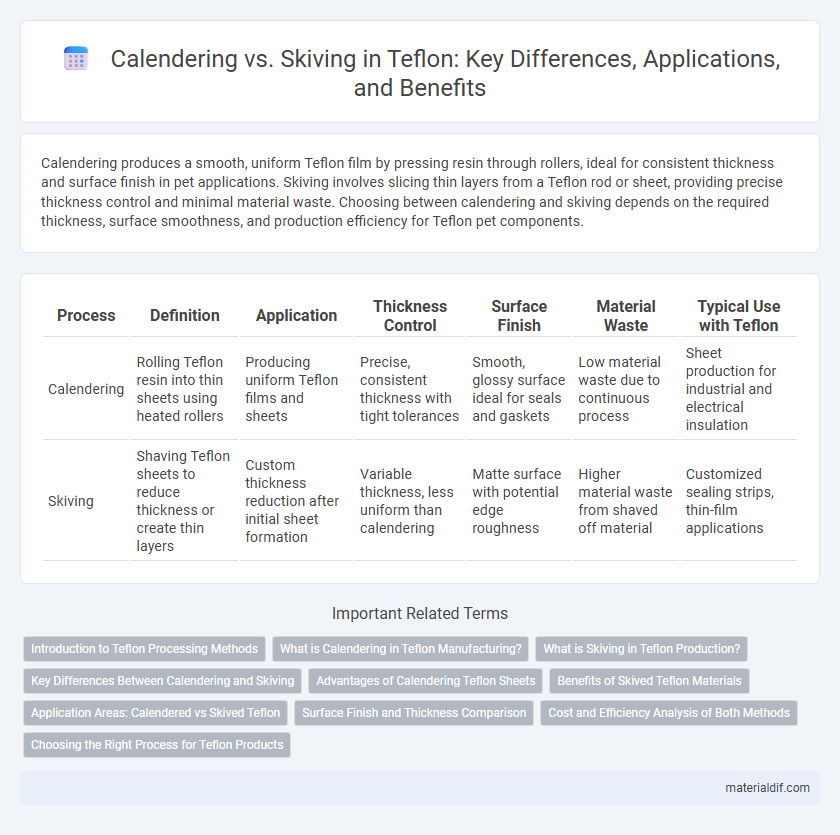

Calendering produces a smooth, uniform Teflon film by pressing resin through rollers, ideal for consistent thickness and surface finish in pet applications. Skiving involves slicing thin layers from a Teflon rod or sheet, providing precise thickness control and minimal material waste. Choosing between calendering and skiving depends on the required thickness, surface smoothness, and production efficiency for Teflon pet components.

Table of Comparison

| Process | Definition | Application | Thickness Control | Surface Finish | Material Waste | Typical Use with Teflon |

|---|---|---|---|---|---|---|

| Calendering | Rolling Teflon resin into thin sheets using heated rollers | Producing uniform Teflon films and sheets | Precise, consistent thickness with tight tolerances | Smooth, glossy surface ideal for seals and gaskets | Low material waste due to continuous process | Sheet production for industrial and electrical insulation |

| Skiving | Shaving Teflon sheets to reduce thickness or create thin layers | Custom thickness reduction after initial sheet formation | Variable thickness, less uniform than calendering | Matte surface with potential edge roughness | Higher material waste from shaved off material | Customized sealing strips, thin-film applications |

Introduction to Teflon Processing Methods

Calendering and skiving are two primary processing methods used in shaping Teflon (PTFE) materials for industrial applications. Calendering involves passing heated Teflon through rollers to produce thin films or sheets with uniform thickness and surface finish, ideal for gaskets and seals. Skiving, on the other hand, precisely slices PTFE rods or sheets into thin layers, enabling the manufacture of custom-fit components with tight tolerances for chemical resistance and low friction.

What is Calendering in Teflon Manufacturing?

