Teflon jacketed components offer a durable outer layer that protects inner materials from harsh chemicals and extreme temperatures while maintaining flexibility. Teflon encapsulated parts provide a seamless, fully enclosed barrier that ensures superior resistance to corrosion and contamination. Choosing between jacketed and encapsulated Teflon depends on the specific requirements for protection, flexibility, and environmental exposure in industrial applications.

Table of Comparison

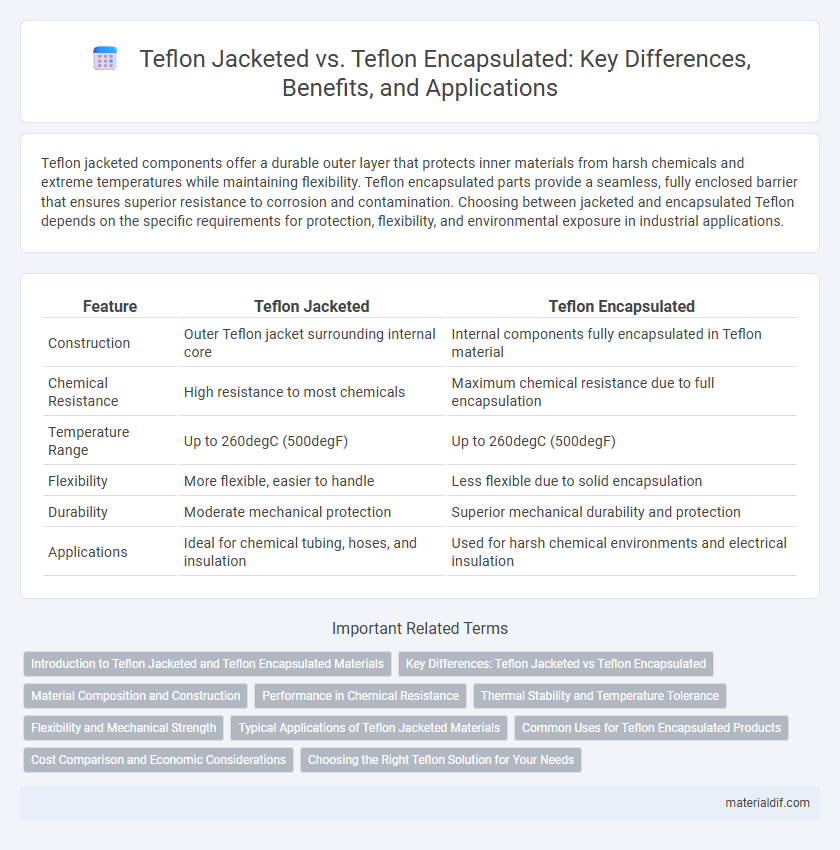

| Feature | Teflon Jacketed | Teflon Encapsulated |

|---|---|---|

| Construction | Outer Teflon jacket surrounding internal core | Internal components fully encapsulated in Teflon material |

| Chemical Resistance | High resistance to most chemicals | Maximum chemical resistance due to full encapsulation |

| Temperature Range | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Flexibility | More flexible, easier to handle | Less flexible due to solid encapsulation |

| Durability | Moderate mechanical protection | Superior mechanical durability and protection |

| Applications | Ideal for chemical tubing, hoses, and insulation | Used for harsh chemical environments and electrical insulation |

Introduction to Teflon Jacketed and Teflon Encapsulated Materials

Teflon jacketed materials feature a protective outer layer of polytetrafluoroethylene (PTFE) that offers excellent chemical resistance and low friction surface properties, making them ideal for insulation and protective coatings in harsh industrial environments. Teflon encapsulated materials involve embedding a core material within a continuous PTFE barrier, providing superior sealing and contamination resistance in applications requiring high purity and durability. Both materials leverage Teflon's inherent non-stick, thermal stability, and corrosion resistance but differ in construction and specific functional advantages.

