Skived PTFE offers a smoother surface finish and tighter thickness tolerances compared to molded PTFE, making it ideal for applications requiring precision and minimal friction. Molded PTFE typically provides higher density and superior chemical resistance, which is beneficial for heavy-duty sealing and wear-resistant components. Choosing between skived and molded PTFE depends on the specific performance requirements, such as flexibility, strength, and dimensional accuracy in Teflon pet products.

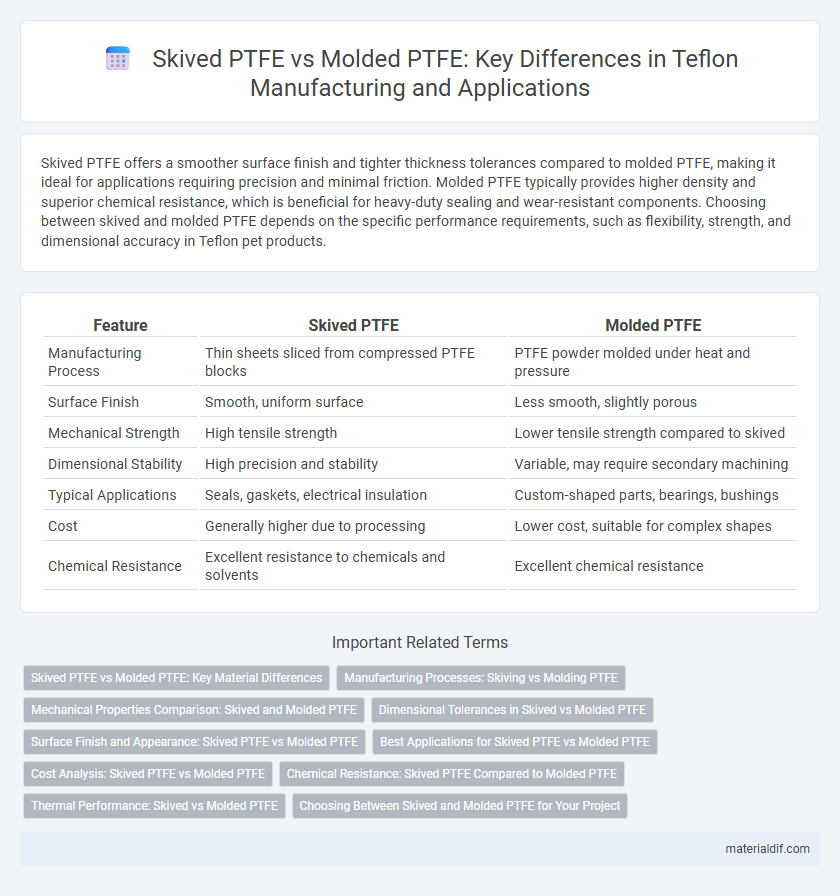

Table of Comparison

| Feature | Skived PTFE | Molded PTFE |

|---|---|---|

| Manufacturing Process | Thin sheets sliced from compressed PTFE blocks | PTFE powder molded under heat and pressure |

| Surface Finish | Smooth, uniform surface | Less smooth, slightly porous |

| Mechanical Strength | High tensile strength | Lower tensile strength compared to skived |

| Dimensional Stability | High precision and stability | Variable, may require secondary machining |

| Typical Applications | Seals, gaskets, electrical insulation | Custom-shaped parts, bearings, bushings |

| Cost | Generally higher due to processing | Lower cost, suitable for complex shapes |

| Chemical Resistance | Excellent resistance to chemicals and solvents | Excellent chemical resistance |

Skived PTFE vs Molded PTFE: Key Material Differences

Skived PTFE offers superior dimensional stability and a smoother surface finish compared to molded PTFE, making it ideal for applications requiring tight tolerances and low friction. Molded PTFE provides higher mechanical strength and is generally more cost-effective for thicker, less precise components. Differences in porosity and density also influence chemical resistance and wear properties, with skived PTFE typically exhibiting lower porosity and enhanced durability in dynamic environments.

