FDA-approved Teflon ensures a higher standard of safety and quality, making it suitable for products that come into contact with pets. Non-FDA Teflon may contain harmful chemicals or impurities that pose health risks to animals, leading to potential toxicity or allergic reactions. Choosing FDA-approved Teflon guarantees compliance with strict regulatory guidelines, providing peace of mind for pet owners.

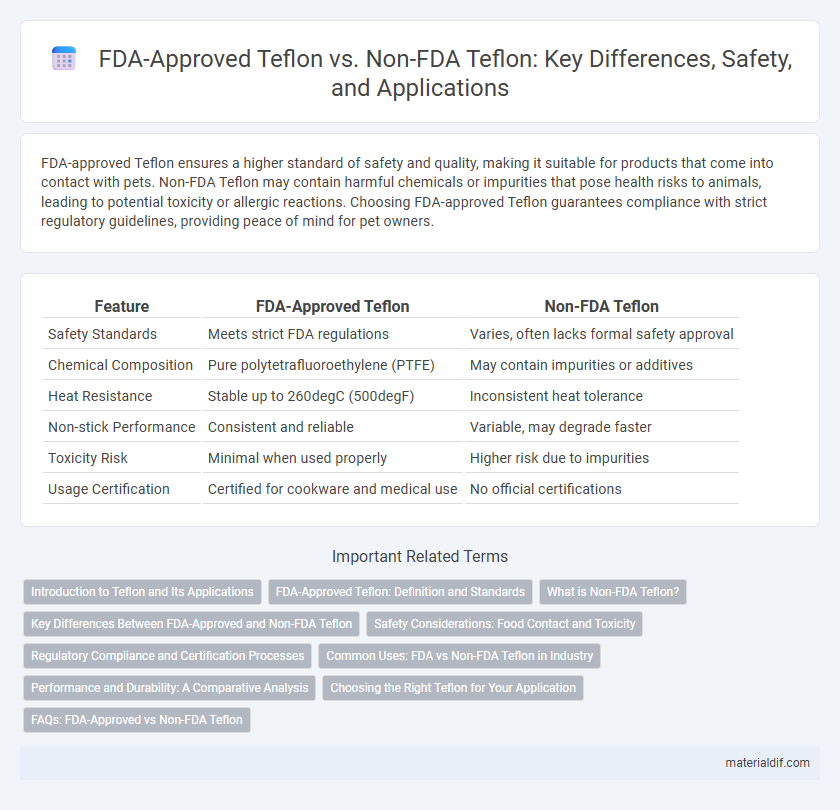

Table of Comparison

| Feature | FDA-Approved Teflon | Non-FDA Teflon |

|---|---|---|

| Safety Standards | Meets strict FDA regulations | Varies, often lacks formal safety approval |

| Chemical Composition | Pure polytetrafluoroethylene (PTFE) | May contain impurities or additives |

| Heat Resistance | Stable up to 260degC (500degF) | Inconsistent heat tolerance |

| Non-stick Performance | Consistent and reliable | Variable, may degrade faster |

| Toxicity Risk | Minimal when used properly | Higher risk due to impurities |

| Usage Certification | Certified for cookware and medical use | No official certifications |

Introduction to Teflon and Its Applications

Teflon, a brand name for polytetrafluoroethylene (PTFE), is widely used for its non-stick, chemical-resistant, and heat-resistant properties across cookware, industrial coatings, and electronics. FDA-approved Teflon meets strict safety and purity standards, ensuring its suitability for food-contact applications such as non-stick pans and food processing equipment. Non-FDA Teflon lacks these certifications, making it unsuitable for cookware and increasing the risk of harmful chemical exposure during food preparation.

FDA-Approved Teflon: Definition and Standards

FDA-approved Teflon refers to polytetrafluoroethylene (PTFE) materials that meet strict safety and quality standards established by the U.S. Food and Drug Administration for use in food contact applications. These standards ensure the chemical stability, non-toxicity, and resistance to high temperatures, preventing harmful substances from leaching into food during cooking or processing. Compliance with FDA regulations guarantees that the Teflon coating is safe for consumer use in cookware and food packaging.

What is Non-FDA Teflon?

