Teflon bearings offer low friction and excellent chemical resistance, making them ideal for applications requiring smooth motion without lubrication. Bronze bearings provide superior strength and durability under heavy loads but require regular lubrication to prevent wear and corrosion. Choosing between Teflon and bronze bearings depends on the specific operating conditions, load requirements, and maintenance capabilities of the pet equipment.

Table of Comparison

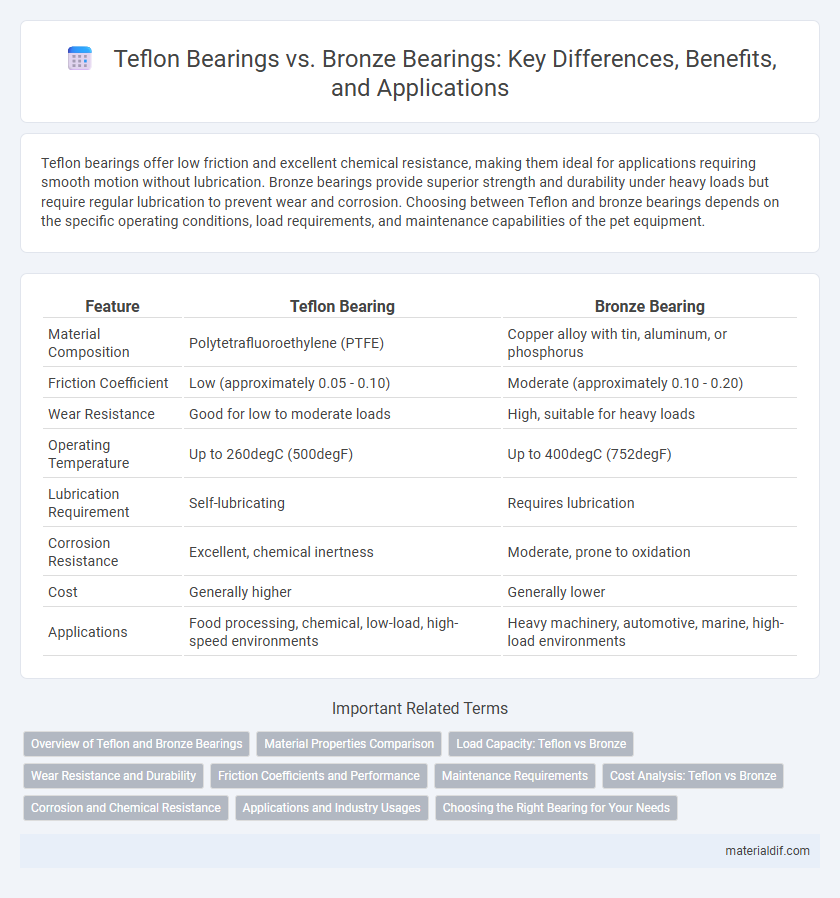

| