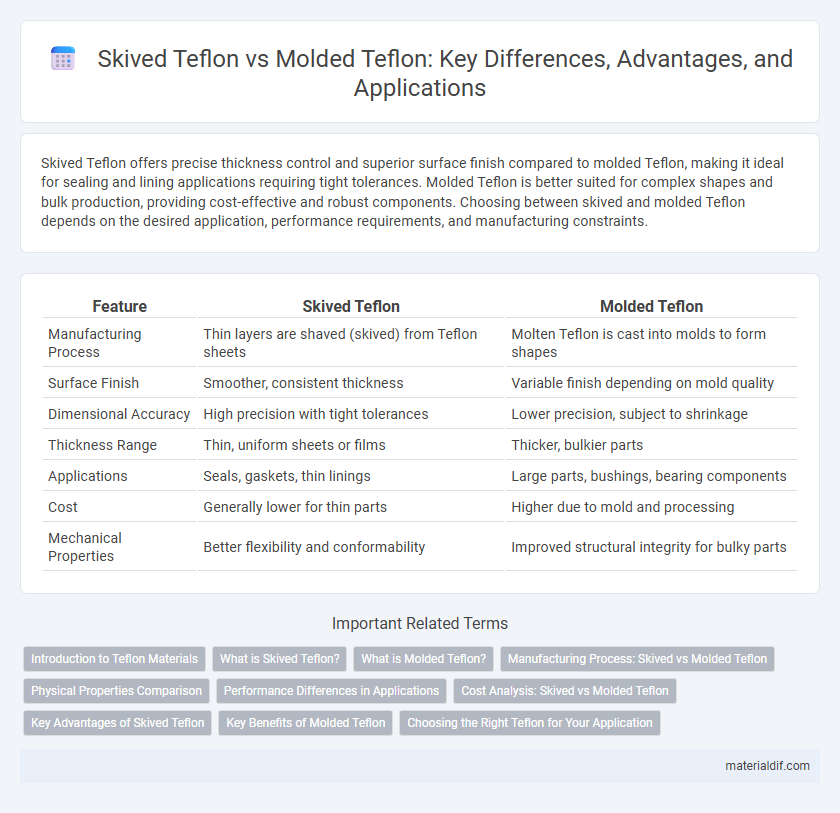

Skived Teflon offers precise thickness control and superior surface finish compared to molded Teflon, making it ideal for sealing and lining applications requiring tight tolerances. Molded Teflon is better suited for complex shapes and bulk production, providing cost-effective and robust components. Choosing between skived and molded Teflon depends on the desired application, performance requirements, and manufacturing constraints.

Table of Comparison

| Feature | Skived Teflon | Molded Teflon |

|---|---|---|

| Manufacturing Process | Thin layers are shaved (skived) from Teflon sheets | Molten Teflon is cast into molds to form shapes |

| Surface Finish | Smoother, consistent thickness | Variable finish depending on mold quality |

| Dimensional Accuracy | High precision with tight tolerances | Lower precision, subject to shrinkage |

| Thickness Range | Thin, uniform sheets or films | Thicker, bulkier parts |

| Applications | Seals, gaskets, thin linings | Large parts, bushings, bearing components |

| Cost | Generally lower for thin parts | Higher due to mold and processing |

| Mechanical Properties | Better flexibility and conformability | Improved structural integrity for bulky parts |

Introduction to Teflon Materials

Skived Teflon consists of thin sheets precisely sliced from expanded PTFE blocks, offering uniform thickness and a smooth finish ideal for sealing applications. Molded Teflon is formed by sintering PTFE powder into solid shapes, providing robust mechanical strength and complex geometries for industrial components. Both materials leverage PTFE's exceptional chemical resistance, low friction coefficient, and high temperature tolerance, making them essential in diverse manufacturing and engineering sectors.

What is Skived Teflon?

