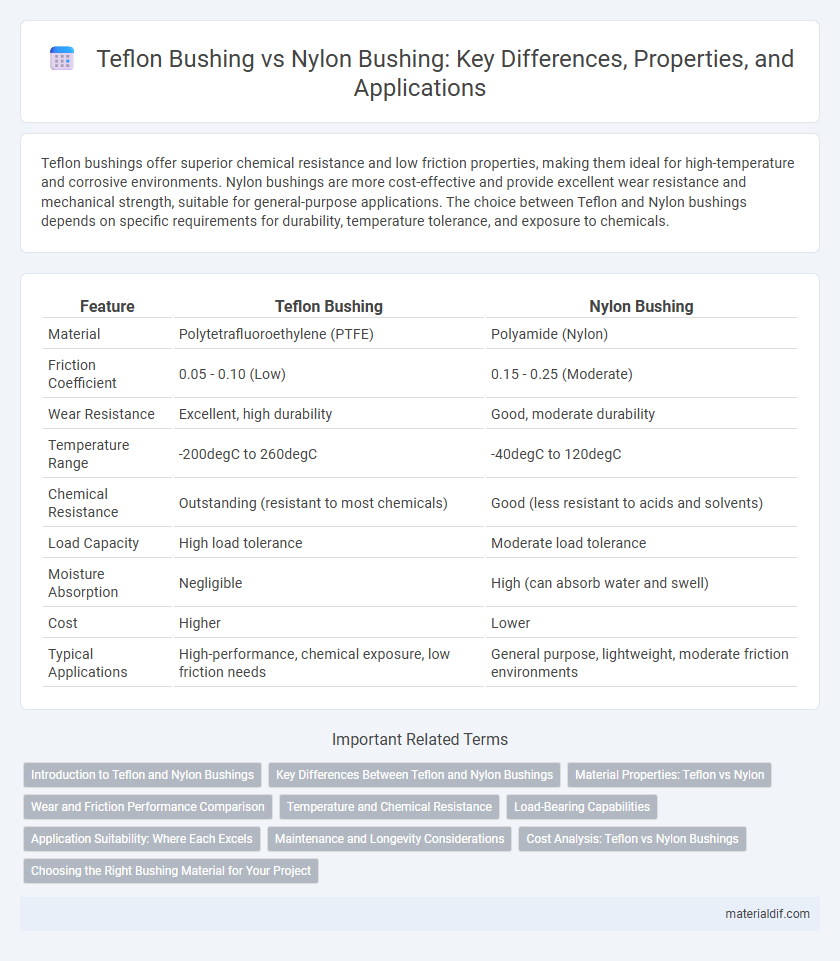

Teflon bushings offer superior chemical resistance and low friction properties, making them ideal for high-temperature and corrosive environments. Nylon bushings are more cost-effective and provide excellent wear resistance and mechanical strength, suitable for general-purpose applications. The choice between Teflon and Nylon bushings depends on specific requirements for durability, temperature tolerance, and exposure to chemicals.

Table of Comparison

| Feature | Teflon Bushing | Nylon Bushing |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Polyamide (Nylon) |

| Friction Coefficient | 0.05 - 0.10 (Low) | 0.15 - 0.25 (Moderate) |

| Wear Resistance | Excellent, high durability | Good, moderate durability |

| Temperature Range | -200degC to 260degC | -40degC to 120degC |

| Chemical Resistance | Outstanding (resistant to most chemicals) | Good (less resistant to acids and solvents) |

| Load Capacity | High load tolerance | Moderate load tolerance |

| Moisture Absorption | Negligible | High (can absorb water and swell) |

| Cost | Higher | Lower |

| Typical Applications | High-performance, chemical exposure, low friction needs | General purpose, lightweight, moderate friction environments |

Introduction to Teflon and Nylon Bushings

Teflon bushings, made from polytetrafluoroethylene (PTFE), offer exceptional chemical resistance, low friction, and high-temperature tolerance, making them ideal for demanding industrial applications. Nylon bushings provide good wear resistance, toughness, and low moisture absorption, suitable for moderate temperature and load conditions. Understanding the material properties of Teflon and Nylon bushings is essential for selecting the right component based on environmental factors and mechanical requirements.

