PTFE and PFA are both fluoropolymer materials widely used in Teflon pet products due to their excellent non-stick and chemical resistance properties. PTFE offers superior temperature resistance and a lower coefficient of friction, making it ideal for high-performance applications, while PFA provides enhanced flexibility, UV resistance, and transparency. Choosing between PTFE and PFA depends on the specific requirements of durability, flexibility, and environmental exposure for the Teflon pet product.

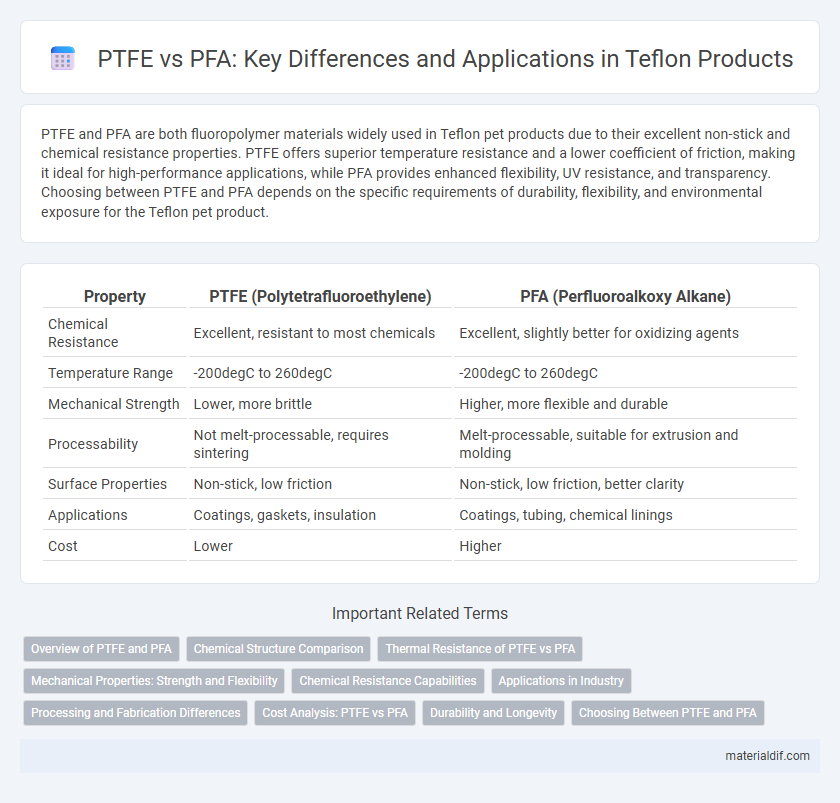

Table of Comparison

| Property | PTFE (Polytetrafluoroethylene) | PFA (Perfluoroalkoxy Alkane) |

|---|---|---|

| Chemical Resistance | Excellent, resistant to most chemicals | Excellent, slightly better for oxidizing agents |

| Temperature Range | -200degC to 260degC | -200degC to 260degC |

| Mechanical Strength | Lower, more brittle | Higher, more flexible and durable |

| Processability | Not melt-processable, requires sintering | Melt-processable, suitable for extrusion and molding |

| Surface Properties | Non-stick, low friction | Non-stick, low friction, better clarity |

| Applications | Coatings, gaskets, insulation | Coatings, tubing, chemical linings |

| Cost | Lower | Higher |

Overview of PTFE and PFA

PTFE (Polytetrafluoroethylene) is a high-performance fluoropolymer known for its exceptional chemical resistance, low friction, and high-temperature stability, commonly used in non-stick coatings and industrial applications. PFA (Perfluoroalkoxy alkane) offers similar chemical resistance and thermal properties as PTFE but features enhanced flexibility, transparency, and processability, making it suitable for complex molding and tubing. Both materials excel in harsh environments, with PTFE favored for rigid, high-temperature uses, while PFA is preferred when superior clarity and ease of fabrication are required.

Chemical Structure Comparison

PTFE (polytetrafluoroethylene) consists of a carbon backbone fully saturated with fluorine atoms, creating a rigid, highly crystalline polymer with strong C-F bonds that offer exceptional chemical resistance. PFA (perfluoroalkoxy alkane) shares a similar fluorinated carbon backbone but includes perfluoroether side chains, providing greater flexibility and improved melt processability while maintaining comparable chemical inertness. The presence of ether linkages in PFA reduces crystallinity compared to PTFE, influencing thermal and mechanical properties without compromising chemical stability.

