Teflon membranes offer superior chemical resistance and hydrophobic properties compared to PVDF membranes, making them ideal for applications requiring high durability and low fouling. PVDF membranes provide excellent mechanical strength and are widely used in microfiltration and ultrafiltration processes but may degrade faster in harsh chemical environments. Choosing between Teflon and PVDF membranes depends on the specific filtration needs, with Teflon favored for aggressive solvents and PVDF for general filtration tasks.

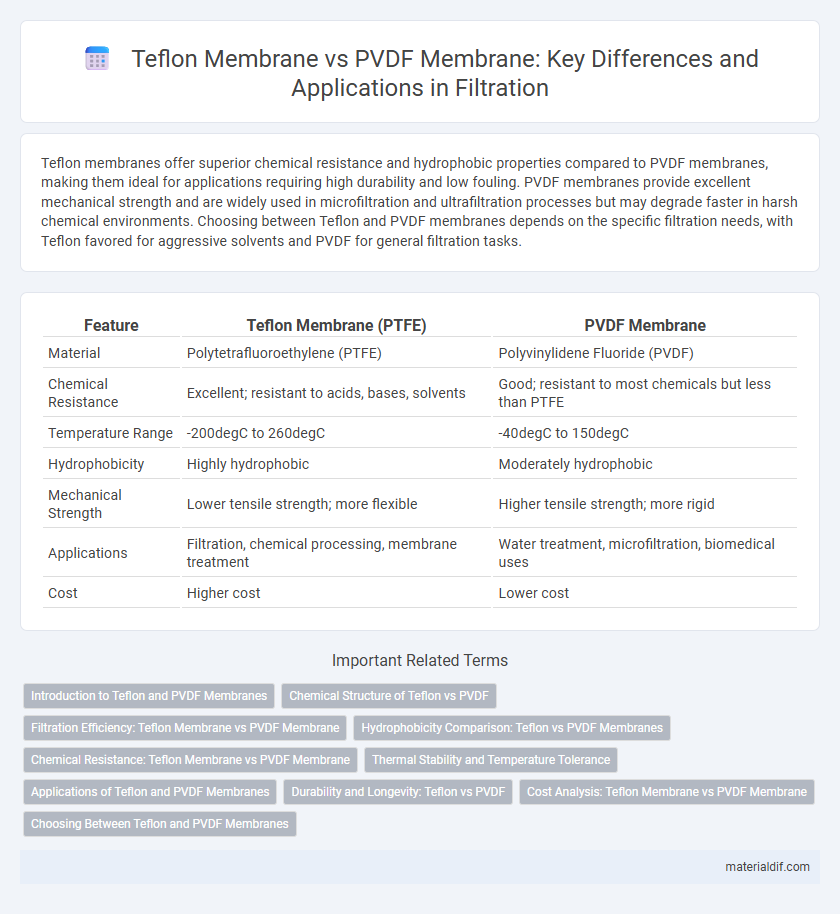

Table of Comparison

| Feature | Teflon Membrane (PTFE) | PVDF Membrane |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Polyvinylidene Fluoride (PVDF) |

| Chemical Resistance | Excellent; resistant to acids, bases, solvents | Good; resistant to most chemicals but less than PTFE |

| Temperature Range | -200degC to 260degC | -40degC to 150degC |

| Hydrophobicity | Highly hydrophobic | Moderately hydrophobic |

| Mechanical Strength | Lower tensile strength; more flexible | Higher tensile strength; more rigid |

| Applications | Filtration, chemical processing, membrane treatment | Water treatment, microfiltration, biomedical uses |

| Cost | Higher cost | Lower cost |

Introduction to Teflon and PVDF Membranes

Teflon membranes, made from expanded polytetrafluoroethylene (ePTFE), exhibit exceptional chemical resistance, hydrophobicity, and thermal stability, making them ideal for filtration and protection applications in aggressive environments. PVDF membranes, composed of polyvinylidene fluoride, offer excellent mechanical strength, chemical resistance, and hydrophilic or hydrophobic properties depending on surface treatment, making them suitable for water treatment and medical uses. Both membranes serve distinct purposes due to their material properties, with Teflon excelling in harsh chemical conditions and PVDF favored for versatile filtration processes.

