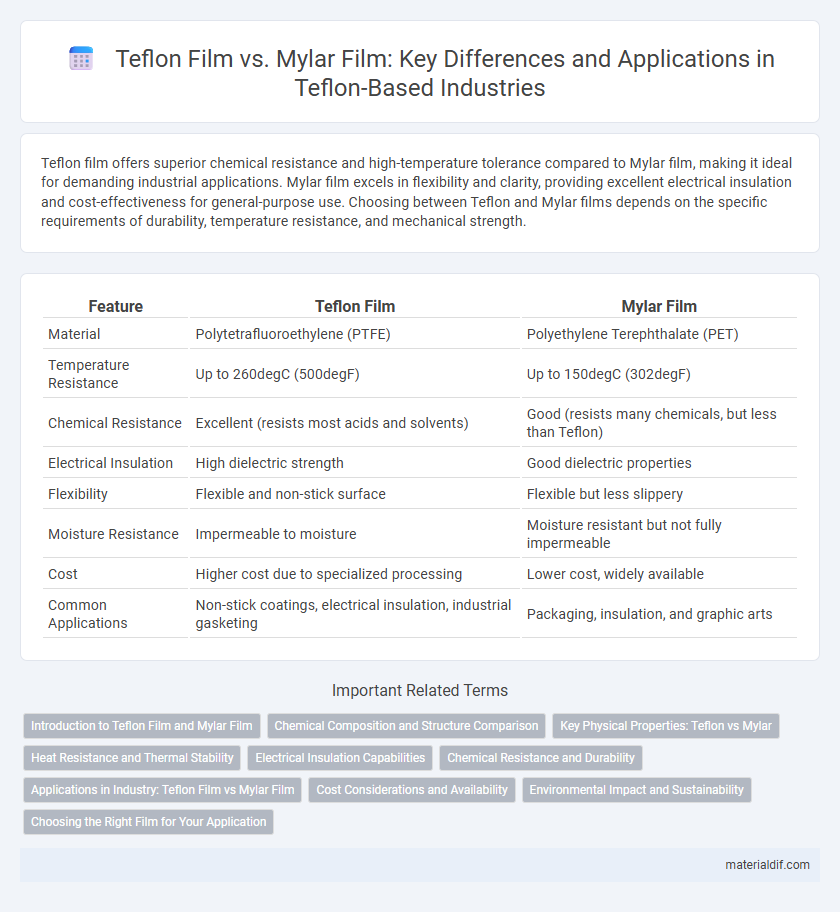

Teflon film offers superior chemical resistance and high-temperature tolerance compared to Mylar film, making it ideal for demanding industrial applications. Mylar film excels in flexibility and clarity, providing excellent electrical insulation and cost-effectiveness for general-purpose use. Choosing between Teflon and Mylar films depends on the specific requirements of durability, temperature resistance, and mechanical strength.

Table of Comparison

| Feature | Teflon Film | Mylar Film |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Polyethylene Terephthalate (PET) |

| Temperature Resistance | Up to 260degC (500degF) | Up to 150degC (302degF) |

| Chemical Resistance | Excellent (resists most acids and solvents) | Good (resists many chemicals, but less than Teflon) |

| Electrical Insulation | High dielectric strength | Good dielectric properties |

| Flexibility | Flexible and non-stick surface | Flexible but less slippery |

| Moisture Resistance | Impermeable to moisture | Moisture resistant but not fully impermeable |

| Cost | Higher cost due to specialized processing | Lower cost, widely available |

| Common Applications | Non-stick coatings, electrical insulation, industrial gasketing | Packaging, insulation, and graphic arts |

Introduction to Teflon Film and Mylar Film

Teflon film, made from polytetrafluoroethylene (PTFE), offers exceptional non-stick properties, chemical resistance, and high-temperature tolerance, making it ideal for industrial applications such as insulation and protective coatings. Mylar film, a type of biaxially-oriented polyethylene terephthalate (BoPET), is known for its excellent tensile strength, dimensional stability, and electrical insulation, commonly used in packaging, electronics, and decorative purposes. Both films serve distinct functions based on their material composition and performance characteristics, with Teflon excelling in extreme environments and Mylar preferred for durability and clarity.

