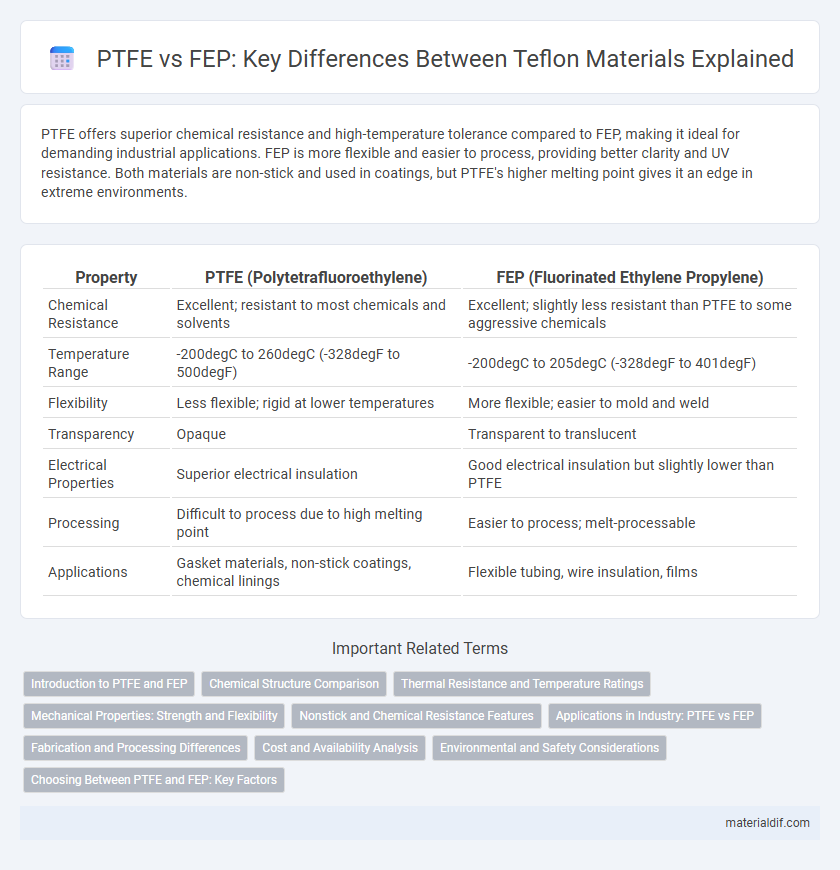

PTFE offers superior chemical resistance and high-temperature tolerance compared to FEP, making it ideal for demanding industrial applications. FEP is more flexible and easier to process, providing better clarity and UV resistance. Both materials are non-stick and used in coatings, but PTFE's higher melting point gives it an edge in extreme environments.

Table of Comparison

| Property | PTFE (Polytetrafluoroethylene) | FEP (Fluorinated Ethylene Propylene) |

|---|---|---|

| Chemical Resistance | Excellent; resistant to most chemicals and solvents | Excellent; slightly less resistant than PTFE to some aggressive chemicals |

| Temperature Range | -200degC to 260degC (-328degF to 500degF) | -200degC to 205degC (-328degF to 401degF) |

| Flexibility | Less flexible; rigid at lower temperatures | More flexible; easier to mold and weld |

| Transparency | Opaque | Transparent to translucent |

| Electrical Properties | Superior electrical insulation | Good electrical insulation but slightly lower than PTFE |

| Processing | Difficult to process due to high melting point | Easier to process; melt-processable |

| Applications | Gasket materials, non-stick coatings, chemical linings | Flexible tubing, wire insulation, films |

Introduction to PTFE and FEP

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer renowned for its exceptional chemical resistance, non-stick properties, and high-temperature tolerance, making it widely used in coatings, gaskets, and sealants. Fluorinated ethylene propylene (FEP) shares many characteristics with PTFE, including chemical inertness and temperature resistance, but offers improved transparency and melt-processability, facilitating easier fabrication into films and tubing. Both PTFE and FEP belong to the fluoropolymer family, with PTFE being more rigid and FEP more flexible, optimizing their applications across various industrial sectors.

