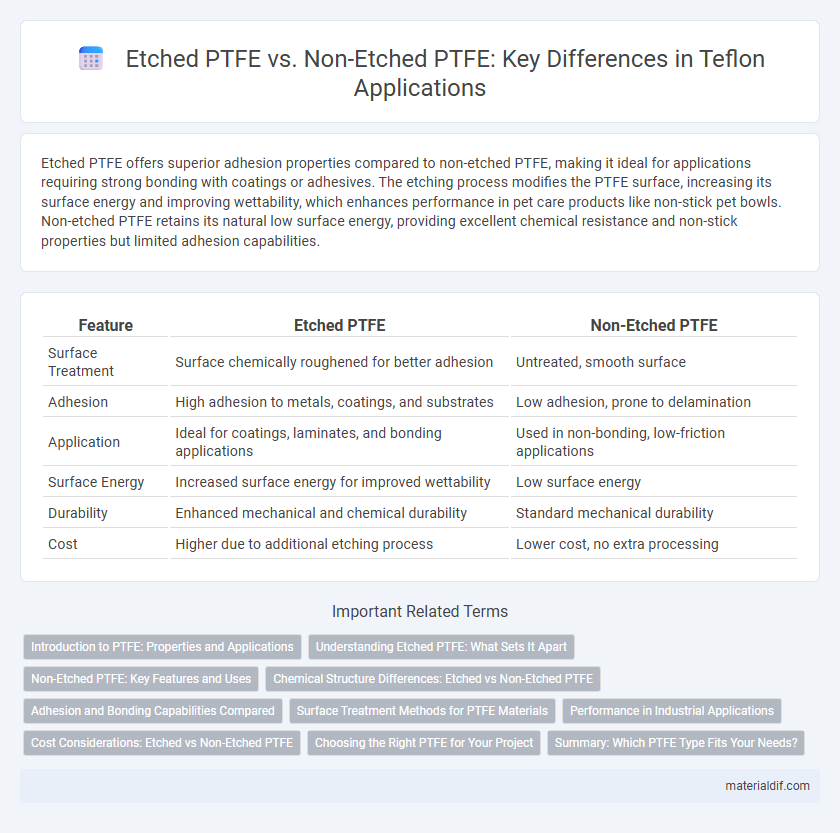

Etched PTFE offers superior adhesion properties compared to non-etched PTFE, making it ideal for applications requiring strong bonding with coatings or adhesives. The etching process modifies the PTFE surface, increasing its surface energy and improving wettability, which enhances performance in pet care products like non-stick pet bowls. Non-etched PTFE retains its natural low surface energy, providing excellent chemical resistance and non-stick properties but limited adhesion capabilities.

Table of Comparison

| Feature | Etched PTFE | Non-Etched PTFE |

|---|---|---|

| Surface Treatment | Surface chemically roughened for better adhesion | Untreated, smooth surface |

| Adhesion | High adhesion to metals, coatings, and substrates | Low adhesion, prone to delamination |

| Application | Ideal for coatings, laminates, and bonding applications | Used in non-bonding, low-friction applications |

| Surface Energy | Increased surface energy for improved wettability | Low surface energy |

| Durability | Enhanced mechanical and chemical durability | Standard mechanical durability |

| Cost | Higher due to additional etching process | Lower cost, no extra processing |

Introduction to PTFE: Properties and Applications

Etched PTFE undergoes surface treatment enhancing adhesion properties without compromising inherent chemical resistance and low friction, making it suitable for demanding industrial applications such as aerospace and electronics. Non-etched PTFE retains its naturally smooth, non-stick, and chemically inert characteristics, ideal for applications requiring extreme corrosion resistance like chemical piping and cookware. Understanding the distinctions between etched and non-etched PTFE is critical for optimizing performance in manufacturing, sealing, and coating processes.

Understanding Etched PTFE: What Sets It Apart

Etched PTFE undergoes a chemical or plasma treatment that modifies its surface, enhancing adhesion properties and allowing for better bonding with inks, adhesives, and coatings compared to non-etched PTFE. This surface alteration creates microscopic pores that increase surface energy, overcoming the naturally low energy and non-stick characteristics of standard PTFE. Understanding etched PTFE's improved surface chemistry is essential for applications requiring stronger material integration and durability.