Non-FDA Teflon refers to polytetrafluoroethylene (PTFE) coatings that have not met the strict safety and regulatory standards set by the U.S. Food and Drug Administration for food contact applications. These coatings may contain higher levels of impurities or manufacturing residues that could pose health risks when used in cookware or food processing equipment. Without FDA approval, Non-FDA Teflon lacks verified safety certifications, making it unsuitable for direct food contact and increasing potential exposure to harmful substances.

Key Differences Between FDA-Approved and Non-FDA Teflon

FDA-approved Teflon undergoes rigorous testing to meet strict safety and non-toxicity standards set by the U.S. Food and Drug Administration, ensuring it is safe for food contact and medical applications. Non-FDA Teflon may lack proper certification, potentially containing harmful substances or lower-quality materials that pose health risks during use. Key differences include chemical composition, durability, and regulatory compliance, which directly impact product safety and performance in consumer and industrial settings.

Safety Considerations: Food Contact and Toxicity

FDA-approved Teflon coatings are rigorously tested to ensure non-toxicity and safe contact with food, meeting strict regulatory standards that limit the release of harmful chemicals such as perfluorooctanoic acid (PFOA). Non-FDA Teflon products may contain higher levels of unregulated substances, posing potential risks of chemical leaching and toxicity when exposed to high temperatures during cooking. Choosing FDA-approved Teflon reduces the likelihood of adverse health effects and ensures compliance with food safety guidelines.

Regulatory Compliance and Certification Processes

FDA-approved Teflon undergoes stringent regulatory compliance and certification processes to ensure it meets rigorous safety standards for food contact applications, including detailed evaluations of chemical composition and potential migration risks. Non-FDA Teflon lacks these certifications, posing potential health risks due to unverified manufacturing practices and unknown chemical additives. Certification ensures traceability, consistent quality control, and adherence to FDA guidelines, making FDA-approved Teflon the preferred choice for safe and legally compliant cookware and food packaging materials.

Common Uses: FDA vs Non-FDA Teflon in Industry

FDA-approved Teflon is widely used in medical devices, food processing equipment, and cookware due to its safety and non-toxicity, ensuring compliance with stringent health regulations. Non-FDA Teflon finds applications in industrial sectors such as automotive, electronics, and chemical manufacturing where regulatory safety for human contact is less critical. The distinction between FDA and non-FDA Teflon primarily revolves around usage environments, with FDA-approved variants prioritized for direct food and medical contact.

Performance and Durability: A Comparative Analysis

FDA-approved Teflon coatings exhibit superior performance and durability due to rigorous testing and compliance with safety standards, ensuring resistance to high temperatures and chemical corrosion, which prolongs the lifespan of cookware and industrial applications. Non-FDA Teflon variants often lack standardized manufacturing processes, leading to inconsistent quality, reduced non-stick effectiveness, and increased susceptibility to peeling or degradation under stress. Performance metrics such as thermal stability and abrasion resistance are significantly higher in FDA-approved Teflon products, making them a preferred choice for both consumer safety and long-term durability.

Choosing the Right Teflon for Your Application

FDA-approved Teflon meets strict regulatory standards for food safety and chemical resistance, making it ideal for cookware and food processing applications, while non-FDA Teflon may be suitable for industrial uses that do not involve direct food contact. Selecting the right Teflon requires evaluating factors such as temperature tolerance, chemical exposure, and safety requirements specific to the application. Ensuring FDA approval guarantees compliance with health regulations, minimizing risks of contamination and material degradation in food-related environments.

FAQs: FDA-Approved vs Non-FDA Teflon

FDA-approved Teflon undergoes rigorous testing to ensure it meets strict safety and toxicity standards set by the U.S. Food and Drug Administration, making it suitable for use in cookware and medical devices. Non-FDA Teflon may not comply with these regulations, potentially exposing users to harmful chemicals such as perfluorooctanoic acid (PFOA), which has been linked to health risks. Consumers should prioritize FDA-approved Teflon products to guarantee non-toxicity, durability, and reliable non-stick performance.

FDA-approved Teflon vs Non-FDA Teflon Infographic

materialdif.com

materialdif.com