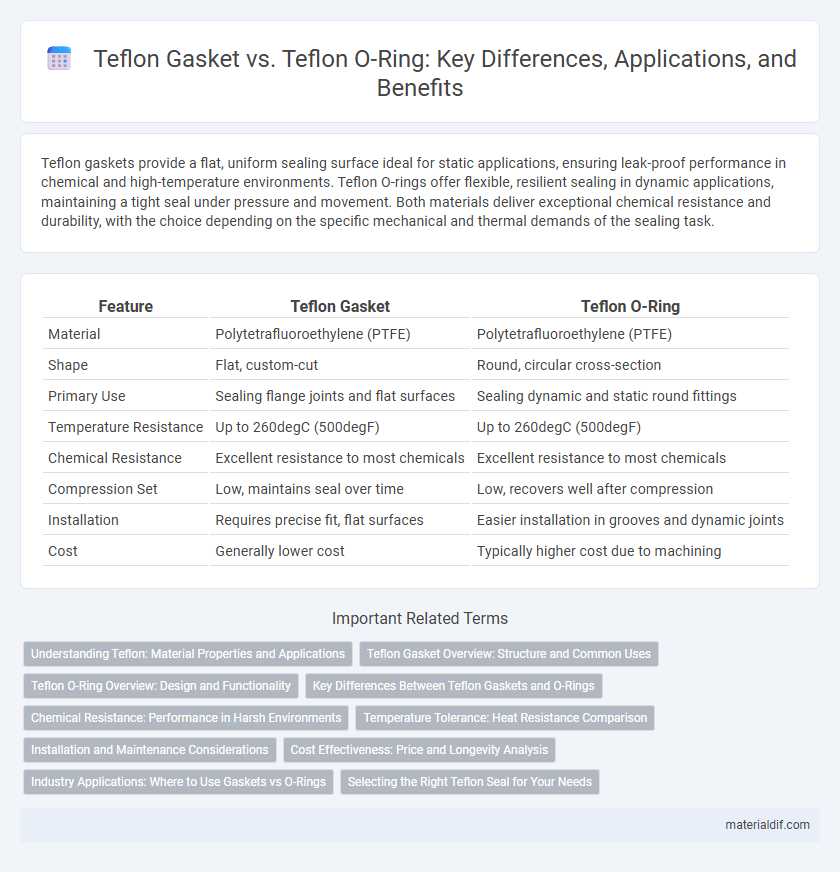

Teflon gaskets provide a flat, uniform sealing surface ideal for static applications, ensuring leak-proof performance in chemical and high-temperature environments. Teflon O-rings offer flexible, resilient sealing in dynamic applications, maintaining a tight seal under pressure and movement. Both materials deliver exceptional chemical resistance and durability, with the choice depending on the specific mechanical and thermal demands of the sealing task.

Table of Comparison

| Feature | Teflon Gasket | Teflon O-Ring |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Polytetrafluoroethylene (PTFE) |

| Shape | Flat, custom-cut | Round, circular cross-section |

| Primary Use | Sealing flange joints and flat surfaces | Sealing dynamic and static round fittings |

| Temperature Resistance | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Chemical Resistance | Excellent resistance to most chemicals | Excellent resistance to most chemicals |

| Compression Set | Low, maintains seal over time | Low, recovers well after compression |

| Installation | Requires precise fit, flat surfaces | Easier installation in grooves and dynamic joints |

| Cost | Generally lower cost | Typically higher cost due to machining |

Understanding Teflon: Material Properties and Applications

Teflon gaskets and Teflon O-rings both utilize polytetrafluoroethylene's exceptional chemical resistance, high-temperature tolerance up to 260degC, and low friction coefficient for sealing applications. Teflon gaskets typically provide flat, customizable sealing surfaces ideal for flange connections, while Teflon O-rings offer flexible, round profiles suited for dynamic or static sealing in confined spaces. Both components excel in industries such as chemical processing, food production, and pharmaceuticals due to Teflon's inertness, non-stick properties, and durability under aggressive conditions.

Teflon Gasket Overview: Structure and Common Uses

Teflon gaskets are engineered from polytetrafluoroethylene (PTFE), known for exceptional chemical resistance and high temperature tolerance, making them ideal for sealing applications in aggressive environments. Their flat, sheet-like structure allows them to create tight seals between flanged surfaces, commonly used in chemical processing, pharmaceuticals, and food industries. These gaskets effectively prevent leaks in static sealing applications where flexibility and durability are critical under extreme pressure and corrosive conditions.

