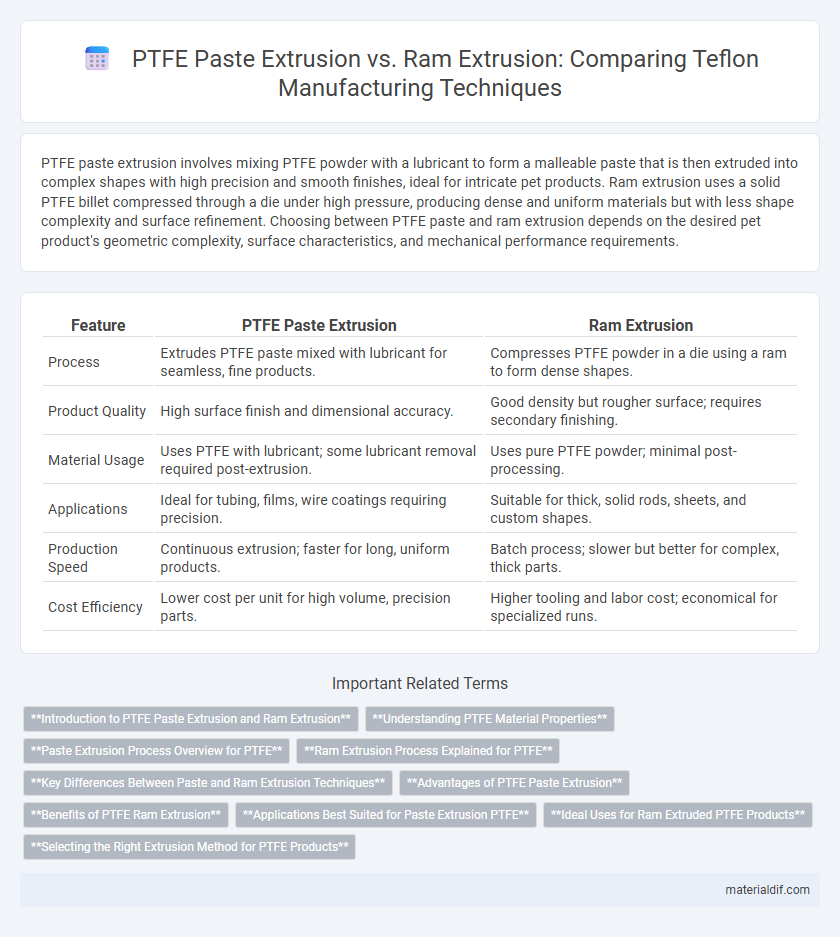

PTFE paste extrusion involves mixing PTFE powder with a lubricant to form a malleable paste that is then extruded into complex shapes with high precision and smooth finishes, ideal for intricate pet products. Ram extrusion uses a solid PTFE billet compressed through a die under high pressure, producing dense and uniform materials but with less shape complexity and surface refinement. Choosing between PTFE paste and ram extrusion depends on the desired pet product's geometric complexity, surface characteristics, and mechanical performance requirements.

Table of Comparison

| Feature | PTFE Paste Extrusion | Ram Extrusion |

|---|---|---|

| Process | Extrudes PTFE paste mixed with lubricant for seamless, fine products. | Compresses PTFE powder in a die using a ram to form dense shapes. |

| Product Quality | High surface finish and dimensional accuracy. | Good density but rougher surface; requires secondary finishing. |

| Material Usage | Uses PTFE with lubricant; some lubricant removal required post-extrusion. | Uses pure PTFE powder; minimal post-processing. |

| Applications | Ideal for tubing, films, wire coatings requiring precision. | Suitable for thick, solid rods, sheets, and custom shapes. |

| Production Speed | Continuous extrusion; faster for long, uniform products. | Batch process; slower but better for complex, thick parts. |

| Cost Efficiency | Lower cost per unit for high volume, precision parts. | Higher tooling and labor cost; economical for specialized runs. |

Introduction to PTFE Paste Extrusion and Ram Extrusion

PTFE paste extrusion involves mixing powdered PTFE with a lubricant to form a malleable paste, enabling the production of intricate shapes with fine detail and consistent density. Ram extrusion forces bulk PTFE material through a die using a piston, producing simpler, hollow, or solid profiles suitable for high-volume manufacturing. Both methods uniquely impact the mechanical properties and surface finish of PTFE products, influencing their suitability for various industrial applications.