Skived Teflon is a thin, flexible sheet of polytetrafluoroethylene (PTFE) produced by slicing it from a block using a sharp blade, resulting in uniform thickness and smooth surfaces. This manufacturing process allows for precise control over thickness, making Skived Teflon ideal for high-performance sealing, gasket, and insulation applications. Skived Teflon's enhanced mechanical strength and minimal porosity distinguish it from Molded Teflon, which is formed by casting or compression molding.

What is Molded Teflon?

Molded Teflon refers to a fabrication process where polytetrafluoroethylene (PTFE) powder is compressed into a desired shape within a mold and then sintered at high temperatures to form a solid, seamless component. This method allows for the creation of complex geometries with excellent chemical resistance, low friction, and high-temperature stability inherent to PTFE material. Molded Teflon is commonly used in applications requiring durable, non-stick surfaces such as seals, gaskets, and insulating parts in chemical and electrical industries.

Manufacturing Process: Skived vs Molded Teflon

Skived Teflon is manufactured by extruding large sheets of PTFE, which are then shaved or "skived" into thin, uniform films with precise thickness control, enabling customized shapes and sizes. Molded Teflon involves compressing PTFE powder into a mold and sintering it to form complex, near-net shapes with less material waste and high dimensional stability. The skiving process offers smoother surface finishes ideal for sealing applications, while molding provides greater design flexibility for intricate components.

Physical Properties Comparison

Skived Teflon features a dense, uniform structure with excellent mechanical strength and flexibility, making it ideal for applications requiring tight tolerances and thin cross-sections. Molded Teflon tends to have a slightly less consistent density but offers superior chemical resistance and thermal stability due to its monolithic form. Both types exhibit low friction and high dielectric properties, but skived Teflon generally shows better dimensional stability under compression.

Performance Differences in Applications

Skived Teflon offers superior consistency in thickness and surface finish, making it ideal for applications requiring precise sealing and low friction, such as electrical insulation and gasket manufacturing. Molded Teflon provides enhanced structural integrity and higher mechanical strength, suitable for complex, high-wear components in chemical processing and food industry equipment. Performance differences largely depend on the application's need for dimensional accuracy versus durability under mechanical stress.

Cost Analysis: Skived vs Molded Teflon

Skived Teflon typically offers a lower cost per unit due to its manufacturing process, which involves slicing thin sheets from bulk Teflon stock, reducing raw material waste and production time. Molded Teflon requires higher initial setup costs for custom molds and often results in longer cycle times, making it more expensive for small to medium production runs. For large-scale applications, molded Teflon can be cost-effective due to repeatability and reduced post-processing, but skived Teflon remains preferable for budget-sensitive projects requiring thinner, precise components.

Key Advantages of Skived Teflon

Skived Teflon offers superior dimensional precision and uniform thickness compared to molded Teflon, enabling enhanced sealing and insulation performance in industrial applications. The mechanical skiving process produces a smooth, consistent surface free from voids, which improves chemical resistance and reduces friction more effectively. Its ability to be fabricated into complex shapes with tight tolerances makes skived Teflon ideal for high-performance gasketing, lining, and electrical insulation solutions.

Key Benefits of Molded Teflon

Molded Teflon offers superior durability and chemical resistance compared to skived Teflon, making it ideal for high-performance sealing applications in aggressive environments. Its seamless construction ensures uniform thickness and enhanced mechanical strength, reducing the risk of leaks and failure under pressure. Molded Teflon also provides excellent dimensional stability and can be custom-engineered to meet precise specifications for industrial use.

Choosing the Right Teflon for Your Application

Skived Teflon offers superior dimensional accuracy and smoother surface finishes, making it ideal for sealing applications requiring tight tolerances and low friction. Molded Teflon provides excellent chemical resistance and structural integrity, suitable for components subjected to harsh environments and higher mechanical stress. Selecting between skived and molded Teflon depends on factors such as application demands, thermal stability, and mechanical load requirements to ensure optimal performance and durability.

Skived Teflon vs Molded Teflon Infographic

materialdif.com

materialdif.com