Teflon gaskets provide superior chemical resistance and high-temperature stability, making them ideal for static sealing applications where durability is essential. Teflon seals, on the other hand, offer flexibility and a tight fit for dynamic sealing, especially in rotating or reciprocating equipment. Choosing between Teflon gaskets and Teflon seals depends on the specific requirements of pressure, movement, and temperature within the system.

Table of Comparison

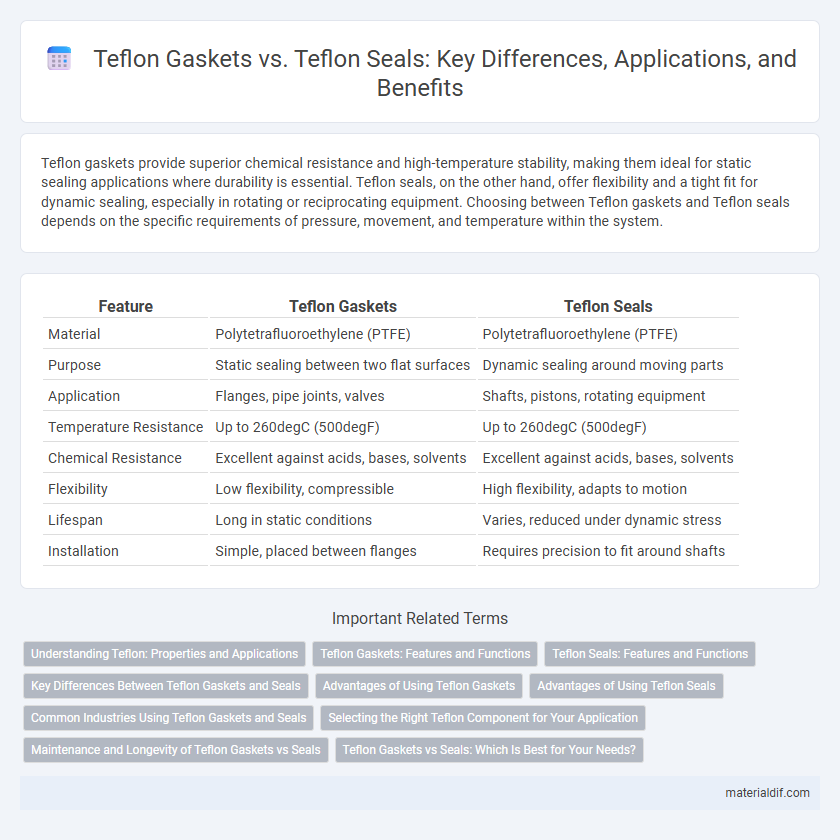

| Feature | Teflon Gaskets | Teflon Seals |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Polytetrafluoroethylene (PTFE) |

| Purpose | Static sealing between two flat surfaces | Dynamic sealing around moving parts |

| Application | Flanges, pipe joints, valves | Shafts, pistons, rotating equipment |

| Temperature Resistance | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Chemical Resistance | Excellent against acids, bases, solvents | Excellent against acids, bases, solvents |

| Flexibility | Low flexibility, compressible | High flexibility, adapts to motion |

| Lifespan | Long in static conditions | Varies, reduced under dynamic stress |

| Installation | Simple, placed between flanges | Requires precision to fit around shafts |

Understanding Teflon: Properties and Applications

Teflon gaskets and Teflon seals both leverage polytetrafluoroethylene's (PTFE) exceptional chemical resistance, low friction, and high-temperature tolerance, making them ideal for aggressive chemical environments and industrial applications. Teflon gaskets provide reliable static sealing between flanged connections, preventing leakage under high pressure and corrosive conditions, while Teflon seals offer dynamic sealing solutions by accommodating movement in rotating or reciprocating shafts. Understanding Teflon's non-stick properties, wide temperature range (-200degC to 260degC), and inertness is crucial for selecting the right component to ensure durability and optimal performance in chemical processing, food production, and pharmaceutical industries.

