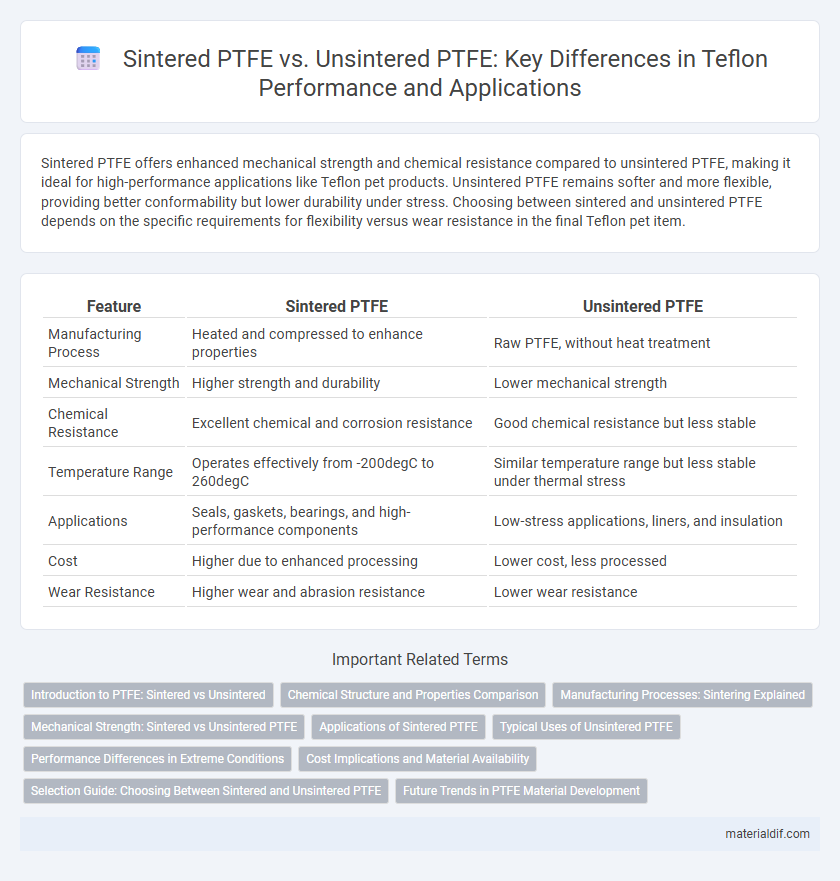

Sintered PTFE offers enhanced mechanical strength and chemical resistance compared to unsintered PTFE, making it ideal for high-performance applications like Teflon pet products. Unsintered PTFE remains softer and more flexible, providing better conformability but lower durability under stress. Choosing between sintered and unsintered PTFE depends on the specific requirements for flexibility versus wear resistance in the final Teflon pet item.

Table of Comparison

| Feature | Sintered PTFE | Unsintered PTFE |

|---|---|---|

| Manufacturing Process | Heated and compressed to enhance properties | Raw PTFE, without heat treatment |

| Mechanical Strength | Higher strength and durability | Lower mechanical strength |

| Chemical Resistance | Excellent chemical and corrosion resistance | Good chemical resistance but less stable |

| Temperature Range | Operates effectively from -200degC to 260degC | Similar temperature range but less stable under thermal stress |

| Applications | Seals, gaskets, bearings, and high-performance components | Low-stress applications, liners, and insulation |

| Cost | Higher due to enhanced processing | Lower cost, less processed |

| Wear Resistance | Higher wear and abrasion resistance | Lower wear resistance |

Introduction to PTFE: Sintered vs Unsintered

Sintered PTFE undergoes a controlled heating process just below its melting point, enhancing its mechanical strength, wear resistance, and dimensional stability compared to unsintered PTFE. Unsintered PTFE remains in its raw, softened state, offering greater flexibility but lower durability and resistance to deformation under stress. Understanding the differences between sintered and unsintered PTFE is crucial for selecting the appropriate material in applications requiring specific performance characteristics like chemical inertness, temperature tolerance, and mechanical integrity.

