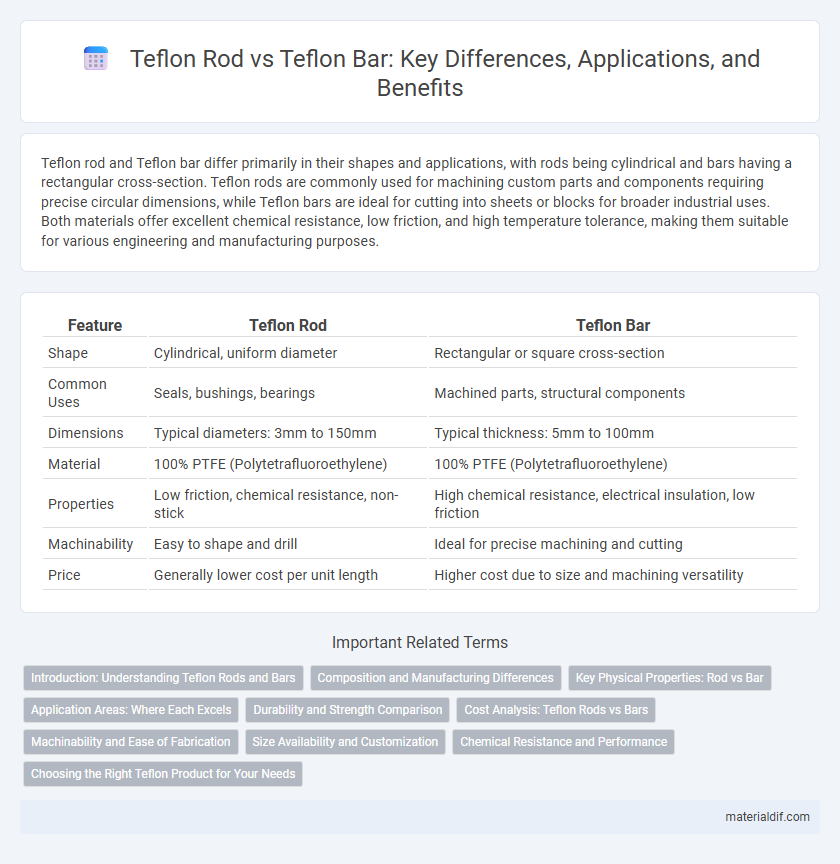

Teflon rod and Teflon bar differ primarily in their shapes and applications, with rods being cylindrical and bars having a rectangular cross-section. Teflon rods are commonly used for machining custom parts and components requiring precise circular dimensions, while Teflon bars are ideal for cutting into sheets or blocks for broader industrial uses. Both materials offer excellent chemical resistance, low friction, and high temperature tolerance, making them suitable for various engineering and manufacturing purposes.

Table of Comparison

| Feature | Teflon Rod | Teflon Bar |

|---|---|---|

| Shape | Cylindrical, uniform diameter | Rectangular or square cross-section |

| Common Uses | Seals, bushings, bearings | Machined parts, structural components |

| Dimensions | Typical diameters: 3mm to 150mm | Typical thickness: 5mm to 100mm |

| Material | 100% PTFE (Polytetrafluoroethylene) | 100% PTFE (Polytetrafluoroethylene) |

| Properties | Low friction, chemical resistance, non-stick | High chemical resistance, electrical insulation, low friction |

| Machinability | Easy to shape and drill | Ideal for precise machining and cutting |

| Price | Generally lower cost per unit length | Higher cost due to size and machining versatility |

Introduction: Understanding Teflon Rods and Bars

Teflon rods and bars are solid forms of polytetrafluoroethylene (PTFE) widely used for their non-stick, chemical-resistant, and low-friction properties. Teflon rods typically refer to cylindrical shapes used in manufacturing bushings, bearings, and seals, while Teflon bars are usually rectangular or square profiles suited for machining into various components. Understanding the differences in shape and application helps optimize material selection for industrial and engineering needs.