Thermal Resistance of PTFE vs PFA

PTFE exhibits superior thermal resistance, maintaining stability up to 260degC, while PFA operates efficiently at slightly lower temperatures, typically up to 250degC. Both polymers demonstrate excellent resistance to thermal degradation, but PTFE's higher melting point of 327degC allows for enhanced performance in high-temperature environments. PFA's improved flexibility and transparency make it suitable for applications requiring thermal cycling without compromising its chemical resistance.

Mechanical Properties: Strength and Flexibility

PTFE (Polytetrafluoroethylene) exhibits high tensile strength and excellent chemical resistance but tends to have lower mechanical flexibility compared to PFA (Perfluoroalkoxy). PFA offers enhanced flexibility and superior impact strength, making it more suitable for applications requiring dynamic stress resistance. Both materials resist deformation under load, but PFA's improved elongation at break enables better mechanical resilience in flexible components.

Chemical Resistance Capabilities

Polytetrafluoroethylene (PTFE) exhibits exceptional chemical resistance against aggressive acids, bases, and solvents, making it ideal for harsh chemical environments. Perfluoroalkoxy alkane (PFA) offers comparable chemical resistance while providing better flexibility and higher temperature tolerance. Both PTFE and PFA resist most corrosive substances, but PFA's enhanced thermal stability allows use in applications with frequent thermal cycling or extreme temperature variations.

Applications in Industry

PTFE (Polytetrafluoroethylene) is widely used in industries requiring excellent chemical resistance and high-temperature tolerance, such as chemical processing, electrical insulation, and food manufacturing. PFA (Perfluoroalkoxy alkane), with its superior clarity and melt processability, is preferred for complex molding applications and components exposed to aggressive chemicals in semiconductor and pharmaceutical industries. Both materials offer non-stick properties and outstanding durability, making them essential for lining pipes, valves, and gaskets where contamination prevention and longevity are critical.

Processing and Fabrication Differences

PTFE offers exceptional chemical resistance and high-temperature tolerance but is challenging to process due to its high melting point and lack of melt flow, requiring sintering or compression molding techniques. PFA, a perfluoroalkoxy fluoropolymer, provides similar chemical resistance with improved melt processability, allowing conventional extrusion and injection molding methods for more complex shapes and consistent dimensional tolerance. The ease of PFA processing makes it preferable for intricate designs, while PTFE remains ideal for applications demanding extreme chemical and thermal resistance.

Cost Analysis: PTFE vs PFA

PTFE (Polytetrafluoroethylene) generally offers a lower material cost compared to PFA (Perfluoroalkoxy alkane), making it more cost-effective for large-scale industrial applications. Despite the higher price of PFA, it provides superior chemical resistance and flexibility, which can reduce maintenance and replacement expenses over time. Evaluating total lifecycle costs, including installation, durability, and performance, is crucial for an accurate cost analysis between PTFE and PFA in various engineering applications.

Durability and Longevity

PTFE (Polytetrafluoroethylene) offers exceptional chemical resistance and thermal stability, making it highly durable for most industrial applications. PFA (Perfluoroalkoxy), a melt-processable fluoropolymer, provides greater flexibility and improved resistance to mechanical stress, enhancing its longevity in dynamic environments. Both materials exhibit excellent abrasion resistance, but PFA's superior resistance to cracking and stress fatigue often results in longer service life under continuous mechanical strain.

Choosing Between PTFE and PFA

Choosing between PTFE and PFA depends on specific application requirements such as temperature resistance, chemical compatibility, and mechanical properties. PTFE exhibits superior chemical resistance and higher temperature tolerance up to 260degC, making it ideal for harsh chemical environments, while PFA offers greater flexibility, transparency, and can be processed more easily at lower temperatures. Selecting PTFE is advantageous for static applications requiring extreme thermal and chemical stability, whereas PFA is optimal for dynamic uses where flexibility and ease of fabrication are essential.

PTFE vs PFA Infographic

materialdif.com

materialdif.com