Teflon O-Ring Overview: Design and Functionality

Teflon O-rings are precision-engineered sealing components made from polytetrafluoroethylene (PTFE), known for their exceptional chemical resistance and low friction properties. Their design features a circular cross-section that ensures a tight seal in high-temperature and corrosive environments, outperforming traditional elastomeric gaskets. These O-rings maintain integrity under extreme pressure while providing excellent dimensional stability, making them ideal for applications in chemical processing, pharmaceuticals, and aerospace industries.

Key Differences Between Teflon Gaskets and O-Rings

Teflon gaskets are flat sealing components designed to fill irregular spaces between two surfaces, providing leak-proof seals in flange connections, while Teflon O-rings are circular, torus-shaped seals primarily used in dynamic and static applications to prevent fluid leakage in machinery. The key differences lie in their shapes, applications, and sealing mechanisms; gaskets accommodate uneven surfaces and compress to fill gaps, whereas O-rings rely on compression within a groove to create a tight seal. Material properties such as chemical resistance and temperature tolerance apply to both, but the choice depends on specific engineering requirements including pressure, movement, and surface configuration.

Chemical Resistance: Performance in Harsh Environments

Teflon gaskets offer superior chemical resistance due to their thicker cross-sections, making them ideal for sealing applications exposed to aggressive acids, solvents, and high temperatures. Teflon O-rings, while providing excellent chemical inertness, are better suited for dynamic sealing with moderate chemical exposure and flexibility requirements in harsh environments. Both materials excel in resisting corrosion and degradation, but selection depends on the specific mechanical stresses and chemical concentrations encountered.

Temperature Tolerance: Heat Resistance Comparison

Teflon gaskets typically withstand temperatures up to 260degC (500degF), making them ideal for high-heat industrial applications, while Teflon O-rings generally tolerate slightly lower temperatures, up to around 205degC (400degF). The superior heat resistance of Teflon gaskets results from their thicker, more solid construction, enabling better sealing performance under extreme thermal conditions. In contrast, Teflon O-rings offer flexible sealing solutions but may deform or degrade faster at elevated temperatures, limiting their use in high-heat environments.

Installation and Maintenance Considerations

Teflon gaskets typically require precise alignment and uniform compression during installation to ensure optimal sealing performance, whereas Teflon O-rings offer easier installation with their flexible, self-seating design. Maintenance of Teflon gaskets involves regular inspection for wear and potential deformation under high pressure, while Teflon O-rings demand monitoring for signs of extrusion or compression set over time. Both materials benefit from chemical resistance and temperature tolerance, but correct installation technique is crucial to prevent leaks and extend service life.

Cost Effectiveness: Price and Longevity Analysis

Teflon gaskets generally offer a higher upfront cost compared to Teflon O-rings but provide superior durability and chemical resistance, resulting in longer service life and lower replacement frequency. Teflon O-rings are more cost-effective for applications requiring moderate sealing performance and easier installation, making them ideal for budget-sensitive projects. Evaluating total lifecycle expenses, Teflon gaskets often yield better cost efficiency in harsh environments, while Teflon O-rings save costs in less demanding sealing applications.

Industry Applications: Where to Use Gaskets vs O-Rings

Teflon gaskets are ideal for sealing flanges and large surface areas in chemical processing, food production, and pharmaceutical industries due to their excellent chemical resistance and ability to withstand high temperatures. Teflon O-rings are preferred in dynamic applications such as hydraulic systems, pumps, and valves where flexibility and tight sealing under pressure are critical. Choosing between Teflon gaskets and O-rings depends on the specific industry requirements, including pressure conditions, temperature ranges, and chemical exposure.

Selecting the Right Teflon Seal for Your Needs

Teflon gaskets provide a reliable, flush seal ideal for flange connections and applications requiring extensive surface contact, while Teflon O-rings excel in dynamic sealing scenarios with axial or radial movements. Selecting the right Teflon seal depends on pressure ratings, temperature resistance up to 260degC, and chemical compatibility, with gaskets offering broader surface area sealing and O-rings enabling easier installation in confined spaces. Evaluate operating conditions such as media type, pressure range up to 20,000 psi, and mechanical stress to determine whether the machinability and deformation tolerance of gaskets or the elasticity and compact form factor of O-rings best suit your sealing requirements.

Teflon Gasket vs Teflon O-Ring Infographic

materialdif.com

materialdif.com