Chemical Structure Comparison

PTFE (polytetrafluoroethylene) features a linear polymer chain composed solely of carbon and fluorine atoms, resulting in a highly stable and inert structure due to the strong carbon-fluorine bonds. FEP (fluorinated ethylene propylene) differs by incorporating hexafluoropropylene units into its polymer chain, introducing side branches that slightly alter its crystallinity and melting point. This structural variation in FEP provides enhanced flexibility and improved processability compared to the more rigid and crystalline PTFE.

Thermal Resistance and Temperature Ratings

PTFE (Polytetrafluoroethylene) exhibits superior thermal resistance with an operating temperature range from -200degC to 260degC, making it ideal for high-temperature applications. FEP (Fluorinated Ethylene Propylene) offers slightly lower thermal resistance, typically rated from -200degC to 205degC, but provides enhanced flexibility and easier processing compared to PTFE. The higher maximum temperature tolerance of PTFE ensures better performance in extreme heat environments, while FEP is preferred for applications requiring moderate heat resistance with improved mechanical properties.

Mechanical Properties: Strength and Flexibility

PTFE exhibits higher tensile strength and superior chemical resistance compared to FEP, making it ideal for demanding mechanical applications. FEP offers greater flexibility and improved impact resistance due to its lower melting point, which enhances its ability to withstand repeated bending and stress. The choice between PTFE and FEP depends on balancing strength requirements with the need for flexibility in specific operational environments.

Nonstick and Chemical Resistance Features

PTFE offers superior nonstick properties with a low coefficient of friction, making it ideal for applications requiring effortless release of materials. FEP, while maintaining excellent chemical resistance similar to PTFE, provides greater flexibility and transparency but slightly reduced nonstick performance. Both polymers resist aggressive chemicals, solvents, and acids, ensuring durability in harsh environments.

Applications in Industry: PTFE vs FEP

PTFE (Polytetrafluoroethylene) excels in chemical resistance and high-temperature stability, making it ideal for applications such as gasket manufacturing, chemical processing equipment, and non-stick coatings in cookware. FEP (Fluorinated Ethylene Propylene) offers superior flexibility and clarity, which suits it for use in electrical insulation, tubing for pharmaceutical and food industries, and transparent protective coatings. Both materials provide excellent non-reactive surfaces, but PTFE dominates heavy-duty industrial uses requiring extreme temperature resistance, while FEP is preferred where flexibility and transparency are critical.

Fabrication and Processing Differences

PTFE and FEP differ significantly in fabrication and processing methods due to their distinct molecular structures and melting properties. PTFE cannot be melt-processed and requires sintering and paste extrusion, making shaping more complex and time-consuming. In contrast, FEP melts at a lower temperature, allowing for conventional melt extrusion and injection molding, which simplifies processing and enables faster production cycles.

Cost and Availability Analysis

Polytetrafluoroethylene (PTFE) generally costs more than Fluorinated Ethylene Propylene (FEP) due to its higher melting point and superior chemical resistance, making it essential for demanding applications. FEP, while less expensive, offers easier processability and better availability in thin-film forms, supporting wider commercial use in industries like electrical insulation and chemical tubing. Market analysis shows PTFE's limited suppliers and longer lead times elevate its price, whereas FEP benefits from broader manufacturing sources, enhancing its accessibility and cost-effectiveness.

Environmental and Safety Considerations

PTFE and FEP both offer excellent chemical resistance and thermal stability, but FEP is more environmentally friendly due to its lower melting point, which reduces energy consumption during processing. FEP releases fewer toxic fumes when heated compared to PTFE, enhancing safety in manufacturing and application environments. PTFE's persistence in the environment raises concerns about long-term ecological impact, prompting industries to favor FEP for safer, more sustainable fluoropolymer use.

Choosing Between PTFE and FEP: Key Factors

PTFE offers superior chemical resistance and higher temperature tolerance up to 260degC, making it ideal for harsh industrial applications requiring durability and non-reactivity. FEP provides excellent electrical insulation and transparency with a lower melting point around 205degC, suitable for applications needing ease of processing and visual inspection. Selection depends on needed temperature resistance, chemical exposure, mechanical strength, and clarity requirements in the end-use environment.

PTFE vs FEP Infographic

materialdif.com

materialdif.com