Understanding PTFE Material Properties

PTFE material exhibits high chemical resistance, low friction, and excellent thermal stability, which significantly influence the choice between paste and ram extrusion methods. Paste extrusion allows for precise control of the polymer's viscosity and filler distribution, optimizing the microstructure and mechanical properties of the final product. Ram extrusion, by contrast, is more suited for producing dense, uniform PTFE parts due to its ability to apply consistent pressure, impacting the material's crystallinity and tensile strength.

Paste Extrusion Process Overview for PTFE

The paste extrusion process for PTFE involves mixing PTFE powder with a lubricant to form a malleable paste, which is then forced through a die to create various shapes and profiles. This method offers superior dimensional control and surface finish compared to ram extrusion by enabling continuous, uniform flow and precise shaping. Industrial applications often favor paste extrusion for complex PTFE components requiring consistency and tight tolerances.

Ram Extrusion Process Explained for PTFE

Ram extrusion for PTFE involves compressing powdered polytetrafluoroethylene inside a heated cylinder, forcing the material through a shaped die to form continuous, uniform profiles. This process ensures high density and excellent mechanical strength in the final extrudate due to the intense pressure applied by the ram piston. Ram extrusion is preferred for producing rods, tubes, and custom cross-sections where precise control over dimensions and material properties is critical.

Key Differences Between Paste and Ram Extrusion Techniques

PTFE paste extrusion involves mixing PTFE powder with a lubricant to create a malleable paste that is forced through a die, allowing intricate shapes and thin-walled components. Ram extrusion uses solid, compressed PTFE billets pushed directly through a die, resulting in higher density and superior mechanical strength in finished parts. The choice between paste and ram extrusion affects product precision, mechanical properties, and application suitability in industries like aerospace and chemical processing.

Advantages of PTFE Paste Extrusion

PTFE paste extrusion offers superior control over material density and uniformity, resulting in enhanced mechanical properties and reduced porosity compared to ram extrusion. This method enables the production of complex shapes with tighter tolerances and improved surface finishes, making it ideal for high-performance applications. The ability to consistently achieve fine microstructures in PTFE components contributes to better wear resistance and chemical inertness.

Benefits of PTFE Ram Extrusion

PTFE ram extrusion offers precise control over product density and uniformity, resulting in superior mechanical properties and enhanced chemical resistance. This method minimizes PTFE material waste and allows for the production of complex shapes with tight tolerances. Ram extrusion also improves the surface finish and reduces the need for secondary machining, increasing overall manufacturing efficiency.

Applications Best Suited for Paste Extrusion PTFE

Paste extrusion PTFE is best suited for producing intricate, thin-walled components such as films, membranes, and gaskets where superior dimensional control and surface finish are critical. This method excels in applications requiring high purity and chemical resistance, including semiconductor manufacturing, medical devices, and chemical processing equipment. Its ability to handle fine powders makes it ideal for complex shapes that demand exceptional mechanical properties and thermal stability.

Ideal Uses for Ram Extruded PTFE Products

Ram extruded PTFE products excel in applications requiring precise, high-strength shapes like rods, tubes, and custom profiles used in aerospace, chemical processing, and electrical insulation. The ram extrusion process ensures superior density and mechanical properties, ideal for components subjected to high stress and aggressive chemical environments. This method is preferred for manufacturing complex geometries with tight tolerances, enhancing performance in demanding industrial uses.

Selecting the Right Extrusion Method for PTFE Products

Selecting the right extrusion method for PTFE products depends on desired product characteristics and production scale, with paste extrusion offering superior control for fine, detailed shapes and ram extrusion excelling in producing larger, uniform parts. Paste extrusion uses a PTFE paste slurry providing enhanced precision and surface finish, while ram extrusion compacts PTFE powder into solid rods or tubes with higher throughput and mechanical strength. Understanding material requirements, dimensional tolerances, and end-use applications ensures optimal PTFE processing by matching extrusion techniques to performance criteria.

PTFE Paste Extrusion vs Ram Extrusion Infographic

materialdif.com

materialdif.com