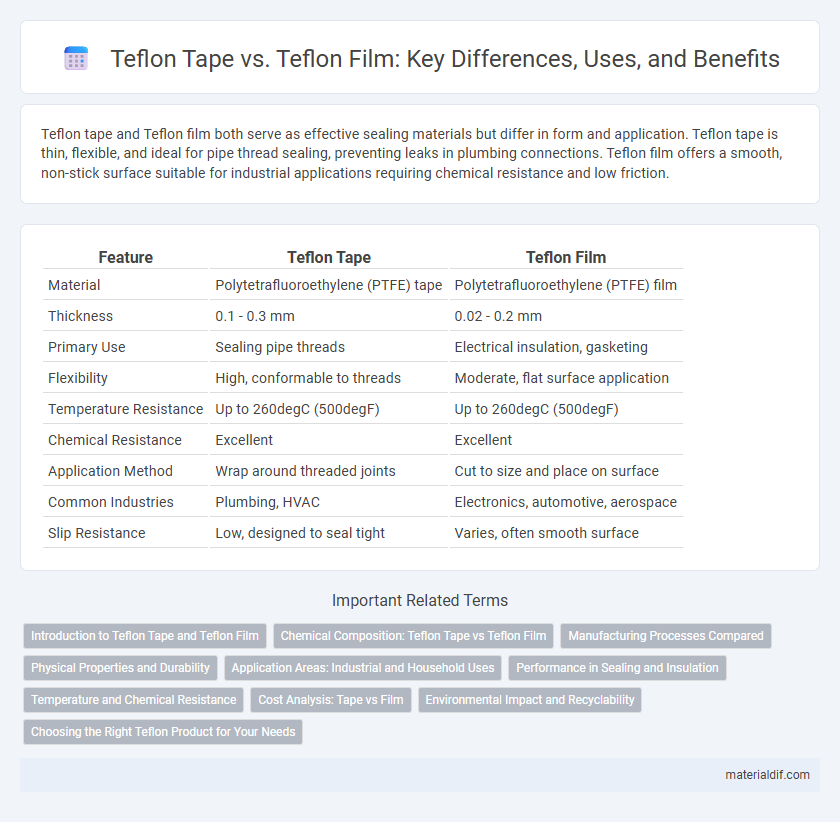

Teflon tape and Teflon film both serve as effective sealing materials but differ in form and application. Teflon tape is thin, flexible, and ideal for pipe thread sealing, preventing leaks in plumbing connections. Teflon film offers a smooth, non-stick surface suitable for industrial applications requiring chemical resistance and low friction.

Table of Comparison

| Feature | Teflon Tape | Teflon Film |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) tape | Polytetrafluoroethylene (PTFE) film |

| Thickness | 0.1 - 0.3 mm | 0.02 - 0.2 mm |

| Primary Use | Sealing pipe threads | Electrical insulation, gasketing |

| Flexibility | High, conformable to threads | Moderate, flat surface application |

| Temperature Resistance | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Chemical Resistance | Excellent | Excellent |

| Application Method | Wrap around threaded joints | Cut to size and place on surface |

| Common Industries | Plumbing, HVAC | Electronics, automotive, aerospace |

| Slip Resistance | Low, designed to seal tight | Varies, often smooth surface |

Introduction to Teflon Tape and Teflon Film

Teflon tape, also known as PTFE thread seal tape, is a thin, flexible strip primarily used to seal pipe threads and prevent leaks in plumbing applications. Teflon film, a versatile fluoropolymer sheet, offers chemical resistance, low friction, and electrical insulation for various industrial uses. Both materials are made from polytetrafluoroethylene but differ in form, function, and application scope.

Chemical Composition: Teflon Tape vs Teflon Film

Teflon tape and Teflon film both consist primarily of polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its high chemical resistance and low friction properties. Teflon tape is typically a thin, flexible form of PTFE designed for sealing pipe threads, while Teflon film is manufactured as a flat, smooth sheet used in various industrial applications requiring a non-stick, heat-resistant surface. The chemical composition remains consistent, but the physical structure and intended use differentiate tape from film in practical applications.

