Teflon spray provides a thin, uniform coating ideal for smaller, intricate items requiring precise protection against friction and corrosion, while Teflon powder coating offers a thicker, more durable layer suited for heavy-duty applications and larger surfaces. The spray application allows for easier touch-ups and detailed coverage, whereas powder coating requires curing in an oven, resulting in a tougher, more resilient finish. Choosing between Teflon spray and powder coating depends on the specific requirements of surface size, durability, and environmental exposure.

Table of Comparison

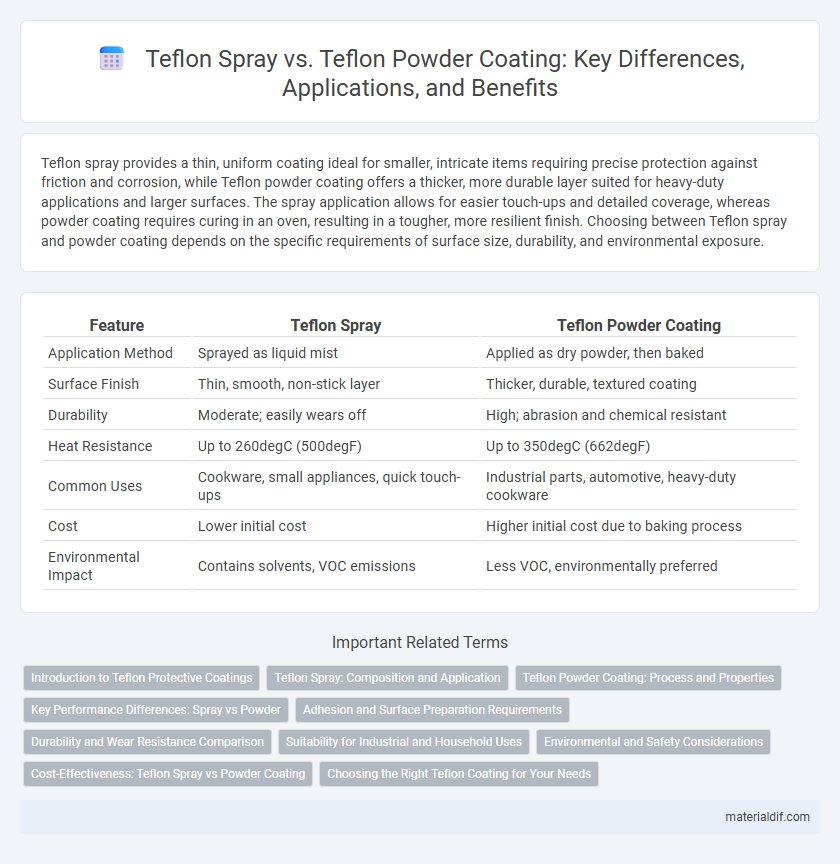

| Feature | Teflon Spray | Teflon Powder Coating |

|---|---|---|

| Application Method | Sprayed as liquid mist | Applied as dry powder, then baked |

| Surface Finish | Thin, smooth, non-stick layer | Thicker, durable, textured coating |

| Durability | Moderate; easily wears off | High; abrasion and chemical resistant |

| Heat Resistance | Up to 260degC (500degF) | Up to 350degC (662degF) |

| Common Uses | Cookware, small appliances, quick touch-ups | Industrial parts, automotive, heavy-duty cookware |

| Cost | Lower initial cost | Higher initial cost due to baking process |

| Environmental Impact | Contains solvents, VOC emissions | Less VOC, environmentally preferred |

Introduction to Teflon Protective Coatings

Teflon protective coatings include both spray and powder coating methods, each offering unique advantages in corrosion resistance and non-stick properties. Teflon spray provides a thin, even layer ideal for intricate surfaces and touch-ups, while Teflon powder coating delivers a thicker, more durable finish suited for heavy-duty industrial applications. These coatings enhance chemical resistance and reduce friction, making them essential in automotive, aerospace, and cookware industries.