Non-Etched PTFE: Key Features and Uses

Non-etched PTFE exhibits exceptional chemical resistance, thermal stability up to 260degC, and a naturally low coefficient of friction, making it ideal for applications requiring non-stick and anti-corrosive properties. Its smooth, non-porous surface resists moisture absorption and contamination, ensuring durability in food processing, pharmaceutical equipment, and electrical insulation. Non-etched PTFE's inert nature and electrical insulation capabilities make it a preferred choice for gasketing, seals, and lining materials in harsh environments.

Chemical Structure Differences: Etched vs Non-Etched PTFE

Etched PTFE undergoes a surface treatment that modifies its molecular structure by creating micro-roughness and introducing polar functional groups, enhancing adhesion properties compared to non-etched PTFE, which retains its original smooth, non-polar, and highly crystalline fluoropolymer surface. The chemical structure of non-etched PTFE consists primarily of carbon-fluorine bonds forming a hydrophobic, chemically inert surface, while etching disrupts this uniformity, increasing surface energy and enabling improved bonding with coatings or adhesives. These structural differences significantly impact the performance and application versatility of PTFE in industrial and chemical processing environments.

Adhesion and Bonding Capabilities Compared

Etched PTFE features a chemically treated surface that significantly enhances adhesion by increasing surface energy and creating micro-roughness, enabling stronger bonding with adhesives and coatings compared to non-etched PTFE. Non-etched PTFE maintains its inert, low-energy surface, resulting in poor adhesion and limited bonding capabilities due to its resistance to chemical bonding. This difference makes etched PTFE ideal for applications requiring reliable adhesive strength, such as in electronics and aerospace manufacturing.

Surface Treatment Methods for PTFE Materials

Etched PTFE undergoes chemical or plasma surface treatment to enhance adhesion properties by increasing surface energy and roughness, improving bonding with coatings and adhesives. Non-etched PTFE retains its inherently low surface energy and smooth texture, resulting in poor adhesion and limited compatibility with surface coatings. Surface treatment methods like sodium etching or plasma treatment are essential for modifying PTFE materials to achieve better interfacial bonding in industrial applications.

Performance in Industrial Applications

Etched PTFE offers superior adhesion properties compared to non-etched PTFE, making it ideal for industrial coatings where strong bonding to substrates is critical. Its enhanced surface energy improves paint and adhesive compatibility, resulting in increased durability and resistance to chemicals and wear. Non-etched PTFE maintains excellent chemical inertness but lacks the adhesive performance needed for demanding industrial applications.

Cost Considerations: Etched vs Non-Etched PTFE

Etched PTFE typically incurs higher costs due to the additional surface treatment process that enhances adhesion properties, making it suitable for specialized applications requiring improved bonding. Non-etched PTFE is more cost-effective, favored in applications where surface modification is unnecessary, offering standard chemical resistance and non-stick benefits. Choosing between etched and non-etched PTFE depends on budget constraints and the specific performance requirements of the end-use application.

Choosing the Right PTFE for Your Project

Etched PTFE features a chemically treated surface that enhances adhesion properties, making it ideal for applications requiring strong bonding with adhesives, coatings, or metals. Non-etched PTFE retains its original non-stick and low-friction characteristics, suitable for use cases prioritizing chemical resistance and minimal surface interaction. Selecting between etched and non-etched PTFE depends on whether surface adhesion or chemical inertness is the primary requirement in your project.

Summary: Which PTFE Type Fits Your Needs?

Etched PTFE offers enhanced surface adhesion and improved bonding properties, ideal for applications requiring strong coatings or laminates. Non-etched PTFE provides superior chemical resistance and electrical insulation, suitable for environments demanding high purity and low friction. Choose etched PTFE for better mechanical integration and non-etched PTFE for maximum chemical inertness and performance stability.

Etched PTFE vs Non-Etched PTFE Infographic

materialdif.com

materialdif.com