Manufacturing Processes Compared

Teflon tape is produced through a process called skiving, where thin strips are shaved from a Teflon block, resulting in a flexible, adhesive-backed tape ideal for sealing pipe threads. Teflon film, however, is manufactured using an extrusion and calendaring process, creating uniform, non-adhesive sheets with consistent thickness and smooth surfaces for electrical insulation and industrial applications. The precision in extrusion and calendaring allows Teflon film to offer superior mechanical properties and chemical resistance compared to the more conformable, sealing-focused Teflon tape.

Physical Properties and Durability

Teflon tape exhibits excellent flexibility, making it ideal for sealing pipe threads with high resistance to wear and chemical corrosion, while maintaining durability under varying temperature conditions. Teflon film offers superior tensile strength and a smooth surface finish, providing enhanced abrasion resistance and better thermal stability for industrial applications. Both materials possess low friction coefficients, but Teflon film generally outperforms tape in mechanical durability and longevity in harsh environments.

Application Areas: Industrial and Household Uses

Teflon tape is commonly used in plumbing and pipe sealing applications, providing a reliable barrier against leaks in both industrial and household plumbing systems. Teflon film, with its thin, flexible, and non-stick properties, finds broader use in industries such as electronics, food processing, and chemical manufacturing for insulation, anti-corrosion coatings, and surface protection. While Teflon tape focuses on sealing threaded connections, Teflon film excels in applications requiring non-adhesive, heat-resistant, and chemically inert surfaces.

Performance in Sealing and Insulation

Teflon tape excels in sealing applications due to its flexibility and conformability, creating a tight, leak-proof seal in pipe threads and plumbing joints. Teflon film offers superior insulation properties with its high dielectric strength and thermal resistance, making it ideal for electrical and electronic components. Performance-wise, tape provides effective mechanical sealing, while film delivers enhanced electrical insulation and chemical resistance.

Temperature and Chemical Resistance

Teflon tape, commonly used for plumbing sealants, offers excellent chemical resistance up to 260degC but is typically thinner and less durable under extreme heat compared to Teflon film. Teflon film provides superior temperature resistance, often enduring continuous exposure up to 260degC and short-term spikes beyond 300degC, making it ideal for industrial applications requiring robust chemical and thermal performance. Both variants exhibit exceptional resistance to corrosive chemicals and solvents, with Teflon film offering enhanced mechanical strength and longevity in high-temperature environments.

Cost Analysis: Tape vs Film

Teflon tape is generally more cost-effective than Teflon film due to lower manufacturing complexity and material usage, making it a preferred choice for sealing pipe threads and plumbing applications. Teflon film, though more expensive, offers superior chemical resistance, durability, and versatility for protective coatings and industrial applications where performance outweighs initial cost. Evaluating the total cost of ownership, including longevity and specific use-case demands, is crucial when choosing between Teflon tape and film.

Environmental Impact and Recyclability

Teflon tape, commonly used for plumbing, is often less recyclable due to its thin, adhesive-coated structure that complicates separation and processing. Teflon film, used in industrial applications, tends to have a lower environmental impact since it can be manufactured with fewer additives and recycled more efficiently within specialized facilities. Both materials derive from polytetrafluoroethylene (PTFE), but the form and application significantly influence their end-of-life recyclability and overall ecological footprint.

Choosing the Right Teflon Product for Your Needs

Teflon tape, also known as PTFE thread seal tape, is ideal for sealing pipe threads to prevent leaks in plumbing and gas connections, offering flexibility and ease of application in tight spaces. Teflon film, made from expanded PTFE sheets, provides superior non-stick, chemical resistance, and electrical insulation properties suited for industrial gaskets, liners, and protective barriers. Selecting the right Teflon product depends on whether you need a conformable sealing solution for threaded joints or a durable, flat sheet material for advanced chemical or electrical applications.

Teflon Tape vs Teflon Film Infographic

materialdif.com

materialdif.com