Chemical Structure of Teflon vs PVDF

The chemical structure of Teflon (polytetrafluoroethylene, PTFE) consists of a carbon backbone fully surrounded by fluorine atoms, providing exceptional chemical inertness and resistance to solvents and acids. In contrast, PVDF (polyvinylidene fluoride) features a carbon chain with alternating fluorine and hydrogen atoms, offering a balance of chemical resistance and mechanical flexibility. This structural difference results in Teflon membranes exhibiting superior chemical stability, while PVDF membranes offer better processability and mechanical strength.

Filtration Efficiency: Teflon Membrane vs PVDF Membrane

Teflon membranes exhibit superior chemical resistance and hydrophobic properties, contributing to enhanced filtration efficiency by preventing clogging and facilitating higher flow rates compared to PVDF membranes. PVDF membranes, while offering excellent mechanical strength and thermal stability, may experience reduced filtration performance in harsh chemical environments due to their semi-hydrophilic nature. Evaluations show that Teflon membranes excel in applications requiring aggressive solvent filtration and long-term durability, maintaining filter integrity and consistent particle retention rates.

Hydrophobicity Comparison: Teflon vs PVDF Membranes

Teflon membranes exhibit superior hydrophobicity compared to PVDF membranes, with water contact angles often exceeding 110deg, enhancing their repellence to moisture and contaminants. The fluorinated polymer structure of Teflon provides exceptional chemical resistance and minimal surface energy, making it ideal for applications requiring robust water resistance. In contrast, PVDF membranes, while hydrophobic, typically show water contact angles around 80-90deg, offering moderate repellence but greater flexibility and mechanical strength in filtration processes.

Chemical Resistance: Teflon Membrane vs PVDF Membrane

Teflon membrane exhibits superior chemical resistance compared to PVDF membrane, maintaining stability in harsh acids, bases, and organic solvents. PVDF membranes resist a broad range of chemicals but degrade faster when exposed to strong oxidizers or high pH environments. The exceptional inertness of Teflon membranes makes them ideal for aggressive chemical filtration and separation processes.

Thermal Stability and Temperature Tolerance

Teflon membranes exhibit superior thermal stability, maintaining structural integrity at temperatures up to 260degC, whereas PVDF membranes typically tolerate temperatures only up to 150degC. This high temperature resistance makes Teflon membranes ideal for applications involving extreme heat or rapid temperature fluctuations. PVDF membranes, while chemically resistant, are less suitable for high-temperature industrial processes compared to Teflon's robust thermal tolerance.

Applications of Teflon and PVDF Membranes

Teflon membranes exhibit exceptional chemical resistance and hydrophobicity, making them ideal for applications such as water filtration in aggressive chemical environments and venting filters in electronic devices. PVDF membranes, known for their thermal stability and excellent mechanical strength, are widely used in microfiltration and ultrafiltration processes in pharmaceuticals, biotechnology, and water treatment. Both membranes are crucial in industrial separation processes but differ in compatibility with specific solvents and mechanical durability requirements.

Durability and Longevity: Teflon vs PVDF

Teflon membranes exhibit superior chemical resistance and withstand harsh environments better than PVDF membranes, resulting in enhanced durability and extended lifespan. PVDF membranes offer good mechanical strength but are more prone to degradation under aggressive chemical exposure compared to Teflon. The inherent non-stick and low-friction properties of Teflon contribute to its longevity, making it ideal for applications requiring long-term membrane performance.

Cost Analysis: Teflon Membrane vs PVDF Membrane

Teflon membranes typically incur higher initial costs compared to PVDF membranes, driven by their superior chemical resistance and long-term durability in aggressive environments. PVDF membranes offer a more affordable option with adequate performance for many standard filtration applications, but may require more frequent replacement, increasing lifecycle expenses. Evaluating total cost of ownership, including maintenance and replacement frequencies, is crucial for selecting between Teflon and PVDF membranes in industrial filtration systems.

Choosing Between Teflon and PVDF Membranes

Teflon membranes offer exceptional chemical resistance and hydrophobic properties, making them ideal for applications requiring strong solvent resistance and moisture repellent surfaces. PVDF membranes provide excellent mechanical strength, thermal stability, and hydrophilic options that improve protein binding and filtration efficiency in biomedical and water treatment uses. Choosing between Teflon and PVDF membranes depends on specific requirements like chemical compatibility, filtration needs, and environmental conditions to ensure optimal performance.

Teflon membrane vs PVDF membrane Infographic

materialdif.com

materialdif.com