Chemical Structure and Properties Comparison

Sintered PTFE undergoes a heating process that fuses its polymer particles, resulting in enhanced crystallinity and improved mechanical strength compared to unsintered PTFE, which remains in a more amorphous and less dense form. The sintering process increases resistance to chemical attack and thermal stability by reducing microporosity and enhancing molecular alignment, while unsintered PTFE exhibits greater flexibility but lower durability under harsh chemical environments. Both forms retain excellent non-reactivity and low friction coefficients, but sintered PTFE offers superior wear resistance and dimensional stability for demanding industrial applications.

Manufacturing Processes: Sintering Explained

Sintered PTFE undergoes a controlled heating process where powdered polytetrafluoroethylene is compressed and heated below its melting point, resulting in a dense, mechanically robust material with enhanced chemical resistance. Unsintered PTFE remains in a softened, pliable state due to the absence of this heat treatment, providing higher elasticity but lower mechanical strength. The sintering process significantly improves wear resistance and dimensional stability, making sintered PTFE ideal for demanding industrial applications.

Mechanical Strength: Sintered vs Unsintered PTFE

Sintered PTFE exhibits significantly higher mechanical strength compared to unsintered PTFE due to its enhanced molecular bonding achieved through the sintering process, which involves heating the material just below its melting point. This increased structural integrity results in improved wear resistance, dimensional stability, and load-bearing capacity, making sintered PTFE preferable for demanding industrial applications. Unsintered PTFE, being softer and more pliable, offers less mechanical strength but provides superior conformability for dynamic seals and gaskets.

Applications of Sintered PTFE

Sintered PTFE offers enhanced mechanical strength and chemical resistance, making it ideal for demanding applications such as seals, gaskets, and valve components in chemical processing and pharmaceuticals. Its improved wear resistance and dimensional stability under high temperatures expand its use in aerospace, automotive, and food processing industries. These properties ensure reliable performance in environments with aggressive chemicals and extreme thermal conditions.

Typical Uses of Unsintered PTFE

Unsintered PTFE is commonly used for applications requiring flexibility and conformability, such as gaskets, seals, and protective coatings where low friction and chemical resistance are critical. Its non-sintered form allows for easier processing into thin films and sheets, making it suitable for electrical insulation and medical devices. Unlike sintered PTFE, unsintered PTFE offers superior elongation and deformability, ideal for intricate seals and custom-molded components.

Performance Differences in Extreme Conditions

Sintered PTFE offers superior mechanical strength, enhanced chemical resistance, and higher temperature tolerance compared to unsintered PTFE, making it ideal for extreme environments. Unsintered PTFE retains greater flexibility but exhibits lower wear resistance and thermal stability, limiting its effectiveness under high pressure or temperature. The sintering process enables denser polymer chains, resulting in improved durability and consistent performance in harsh industrial applications.

Cost Implications and Material Availability

Sintered PTFE typically incurs higher costs than unsintered PTFE due to the additional heating and cooling processes required for sintering, which enhances its mechanical properties and durability. Unsintered PTFE remains more readily available and cost-effective for applications with less demanding performance criteria. Businesses often balance the higher upfront investment of sintered PTFE against its longer lifespan and superior wear resistance in critical uses.

Selection Guide: Choosing Between Sintered and Unsintered PTFE

Sintered PTFE offers enhanced mechanical strength, chemical resistance, and temperature tolerance, making it ideal for high-performance applications such as seals, gaskets, and bearings in extreme conditions. Unsintered PTFE, being softer and more pliable, is preferred for applications requiring excellent conformability and low friction, like linings and coatings. Selection between sintered and unsintered PTFE hinges on balancing factors like durability, flexibility, and operating environment to ensure optimal performance.

Future Trends in PTFE Material Development

Sintered PTFE exhibits enhanced mechanical strength and temperature resistance compared to unsintered PTFE, making it preferable for advanced industrial applications. Future trends in PTFE material development emphasize nanocomposite enhancements and bio-based PTFE alternatives to improve durability and environmental sustainability. Innovations in sintering techniques are expected to yield superior microstructural properties, driving broader adoption in aerospace, automotive, and medical sectors.

Sintered PTFE vs Unsintered PTFE Infographic

materialdif.com

materialdif.com