Chemical Composition and Structure Comparison

Teflon film, primarily composed of polytetrafluoroethylene (PTFE), features a highly stable carbon-fluorine bond resulting in exceptional chemical inertness and heat resistance. Mylar film, made from biaxially-oriented polyethylene terephthalate (BoPET), consists of ester groups within its polymer chain, providing moderate chemical resistance and high tensile strength. The distinct molecular structures--Teflon's fully fluorinated carbon backbone versus Mylar's aromatic polyester chain--directly influence their thermal stability and chemical durability in various applications.

Key Physical Properties: Teflon vs Mylar

Teflon film exhibits exceptional chemical resistance, a high melting point around 327degC, and a low coefficient of friction, making it ideal for demanding industrial applications. Mylar film, a polyester film, has a lower melting point near 255degC, excellent dimensional stability, and higher tensile strength but lacks Teflon's superior chemical inertness. Both films offer dielectric properties, yet Teflon's superior thermal stability and non-stick characteristics differentiate it significantly from Mylar in high-temperature environments.

Heat Resistance and Thermal Stability

Teflon film offers superior heat resistance withstanding temperatures up to 260degC (500degF), making it ideal for high-temperature applications where Mylar film's maximum temperature tolerance around 150degC (302degF) is insufficient. The exceptional thermal stability of Teflon film prevents degradation and maintains electrical insulation even under prolonged heat exposure, whereas Mylar film tends to degrade or shrink at elevated temperatures. For industries requiring durable, heat-resistant insulation or protective layers, Teflon film outperforms Mylar in thermal endurance and reliability.

Electrical Insulation Capabilities

Teflon film offers superior electrical insulation properties due to its high dielectric strength of approximately 60-150 kV/mm, making it ideal for applications requiring robust resistance to electrical breakdown. Mylar film, with a dielectric strength around 120-160 kV/mm, provides reliable insulation but tends to have lower thermal stability compared to Teflon, which can limit its effectiveness in high-temperature environments. The exceptional chemical resistance and low dielectric constant of Teflon film enhance its performance in demanding electrical insulation tasks, outperforming Mylar in harsh conditions.

Chemical Resistance and Durability

Teflon film exhibits superior chemical resistance, withstanding aggressive solvents, acids, and bases without degradation, making it ideal for harsh chemical environments. Mylar film, while durable and resistant to moisture and UV light, is less effective against strong chemicals and can degrade over time when exposed to harsh substances. The durability of Teflon film also surpasses Mylar, maintaining its properties at high temperatures and resisting abrasion, which ensures longer service life in demanding industrial applications.

Applications in Industry: Teflon Film vs Mylar Film

Teflon film excels in chemical resistance and high-temperature tolerance, making it ideal for use in gasketing, insulation, and protective coatings in harsh industrial environments. Mylar film offers excellent tensile strength, electrical insulation, and moisture resistance, frequently applied in packaging, electronics, and print media industries. Both materials serve distinct industrial applications based on their unique thermal, chemical, and mechanical properties.

Cost Considerations and Availability

Teflon film typically costs more than Mylar film due to its superior chemical resistance and high-temperature durability, making it ideal for specialized industrial applications. Mylar film is widely available and more affordable, favored for general-purpose insulation, packaging, and protective covers. Availability of Mylar film is higher globally, while Teflon film may require sourcing from specialized suppliers, impacting lead times and overall project costs.

Environmental Impact and Sustainability

Teflon film, made from polytetrafluoroethylene (PTFE), is chemically inert and resistant to degradation, contributing to its environmental persistence and challenges in recycling, whereas Mylar film, composed of biaxially-oriented polyethylene terephthalate (BoPET), is more widely recyclable and biodegradable under industrial conditions. The production of Teflon involves fluorinated chemicals with higher global warming potential and possible release of toxic substances during manufacturing, while Mylar's manufacturing process typically entails lower emissions and less environmental toxicity. In sustainable applications, Mylar is preferred due to its recyclability and reduced ecological footprint, though Teflon's durability in harsh environments may justify its use where long-term performance is critical.

Choosing the Right Film for Your Application

Teflon film offers superior chemical resistance and high-temperature durability, making it ideal for industrial applications requiring non-stick surfaces and insulation up to 260degC. Mylar film, known for its excellent tensile strength, dimensional stability, and clarity, suits applications needing electrical insulation and moisture resistance at lower temperatures around 150degC. Selecting the right film depends on specific requirements such as thermal tolerance, chemical exposure, mechanical strength, and transparency.

Teflon Film vs Mylar Film Infographic

materialdif.com

materialdif.com