Sintered Teflon offers superior mechanical strength and enhanced chemical resistance compared to Extruded Teflon, making it ideal for high-stress applications. Extruded Teflon provides consistent density and is easier to machine, which suits projects requiring precision and smooth finishes. Choosing between sintered and extruded Teflon depends on balancing durability with machining requirements for optimal performance in specialized environments.

Table of Comparison

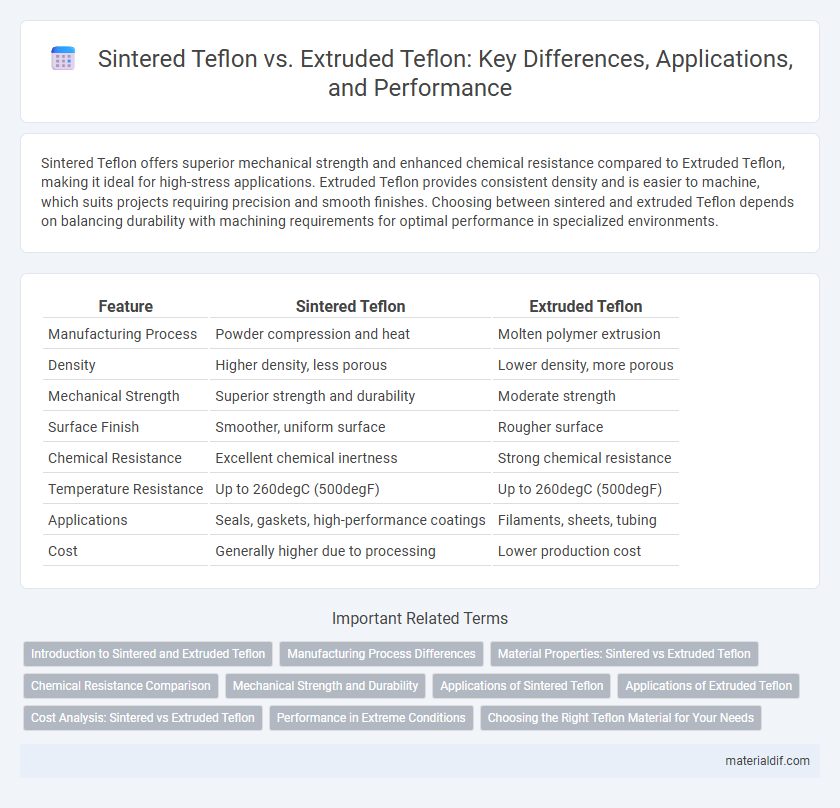

| Feature | Sintered Teflon | Extruded Teflon |

|---|---|---|

| Manufacturing Process | Powder compression and heat | Molten polymer extrusion |

| Density | Higher density, less porous | Lower density, more porous |

| Mechanical Strength | Superior strength and durability | Moderate strength |

| Surface Finish | Smoother, uniform surface | Rougher surface |

| Chemical Resistance | Excellent chemical inertness | Strong chemical resistance |

| Temperature Resistance | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Applications | Seals, gaskets, high-performance coatings | Filaments, sheets, tubing |

| Cost | Generally higher due to processing | Lower production cost |

Introduction to Sintered and Extruded Teflon

Sintered Teflon is created by compacting and heating PTFE powder below its melting point, resulting in a dense, porous structure ideal for filtration and bearing applications. Extruded Teflon is produced by forcing softened PTFE through a die, forming continuous sheets or rods with a smooth, non-porous surface suitable for seals and gaskets. Both processes influence the material's mechanical properties and chemical resistance, optimizing Teflon for specific industrial uses.

Manufacturing Process Differences

Sintered Teflon is produced by heating PTFE powder below its melting point, causing the particles to fuse into a solid mass without liquefying, resulting in a porous, high-strength material. Extruded Teflon is made by melting PTFE resin and forcing it through a die to form continuous shapes, yielding a denser, more uniform structure. The sintering process offers superior mechanical strength and wear resistance, while extrusion allows for precise dimensional control and smoother surface finishes.

Material Properties: Sintered vs Extruded Teflon

Sintered Teflon exhibits superior mechanical strength and enhanced chemical resistance compared to extruded Teflon due to its porous, compressed microstructure. Extruded Teflon offers more uniform density and better dimensional stability but lacks the robustness and wear resistance found in sintered forms. These differences make sintered Teflon ideal for high-performance seals and bearing applications, while extruded Teflon suits applications requiring precise tolerances and smooth finishes.

Chemical Resistance Comparison

Sintered Teflon exhibits superior chemical resistance compared to extruded Teflon due to its more uniform molecular structure, which reduces porosity and limits chemical permeation. The sintering process enhances structural integrity, making sintered Teflon more resistant to harsh acids, bases, and solvents. In contrast, extruded Teflon has slightly lower chemical resistance but often offers better mechanical strength and flexibility.

Mechanical Strength and Durability

Sintered Teflon exhibits superior mechanical strength and enhanced durability compared to extruded Teflon due to its denser molecular structure achieved through heat and pressure processing. The sintering process reduces porosity, resulting in improved resistance to wear, creep, and deformation under load, making it ideal for high-stress applications. Extruded Teflon, while more flexible and easier to form, generally offers lower mechanical strength and durability, limiting its use in demanding environments.

Applications of Sintered Teflon

Sintered Teflon is widely used in high-performance applications such as chemical processing equipment, seals, gaskets, and bearings due to its superior mechanical strength and enhanced chemical resistance. Its porous structure allows for better thermal stability and improved wear resistance, making it ideal for environments with extreme temperatures and aggressive chemicals. Industries including aerospace, automotive, and pharmaceuticals favor sintered Teflon for its durability and reliability under demanding conditions.

Applications of Extruded Teflon

Extruded Teflon is widely used in applications requiring consistent thickness and smooth surface finishes, such as gaskets, seals, and electrical insulation components. Its high chemical resistance and low friction make it ideal for automotive fuel system parts and industrial tubing. The material's excellent thermal stability supports use in food processing and pharmaceutical equipment where purity and non-reactivity are critical.

Cost Analysis: Sintered vs Extruded Teflon

Sintered Teflon typically incurs higher manufacturing costs due to its complex powder compression and heating process compared to extruded Teflon, which is produced by melting and shaping pellets. The enhanced mechanical properties and chemical resistance of sintered Teflon justify its price premium in demanding industrial applications. In contrast, extruded Teflon offers a cost-effective solution for less critical uses where flexibility and lower thermal stability are acceptable.

Performance in Extreme Conditions

Sintered Teflon exhibits superior performance in extreme conditions due to its enhanced density and uniform molecular structure, providing greater chemical resistance and higher thermal stability compared to extruded Teflon. Extruded Teflon, while more cost-effective, tends to have lower mechanical strength and may degrade faster under intense thermal and chemical exposure. The sintering process results in a material better suited for high-stress applications demanding exceptional durability and resistance.

Choosing the Right Teflon Material for Your Needs

Sintered Teflon offers superior mechanical strength and chemical resistance, making it ideal for demanding industrial applications requiring durability under high temperatures and aggressive chemicals. Extruded Teflon provides excellent flexibility and is typically used in applications needing tight dimensional tolerances and ease of machining. Selecting the right Teflon material depends on balancing factors like mechanical stress, environmental exposure, and precision requirements to optimize performance and longevity.

Sintered Teflon vs Extruded Teflon Infographic

materialdif.com

materialdif.com