Teflon Gaskets: Features and Functions

Teflon gaskets are prized for their exceptional chemical resistance, high temperature tolerance up to 260degC, and excellent non-stick properties, making them ideal for sealing applications in harsh industrial environments. Unlike Teflon seals, gaskets provide a flat, compression-based seal that effectively prevents leaks between flanged surfaces in piping and equipment assemblies. Their low friction coefficient and inertness to corrosive substances ensure long-lasting performance in chemical processing, food production, and pharmaceutical industries.

Teflon Seals: Features and Functions

Teflon seals are engineered for superior chemical resistance and high-temperature tolerance, making them ideal for harsh industrial applications. Their low friction properties ensure smooth operation and extended lifespan in dynamic sealing environments. These seals effectively prevent leakage by providing a tight, flexible barrier against fluids and gases under varying pressure conditions.

Key Differences Between Teflon Gaskets and Seals

Teflon gaskets and seals differ primarily in their design and application; gaskets are flat, flexible materials used to fill gaps between two surfaces for leak prevention, while seals are typically molded or shaped components designed to prevent fluid or gas leakage in dynamic environments. Teflon gaskets excel in providing chemical resistance and temperature tolerance in static sealing applications, whereas Teflon seals offer superior performance in dynamic settings due to their elasticity and wear resistance. Key distinctions include the type of stress each withstands--gaskets handle compressive forces, seals endure friction and movement--making the choice dependent on the specific industrial sealing requirement.

Advantages of Using Teflon Gaskets

Teflon gaskets offer superior chemical resistance and excellent temperature tolerance, making them ideal for aggressive environments where leaks must be prevented. Their non-stick properties reduce friction and wear, enhancing durability and maintaining tight seals over extended periods. Compared to Teflon seals, gaskets provide more uniform compression, ensuring a reliable barrier against fluid and gas leakage in high-pressure applications.

Advantages of Using Teflon Seals

Teflon seals offer superior chemical resistance and thermal stability compared to Teflon gaskets, making them ideal for high-temperature and corrosive environments. Their enhanced flexibility and ability to maintain a tight seal under varying pressure conditions reduce the risk of leaks and equipment failure. The non-stick properties of Teflon seals also minimize friction and wear, prolonging the lifespan of machinery components.

Common Industries Using Teflon Gaskets and Seals

Teflon gaskets and seals are widely utilized across chemical processing, pharmaceutical, and food manufacturing industries due to their exceptional chemical resistance and non-reactive properties. In automotive and aerospace sectors, these components provide reliable sealing in high-temperature and high-pressure environments, ensuring safety and efficiency. Water treatment and semiconductor manufacturing also rely on Teflon seals and gaskets for their purity and ability to withstand corrosive substances without contaminating sensitive processes.

Selecting the Right Teflon Component for Your Application

Teflon gaskets provide excellent chemical resistance and are ideal for sealing flanges and static joints, while Teflon seals offer superior performance in dynamic applications with rotating or reciprocating motion. Selecting the right Teflon component depends on factors such as temperature range, pressure conditions, and compatibility with the chemicals involved. Understanding these parameters ensures optimal durability and leak prevention in industrial environments.

Maintenance and Longevity of Teflon Gaskets vs Seals

Teflon gaskets offer superior chemical resistance and thermal stability, which significantly enhances their longevity in harsh industrial environments compared to Teflon seals. Maintenance requirements for Teflon gaskets are minimal due to their non-stick surface and ability to withstand extreme temperatures without deformation. In contrast, Teflon seals may require more frequent inspection and replacement because their sealing efficiency can degrade under repetitive mechanical stress and thermal cycling.

Teflon Gaskets vs Seals: Which Is Best for Your Needs?

Teflon gaskets offer excellent chemical resistance and flexibility, making them ideal for static sealing applications where irregular surfaces are common. Teflon seals, on the other hand, provide superior dynamic performance by maintaining tight seals in moving parts such as valves and pumps, thanks to their low friction and wear resistance. Choosing between Teflon gaskets and seals depends on your specific application requirements--static sealing favors gaskets, while dynamic environments necessitate reliable seals.

Teflon Gaskets vs Teflon Seals Infographic

materialdif.com

materialdif.com