Teflon tape provides a clean, easy-to-apply seal for threaded pipe connections, preventing leaks and resisting chemical corrosion. Pipe dope, a paste applied to pipe threads, offers a more pliable seal that can fill minor imperfections and provides lubrication for easier assembly. Choosing between Teflon tape and pipe dope depends on the application, with tape favored for quick, dry sealing and pipe dope preferred for heavy-duty or metal-to-metal joints.

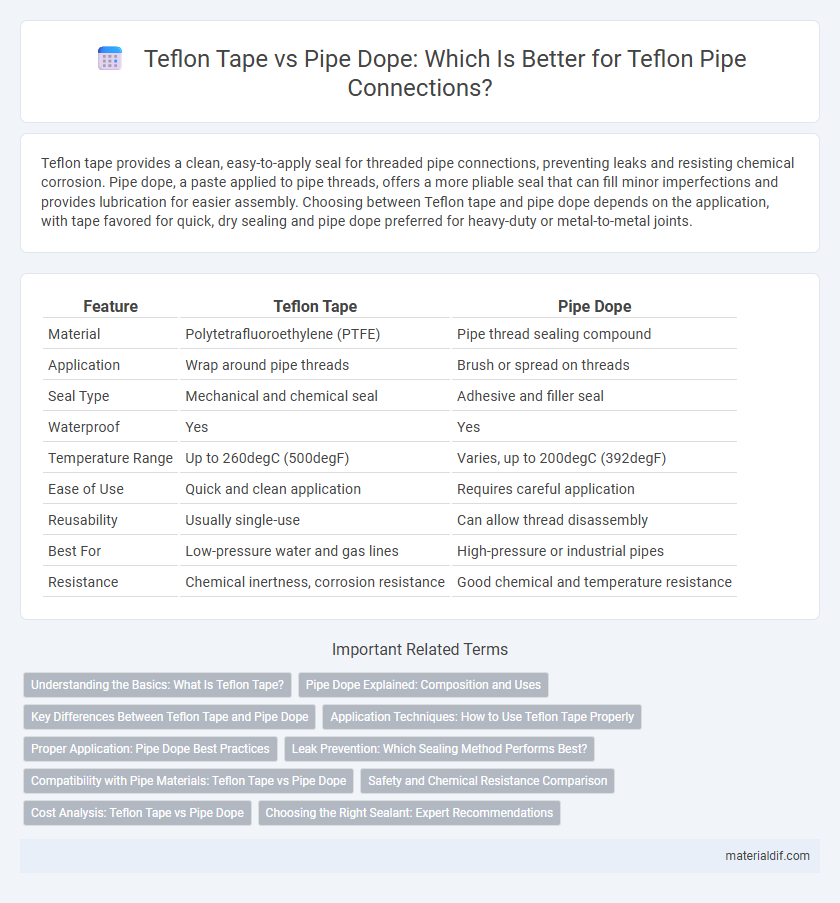

Table of Comparison

| Feature | Teflon Tape | Pipe Dope |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Pipe thread sealing compound |

| Application | Wrap around pipe threads | Brush or spread on threads |

| Seal Type | Mechanical and chemical seal | Adhesive and filler seal |

| Waterproof | Yes | Yes |

| Temperature Range | Up to 260degC (500degF) | Varies, up to 200degC (392degF) |

| Ease of Use | Quick and clean application | Requires careful application |

| Reusability | Usually single-use | Can allow thread disassembly |

| Best For | Low-pressure water and gas lines | High-pressure or industrial pipes |

| Resistance | Chemical inertness, corrosion resistance | Good chemical and temperature resistance |

Understanding the Basics: What Is Teflon Tape?

Teflon tape, also known as PTFE tape, is a thin, white polytetrafluoroethylene film used to seal pipe threads by filling the gaps and preventing leaks. It is popular for its ease of use, resistance to chemicals, and ability to lubricate threads for tighter connections. Unlike pipe dope, which is a paste-like sealant, Teflon tape provides a dry, clean, and non-hardening seal ideal for water, gas, and air fittings.