Key Differences: Teflon Jacketed vs Teflon Encapsulated

Teflon jacketed components feature an outer layer of Teflon that provides chemical resistance and thermal insulation while maintaining flexibility and ease of inspection. In contrast, Teflon encapsulated products have Teflon fully enveloping the core material, offering enhanced protection against corrosion, contamination, and extreme environmental conditions. The primary difference lies in the level of coverage, with jacketed designs allowing partial exposure of the base material versus encapsulated designs providing complete sealing.

Material Composition and Construction

Teflon jacketed products feature a protective outer layer of PTFE (polytetrafluoroethylene) wrapped around a substrate, offering flexibility and chemical resistance. Teflon encapsulated items involve PTFE fully encasing the core material, providing enhanced durability, superior sealing, and increased resistance to contamination. The construction difference impacts performance in harsh chemical environments, with encapsulated designs typically favored for high-pressure sealing applications due to their robust integrity.

Performance in Chemical Resistance

Teflon jacketed products provide robust chemical resistance by offering an external protective layer that prevents contamination and degradation from aggressive chemicals. Teflon encapsulated components feature a complete sealing process, enhancing their resistance to harsh environments by eliminating exposure to underlying materials. Encapsulation typically surpasses jacketed designs in durability against reactive substances, ensuring longer service life in corrosive applications.

Thermal Stability and Temperature Tolerance

Teflon jacketed materials provide excellent thermal stability with temperature tolerance typically ranging from -200degC to 260degC, making them ideal for applications requiring consistent performance under extreme cold and moderate heat. Teflon encapsulated products enhance protection by fully enclosing the substrate, offering superior resistance to thermal degradation and chemical exposure, often maintaining integrity up to 270degC. The choice between Teflon jacketed and encapsulated coatings depends on the specific thermal demands and environmental conditions of the application.

Flexibility and Mechanical Strength

Teflon jacketed cables provide enhanced flexibility due to their outer Teflon layer, making them ideal for applications requiring frequent movement or bending. In contrast, Teflon encapsulated cables offer superior mechanical strength and chemical resistance by fully enveloping the internal components with Teflon, protecting them from harsh environments. Selecting between Teflon jacketed and encapsulated options depends on the balance needed between flexibility and mechanical durability.

Typical Applications of Teflon Jacketed Materials

Teflon jacketed materials are prominently used in chemical processing industries due to their excellent resistance to corrosive substances and high temperatures, making them ideal for lining pipes, tanks, and vessels. These materials provide reliable protection in applications involving aggressive chemicals, such as acids, solvents, and alkalis. Their durability and non-reactive properties ensure long-term containment and safety in pharmaceutical, food processing, and semiconductor manufacturing environments.

Common Uses for Teflon Encapsulated Products

Teflon encapsulated products are commonly used in chemical processing industries to provide superior chemical resistance and prevent contamination in highly corrosive environments. These products are ideal for lining pipes, valves, and pumps where complete isolation of metal parts from aggressive chemicals is essential. Their ability to withstand extreme temperatures and aggressive solvents makes them crucial in pharmaceuticals, food processing, and industrial manufacturing applications.

Cost Comparison and Economic Considerations

Teflon jacketed products typically offer a more cost-effective solution due to simpler manufacturing processes, resulting in lower initial expenses compared to Teflon encapsulated items. Teflon encapsulated materials provide enhanced durability and chemical resistance, often justifying higher upfront costs with longer service life and reduced maintenance. Evaluating total cost of ownership, including replacement frequency and operational efficiency, is essential for making informed economic decisions between the two options.

Choosing the Right Teflon Solution for Your Needs

Teflon jacketed components feature a thin, uniform layer of PTFE that provides excellent chemical resistance and flexibility for dynamic applications, while Teflon encapsulated items involve a thicker, fully surrounding PTFE layer offering superior durability and long-term protection in harsh environments. Selecting the right Teflon solution depends on factors such as exposure to aggressive chemicals, mechanical stress, temperature fluctuations, and the need for electrical insulation. For applications requiring high flexibility and moderate chemical exposure, Teflon jacketed solutions are preferred, whereas Teflon encapsulated products are ideal for demanding industrial uses needing maximum protection and longevity.

Teflon Jacketed vs Teflon Encapsulated Infographic

materialdif.com

materialdif.com