Manufacturing Processes: Skiving vs Molding PTFE

Skived PTFE is produced by slicing thin layers from extruded PTFE blocks, resulting in uniform sheets with smooth surfaces ideal for precise applications. Molded PTFE, on the other hand, is created by compressing and heating PTFE powders into desired shapes, offering complex geometries and robust mechanical strength. The skiving process allows for tighter thickness tolerances, while molding provides enhanced material density and isotropic properties.

Mechanical Properties Comparison: Skived and Molded PTFE

Skived PTFE exhibits higher tensile strength and superior flexural modulus compared to molded PTFE due to its dense, oriented molecular structure. Molded PTFE often shows better elongation at break and impact resistance because of its isotropic, less dense matrix. Mechanical performance differences are critical for selecting PTFE types in applications requiring specific strength, flexibility, or durability characteristics.

Dimensional Tolerances in Skived vs Molded PTFE

Skived PTFE typically offers tighter dimensional tolerances compared to molded PTFE, making it ideal for applications requiring precision thickness and uniformity. Skived sheets can achieve thickness variations as low as +-0.002 inches, while molded PTFE generally exhibits tolerances around +-0.005 inches due to the uneven cooling and shrinkage in the molding process. This precision in skived PTFE is critical for sealing, gasketing, and insulating components where consistent thickness impacts performance and reliability.

Surface Finish and Appearance: Skived PTFE vs Molded PTFE

Skived PTFE offers a smoother surface finish and cleaner appearance due to the mechanical slicing process, resulting in reduced surface imperfections and tighter thickness tolerances. Molded PTFE typically exhibits a rougher texture with visible grain patterns and occasional surface blemishes from the molding process, impacting visual uniformity. These differences make skived PTFE preferable in applications requiring superior surface aesthetics and consistent dimensional accuracy.

Best Applications for Skived PTFE vs Molded PTFE

Skived PTFE offers superior surface finish and dimensional stability, making it ideal for applications requiring low friction and precision seals, such as gaskets, valve seats, and electrical insulators. Molded PTFE is preferable for complex geometries and thicker components used in chemical processing equipment, pump parts, and corrosion-resistant linings due to its structural integrity. Skived PTFE is best for thin, flexible sheets, while molded PTFE excels in heavy-duty, high-strength parts where uniform density is critical.

Cost Analysis: Skived PTFE vs Molded PTFE

Skived PTFE typically incurs higher manufacturing costs due to the precision slicing process and material waste, whereas molded PTFE offers cost advantages with bulk production and minimal post-processing requirements. Molded PTFE's cost efficiency is enhanced by shorter cycle times and lower tooling expenses compared to the labor-intensive skiving technique. Cost analysis reveals molded PTFE as the preferred option for large-volume applications, while skived PTFE suits specialized, high-precision needs despite its higher price point.

Chemical Resistance: Skived PTFE Compared to Molded PTFE

Skived PTFE offers superior chemical resistance compared to molded PTFE due to its dense, less porous structure, which minimizes chemical permeation and enhances durability in aggressive environments. The skiving process creates a smoother surface that resists chemical attack better than the slightly more porous and irregular surface of molded PTFE. This makes skived PTFE ideal for applications requiring high chemical inertness, such as seals and gaskets in corrosive media.

Thermal Performance: Skived vs Molded PTFE

Skived PTFE exhibits superior thermal performance compared to molded PTFE due to its dense, uniform structure that enhances heat resistance and thermal conductivity. Molded PTFE, while effective for many applications, tends to have a more porous composition, resulting in slightly lower thermal stability and higher susceptibility to thermal degradation. The selection between skived and molded PTFE should consider the specific temperature ranges and thermal stress conditions of the application for optimal performance.

Choosing Between Skived and Molded PTFE for Your Project

Skived PTFE offers superior surface finish and tighter dimensional tolerances compared to Molded PTFE, making it ideal for applications requiring precision and smoothness, such as sealing and gasket manufacturing. Molded PTFE is more cost-effective for complex shapes and larger parts, providing excellent chemical resistance and purity without secondary machining processes. Selecting between Skived and Molded PTFE depends on your project's tolerance requirements, surface finish needs, and budget constraints.

Skived PTFE vs Molded PTFE Infographic

materialdif.com

materialdif.com