Pipe Dope Explained: Composition and Uses

Pipe dope, a thick, paste-like compound primarily composed of powdered fillers, oils, and resins, is designed to create airtight and watertight seals in threaded pipe joints. It serves multiple purposes such as lubricating threads to prevent galling, filling minor imperfections, and providing chemical resistance against various substances like water, gas, and oils. Widely used in plumbing and industrial applications, pipe dope ensures durable, leak-free connections where Teflon tape might be insufficient due to vibration or chemical exposure.

Key Differences Between Teflon Tape and Pipe Dope

Teflon tape, made from polytetrafluoroethylene, provides a non-adhesive, flexible seal ideal for threaded plumbing connections, preventing leaks by filling gaps without hardening. Pipe dope, a paste-like sealing compound, offers superior adhesion and fills irregular thread shapes, ensuring a durable, airtight seal especially useful for metal pipes under high pressure. The key differences lie in application ease, sealing strength, and suitability, with Teflon tape favored for quick fixes and pipe dope preferred for heavy-duty, long-lasting seals.

Application Techniques: How to Use Teflon Tape Properly

To apply Teflon tape properly, begin by cleaning the pipe threads to remove debris and moisture, ensuring a secure seal. Wrap the tape clockwise around the male threads, overlapping by about half the tape's width and covering 2-3 complete thread turns to prevent leaks. Avoid applying tape too thickly or crossing over the pipe end to ensure a tight, leak-free joint in plumbing or gas connections.

Proper Application: Pipe Dope Best Practices

Pipe dope, also known as pipe joint compound, should be applied evenly to the male threads of pipes to ensure a tight, leak-free seal. It is important to use an appropriate amount, avoiding excess that can contaminate the pipe interior or obstruct flow. Applying pipe dope according to manufacturer guidelines enhances joint durability and is especially effective for metal threaded connections under high pressure or temperature conditions.

Leak Prevention: Which Sealing Method Performs Best?

Teflon tape provides a reliable, non-adhesive seal by filling pipe thread gaps, effectively preventing leaks in plumbing connections under moderate pressure conditions. Pipe dope, or thread sealant, offers superior sealing performance in high-pressure or irregular thread applications by creating a more flexible, adhesive barrier that resists vibration and loosening. Studies indicate pipe dope tends to outperform Teflon tape in preventing leaks over extended periods, especially in gas lines or heavy-duty systems requiring maximum durability.

Compatibility with Pipe Materials: Teflon Tape vs Pipe Dope

Teflon tape, made from polytetrafluoroethylene (PTFE), offers excellent compatibility with metal pipes such as brass, steel, and copper due to its non-reactive and flexible nature. Pipe dope, a paste-like compound containing various lubricants and sealants, adapts well to a broader range of materials including metal, plastic, and threaded connections, providing durable sealing and preventing leaks. When selecting between Teflon tape and pipe dope, consider the specific pipe material and application environment to ensure optimal sealing performance and chemical resistance.

Safety and Chemical Resistance Comparison

Teflon tape offers superior chemical resistance, making it ideal for sealing pipes exposed to aggressive chemicals and high temperatures without degrading or leaking. Pipe dope provides excellent safety by creating a flexible, leak-proof seal that can accommodate pipe expansion and contraction but may contain volatile organic compounds posing health risks during application. Combining these materials strategically enhances durability and safety in plumbing systems by leveraging Teflon's inert properties and pipe dope's adhesive strength.

Cost Analysis: Teflon Tape vs Pipe Dope

Teflon tape generally offers a lower initial cost compared to pipe dope, making it a budget-friendly choice for both DIY and professional plumbing applications. Pipe dope, though often more expensive upfront, provides a stronger seal that can reduce the likelihood of costly leaks and maintenance over time. Evaluating long-term expenses and application requirements is crucial for an accurate cost analysis between these two pipe sealing options.

Choosing the Right Sealant: Expert Recommendations

Expert recommendations emphasize using Teflon tape for threaded plumbing connections requiring a clean, non-messy seal with moderate pressure tolerance. Pipe dope, also known as pipe thread sealant, is preferred for metal pipes exposed to high temperatures or pressures, offering superior lubrication and a stronger, more flexible seal. Selecting the appropriate sealant depends on pipe material, application conditions, and the need for ease of disassembly or long-term durability.

Teflon Tape vs Pipe Dope Infographic

materialdif.com

materialdif.com