Calendering in Teflon manufacturing is a process where heated Teflon resin is passed through a series of rollers to form thin, uniform sheets or films with precise thickness control. This method ensures consistent surface smoothness and enhanced mechanical properties, which are critical for applications requiring high durability and chemical resistance. Calendered Teflon sheets are commonly used in electrical insulation, gaskets, and non-stick coatings due to their superior dimensional stability and uniformity.

What is Skiving in Teflon Production?

Skiving in Teflon production involves precisely trimming or shaving the surface of polytetrafluoroethylene (PTFE) sheets or rods to achieve uniform thickness and smoothness. This process enhances the dimensional accuracy and surface finish, essential for high-performance applications in industries like electronics and aerospace. Skiving differs from calendering, which shapes PTFE by passing it through rollers, as skiving is a subtractive method ensuring precise customization of Teflon components.

Key Differences Between Calendering and Skiving

Calendering involves pressing Teflon resin through heated rollers to form thin, continuous sheets with uniform thickness, ideal for creating films and coatings. Skiving, on the other hand, is a precision cutting process that slices Teflon rods or sheets into thin films or tape with controlled thickness and smooth surfaces. Key differences include calendering's ability to produce large-scale sheets with consistent thickness, whereas skiving offers fine dimensional control and minimal material waste for specialized applications.

Advantages of Calendering Teflon Sheets

Calendering Teflon sheets offers precise control over thickness and surface finish, ensuring uniformity and consistency essential for high-performance applications. This process enables the production of smooth, thin films with superior mechanical properties compared to skiving, which involves slicing thicker blocks and may result in irregular thickness. Calendered sheets exhibit enhanced dimensional stability and can be manufactured in larger continuous rolls, optimizing material utilization and reducing waste.

Benefits of Skived Teflon Materials

Skived Teflon materials offer superior surface smoothness and tighter thickness tolerances compared to calendered alternatives, enhancing sealing performance in precision applications. The skiving process enables the production of thin, uniform films with consistent mechanical properties, which is critical for high-performance gaskets, seals, and insulation. This method also reduces material waste and improves dimensional accuracy, making it a cost-effective choice for specialized Teflon components.

Application Areas: Calendered vs Skived Teflon

Calendered Teflon films exhibit superior thickness uniformity and surface smoothness, making them ideal for applications in electrical insulation, gasketing, and high-performance laminates. Skived Teflon sheets, thinner and more flexible, are preferred in sealing, diaphragm, and insulation uses where conformability to complex shapes is critical. The choice between calendering and skiving directly impacts mechanical properties, dimensional tolerances, and suitability for specialized industries such as aerospace, electronics, and chemical processing.

Surface Finish and Thickness Comparison

Calendering of Teflon produces a smooth, uniform surface finish with controlled thickness typically ranging from 0.03 mm to 3 mm, ideal for thin films and sheets. Skiving yields slightly textured surfaces and allows precise control over thickness, often thicker than calendered sheets, suitable for gaskets and seals. Surface finish from calendering is generally more consistent, while skiving offers customization but may result in minor surface roughness.

Cost and Efficiency Analysis of Both Methods

Calendering Teflon involves passing the material through heated rollers, offering high production speed and consistent thickness, which reduces labor costs and enhances efficiency in large-scale manufacturing. Skiving Teflon, on the other hand, uses precision cutting for thinner, more intricate shapes but requires more time and specialized equipment, increasing operational expenses. Cost analysis indicates calendering is more economical for bulk production, while skiving offers efficiency in producing detailed components with lower material waste.

Choosing the Right Process for Teflon Products

Calendering offers precise thickness control and smooth surface finishes ideal for Teflon sheets and films used in industrial applications, while skiving excels in producing thinner, flexible Teflon films and tapes with uniform thickness. Selecting between calendering and skiving depends on the specific Teflon product requirements such as thickness tolerance, surface texture, and end-use flexibility. For high-volume manufacturing requiring consistent dimensions and enhanced mechanical properties, calendering is preferred; for custom or delicate applications requiring thin, flexible films, skiving provides superior control and minimal material waste.

Calendering vs Skiving Infographic

materialdif.com

materialdif.com