Anti-drip Teflon offers superior non-stick performance by preventing liquid build-up and reducing drips during cooking, unlike standard Teflon coatings which can allow residue to accumulate. This advanced formulation enhances cleanliness and cooking efficiency, making cleanup faster and easier. Choosing anti-drip Teflon improves food release quality and maintains the surface's durability over time.

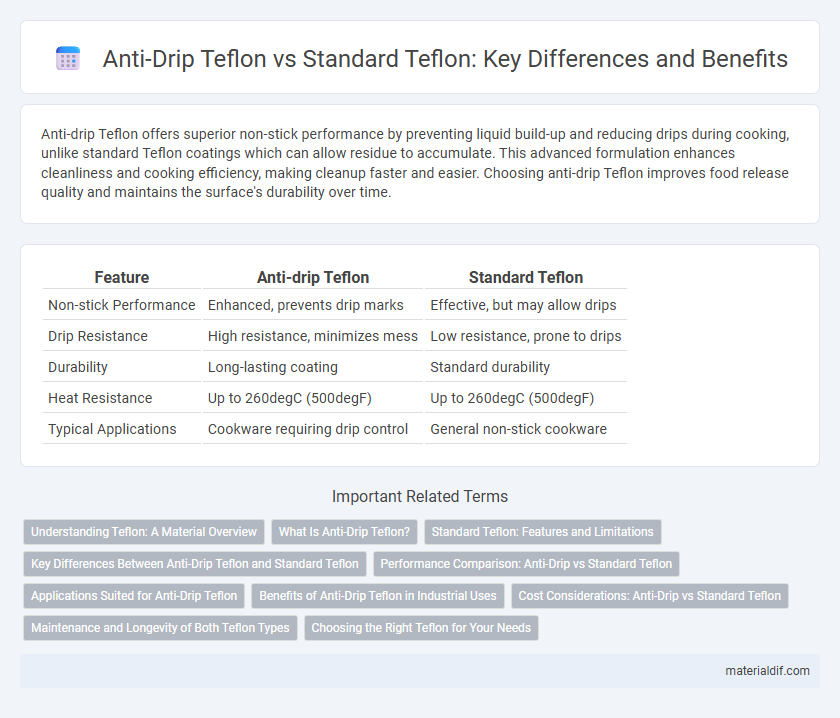

Table of Comparison

| Feature | Anti-drip Teflon | Standard Teflon |

|---|---|---|

| Non-stick Performance | Enhanced, prevents drip marks | Effective, but may allow drips |

| Drip Resistance | High resistance, minimizes mess | Low resistance, prone to drips |

| Durability | Long-lasting coating | Standard durability |

| Heat Resistance | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Typical Applications | Cookware requiring drip control | General non-stick cookware |

Understanding Teflon: A Material Overview

Anti-drip Teflon features a specialized surface treatment that reduces liquid adhesion, preventing drip formation during heating, unlike standard Teflon which primarily offers non-stick properties without enhanced liquid control. Standard Teflon is prized for its chemical resistance and low friction, but anti-drip variants incorporate micro-textured coatings or fluoropolymer blends to improve performance in cookware and industrial applications. This differentiation underscores the material's adaptability, where anti-drip Teflon optimizes user experience by minimizing mess and increasing efficiency compared to the conventional Teflon formulations.

What Is Anti-Drip Teflon?

Anti-drip Teflon features a modified surface that prevents the formation of droplets, enhancing non-stick performance and reducing mess during cooking. Unlike standard Teflon, which can allow liquids to bead and drip, anti-drip variants offer superior liquid repellency and improved durability under high-heat conditions. This innovation is widely used in cookware coatings to ensure cleaner cooking processes and easier maintenance.

Standard Teflon: Features and Limitations

Standard Teflon offers excellent non-stick properties and high chemical resistance, making it ideal for a variety of industrial and cookware applications. However, it tends to experience drip formation at high temperatures, which can lead to material waste and inconsistent coating performance. Its limitations include moderate wear resistance and a lower threshold for drip prevention compared to Anti-drip Teflon formulations.

Key Differences Between Anti-Drip Teflon and Standard Teflon

Anti-drip Teflon features a specialized non-stick coating that prevents oil and grease from dripping, enhancing cooking cleanliness and safety, whereas standard Teflon primarily provides a smooth, non-stick surface without anti-drip properties. The molecular structure in anti-drip Teflon is engineered to repel liquids more effectively, reducing splatter during frying or sauteing. Standard Teflon offers excellent release for food but lacks the moisture control and drip prevention found in anti-drip variants.

Performance Comparison: Anti-Drip vs Standard Teflon

Anti-drip Teflon features enhanced surface tension properties that minimize liquid adhesion, resulting in precise drip control and cleaner application compared to Standard Teflon. Standard Teflon offers excellent non-stick performance and chemical resistance but lacks the specialized anti-drip formulation that prevents excess fluid accumulation. Performance comparisons highlight that Anti-drip Teflon reduces waste and improves efficiency in coating and sealing processes by promoting uniform liquid flow and faster drying times.

Applications Suited for Anti-Drip Teflon

Anti-drip Teflon is ideal for applications requiring precise fluid control and minimal leakage, such as chemical processing, pharmaceutical manufacturing, and food packaging. Its enhanced non-stick properties and drip-resistant formulation reduce contamination risks and improve equipment cleanliness. This makes Anti-drip Teflon superior to standard Teflon in environments where preventing fluid dripping is critical for product quality and safety.

Benefits of Anti-Drip Teflon in Industrial Uses

Anti-drip Teflon enhances industrial applications by preventing unwanted residue and dripping during high-temperature processes, improving product quality and reducing waste. Its superior non-stick properties minimize contamination risks and streamline cleaning, increasing operational efficiency in manufacturing environments. Compared to standard Teflon, anti-drip variants offer enhanced durability and reliability under rigorous industrial conditions.

Cost Considerations: Anti-Drip vs Standard Teflon

Anti-drip Teflon coatings typically incur higher production costs due to advanced formulation and enhanced performance features, resulting in a premium price compared to standard Teflon. Standard Teflon offers a more cost-effective option with reliable non-stick properties, making it suitable for budget-conscious applications. Manufacturers and consumers must weigh the upfront cost difference against the potential long-term savings from reduced cleaning and maintenance with anti-drip variants.

Maintenance and Longevity of Both Teflon Types

Anti-drip Teflon coatings feature enhanced chemical formulations that reduce residue buildup, making maintenance easier compared to standard Teflon, which often requires more frequent cleaning to prevent sticky residue. The advanced durability of anti-drip Teflon extends the non-stick surface lifespan by minimizing degradation from heat and food contact, whereas standard Teflon tends to wear faster under similar conditions. This results in longer-lasting performance and reduced need for re-coating or replacement with anti-drip variants.

Choosing the Right Teflon for Your Needs

Anti-drip Teflon offers enhanced drip resistance, making it ideal for applications requiring clean handling and minimal contamination, while Standard Teflon provides excellent chemical resistance and non-stick properties suitable for general use. Consider the specific environmental conditions and handling requirements of your project, as Anti-drip Teflon reduces drip-related mess in precision processes, whereas Standard Teflon delivers broad versatility and durability. Selecting the right Teflon depends on balancing ease of maintenance with the performance characteristics required for optimal operational efficiency.

Anti-drip Teflon vs Standard Teflon Infographic

materialdif.com

materialdif.com