Teflon Spray: Composition and Application

Teflon spray is composed of polytetrafluoroethylene (PTFE) particles suspended in a solvent base, allowing for easy application on various surfaces. The spray form enables a thin, uniform layer that creates a non-stick, low-friction coating ideal for automotive parts, cookware, and industrial equipment. Its application process involves spraying onto a clean substrate, followed by curing to bond the PTFE film, enhancing surface durability and resistance to heat and chemicals.

Teflon Powder Coating: Process and Properties

Teflon powder coating involves electrostatically applying finely ground Teflon particles onto a surface, followed by heating to melt and fuse the particles into a continuous, uniform film. This process creates a durable, non-stick, chemically resistant, and low-friction surface ideal for industrial and cookware applications. The resulting coating exhibits excellent adhesion, high-temperature tolerance up to 260degC (500degF), and exceptional resistance to corrosion and wear.

Key Performance Differences: Spray vs Powder

Teflon spray offers excellent ease of application and quick drying times, making it ideal for small or intricate surfaces requiring a thin, uniform non-stick layer. Teflon powder coating, by contrast, provides superior durability, abrasion resistance, and heat tolerance due to its thicker, more robust finish achieved through curing processes. Spray coatings are best for touch-ups and light-duty applications, while powder coatings excel in industrial settings demanding long-lasting, wear-resistant surfaces.

Adhesion and Surface Preparation Requirements

Teflon spray requires minimal surface preparation, making it suitable for quick applications on smooth, clean surfaces, but its adhesion is generally weaker compared to powder coatings. Teflon powder coating demands thorough surface treatment, including sandblasting or chemical etching, to ensure strong adhesion and durability. The enhanced bonding of powder coating provides superior resistance to wear and corrosion, making it ideal for industrial and high-performance applications.

Durability and Wear Resistance Comparison

Teflon spray provides a thin, flexible protective layer ideal for reducing friction and preventing corrosion on light-duty surfaces, but it wears off more quickly under heavy use. Teflon powder coating forms a thicker, more robust finish through a curing process, delivering superior durability and excellent wear resistance suitable for industrial applications. The powder coating's cross-linked polymer structure enhances abrasion resistance and longevity, making it a preferred choice for high-stress environments.

Suitability for Industrial and Household Uses

Teflon spray offers a versatile, easy-to-apply solution ideal for household uses such as cookware and small appliances due to its quick drying and non-stick properties. Teflon powder coating provides a durable, industrial-grade finish that withstands high temperatures, chemical exposure, and mechanical wear, making it suitable for heavy machinery, automotive parts, and manufacturing equipment. Selecting between Teflon spray and powder coating depends on the required durability, application complexity, and specific environmental resistance needed for industrial or household applications.

Environmental and Safety Considerations

Teflon spray typically contains volatile organic compounds (VOCs) that may contribute to indoor air pollution and require proper ventilation during application. In contrast, Teflon powder coating is a solvent-free process that minimizes VOC emissions and reduces environmental impact. Both methods require careful handling to avoid inhalation of particles or fumes, but powder coating generally offers enhanced safety and lower environmental risks.

Cost-Effectiveness: Teflon Spray vs Powder Coating

Teflon spray typically offers a more cost-effective solution upfront due to lower application equipment and labor requirements compared to Teflon powder coating. Powder coating, while initially more expensive, delivers superior durability and longer lifespan, potentially reducing replacement and maintenance costs over time. Evaluating total cost of ownership reveals that spray is advantageous for short-term projects, whereas powder coating optimizes cost-effectiveness for long-term industrial applications.

Choosing the Right Teflon Coating for Your Needs

Teflon spray offers a thin, even layer ideal for lightweight applications and surfaces requiring a smooth, non-stick finish. Teflon powder coating provides a thicker, more durable protection suited for heavy-duty industrial uses, enhancing chemical resistance and abrasion protection. Selecting the right Teflon coating depends on the required durability, environmental exposure, and surface type to ensure optimal performance and longevity.

Teflon Spray vs Teflon Powder Coating Infographic

materialdif.com

materialdif.com