Composition and Manufacturing Differences

Teflon rod and Teflon bar differ primarily in their manufacturing processes, with rods typically produced through precise extrusion methods, resulting in uniform diameters ideal for machining into custom parts. Bars are commonly fabricated by compression molding, allowing for larger cross-sectional areas and diverse shapes suitable for heavy-duty industrial applications. Both products share the same composition of polytetrafluoroethylene (PTFE), but the variation in manufacturing impacts their mechanical properties and surface finish quality.

Key Physical Properties: Rod vs Bar

Teflon rods exhibit superior dimensional stability and resistance to deformation under mechanical stress compared to Teflon bars, which often come in larger, bulkier forms suitable for custom machining. Both rods and bars possess excellent chemical resistance, low friction coefficients, and high-temperature tolerance up to 260degC, but rods typically offer more precise diameter control and smoother surface finishes. The choice between a Teflon rod and bar depends on required physical properties such as tensile strength, elongation, and application-specific dimensions.

Application Areas: Where Each Excels

Teflon rods excel in precision machining applications, making them ideal for components in chemical processing equipment and electrical insulation due to their high purity and dimensional stability. Teflon bars are favored in manufacturing larger, structural parts for food processing machinery and medical devices, offering superior chemical resistance and ease of fabrication in bulk quantities. Both materials provide excellent non-stick properties and temperature resistance, but the choice depends on the scale and specificity of the application requirements.

Durability and Strength Comparison

Teflon rods typically offer improved durability and strength due to their uniform cross-section and ability to withstand mechanical stress better than Teflon bars. The manufacturing process of Teflon rods often results in fewer internal defects, enhancing tensile strength and resistance to wear. While Teflon bars are suitable for broader applications, rods provide superior performance in high-stress environments requiring consistent durability.

Cost Analysis: Teflon Rods vs Bars

Teflon rods typically present a cost advantage over Teflon bars due to their standardized dimensions and lower material usage, making them ideal for applications requiring precise machining. Teflon bars often incur higher expenses because of their larger size and increased raw material costs, which can lead to greater waste if not fully utilized. Evaluating the specific requirements of a project can optimize material costs, balancing the price differences between rods and bars in manufacturing processes.

Machinability and Ease of Fabrication

Teflon rods offer superior machinability due to their uniform density and typically smaller diameters, allowing for precise shaping in intricate applications. Teflon bars, with larger cross-sections, require specialized equipment and slower machining speeds to prevent material deformation or overheating. Both forms provide excellent chemical resistance and low friction, but rods are generally preferred for detailed fabrication, while bars serve better in heavy-duty or bulk machining projects.

Size Availability and Customization

Teflon rods are available in a broad range of diameters, typically from 1/8 inch to 8 inches, allowing precise customization for small to medium-sized applications. Teflon bars, on the other hand, are larger and come in standard rectangular or square cross-sections, often used for cutting into specific shapes or sizes. Customization options for Teflon rods focus on length and diameter, while Teflon bars offer greater flexibility in thickness and width adjustments for industrial fabrication needs.

Chemical Resistance and Performance

Teflon rods and bars both offer exceptional chemical resistance, making them ideal for use in harsh chemical environments such as acid tanks and piping systems. Teflon rods often provide more uniform density and consistent performance in precision applications, while Teflon bars are typically preferred for larger-scale fabrication due to their availability in bigger sizes. Both forms maintain excellent non-stick properties and withstand high temperatures, ensuring reliable performance in aggressive chemical conditions.

Choosing the Right Teflon Product for Your Needs

Teflon rods offer precise diameter options ideal for machining custom parts, while Teflon bars provide larger stock sizes suited for cutting multiple components or shaping thicker pieces. Selecting the right Teflon product depends on project scope, with rods favored for smaller, detailed applications and bars preferred for extensive fabrication tasks. Consider mechanical requirements and processing methods to ensure optimal performance and material efficiency.

Teflon Rod vs Teflon Bar Infographic

materialdif.com

materialdif.com