Key Differences Between Teflon and Nylon Bushings

Teflon bushings exhibit superior chemical resistance and low friction properties compared to nylon bushings, making them ideal for applications requiring smooth motion and durability in harsh environments. Nylon bushings provide greater impact resistance and higher load-bearing capacity but tend to absorb moisture, which can affect their dimensional stability. The choice between Teflon and nylon bushings depends on specific factors such as operating temperature, exposure to chemicals, and mechanical load requirements.

Material Properties: Teflon vs Nylon

Teflon bushings exhibit exceptional chemical resistance, low friction coefficient, and high-temperature tolerance up to 260degC, making them ideal for demanding industrial applications. Nylon bushings offer superior strength, abrasion resistance, and moisture absorption properties, but their temperature tolerance is limited to around 120degC. The choice between Teflon and Nylon hinges on the specific requirements for thermal stability, friction reduction, and environmental exposure in the intended application.

Wear and Friction Performance Comparison

Teflon bushings exhibit significantly lower friction coefficients compared to nylon bushings, resulting in smoother operation and enhanced wear resistance under high-load conditions. Their self-lubricating properties reduce the need for external lubrication, extending service life in abrasive environments. Nylon bushings, while durable, tend to experience higher wear rates and increased friction, particularly in applications involving continuous sliding or high temperatures.

Temperature and Chemical Resistance

Teflon bushings exhibit superior temperature resistance, withstanding continuous use up to 260degC (500degF), compared to nylon bushings that typically tolerate temperatures only up to 120degC (248degF). Chemically, Teflon offers exceptional resistance to a wide range of aggressive solvents, acids, and bases, making it ideal for harsh chemical environments, whereas nylon can degrade when exposed to strong acids or prolonged chemical exposure. The enhanced thermal stability and chemical inertness of Teflon bushings ensure longer service life and reliability in demanding industrial applications.

Load-Bearing Capabilities

Teflon bushings offer superior load-bearing capabilities compared to nylon bushings due to their low coefficient of friction and high resistance to deformation under pressure. The self-lubricating properties of Teflon reduce wear and extend the lifespan in heavy-load applications. Nylon bushings generally perform well under moderate loads but can experience creep and deformation when subjected to continuous high pressure.

Application Suitability: Where Each Excels

Teflon bushings excel in applications requiring high chemical resistance, low friction, and wide temperature tolerance, making them ideal for corrosive environments and high-speed machinery. Nylon bushings are better suited for impact resistance, load-bearing, and quieter operation, commonly used in automotive and industrial equipment with moderate temperature conditions. Choosing between Teflon and nylon depends on the specific demands of the application, such as exposure to chemicals, temperature range, and mechanical stress.

Maintenance and Longevity Considerations

Teflon bushings require minimal maintenance due to their self-lubricating properties, which reduce wear and extend service life compared to nylon bushings that may need periodic lubrication to prevent friction damage. Teflon's high chemical resistance and low coefficient of friction make it ideal for harsh environments, ensuring superior longevity in applications prone to exposure to chemicals or high temperatures. Nylon bushings, while cost-effective and durable under moderate conditions, typically exhibit faster wear rates and require more frequent inspection and replacement in demanding maintenance schedules.

Cost Analysis: Teflon vs Nylon Bushings

Teflon bushings generally have a higher upfront cost compared to nylon bushings due to their superior chemical resistance and low friction properties. Nylon bushings are more cost-effective for applications with moderate wear and lower temperature requirements but may require more frequent replacement, increasing long-term expenses. Evaluating the total cost of ownership, including maintenance and replacement intervals, is essential for determining the value of Teflon versus nylon bushings in specific industrial environments.

Choosing the Right Bushing Material for Your Project

Teflon bushings offer exceptional chemical resistance and low friction, making them ideal for applications involving high temperatures or corrosive environments. Nylon bushings provide superior impact resistance and dimensional stability, suited for load-bearing projects with moderate wear conditions. Selecting the right bushing material depends on factors like operating temperature, chemical exposure, and mechanical stress to ensure optimal performance and longevity.

Teflon Bushing vs Nylon Bushing Infographic

materialdif.com

materialdif.com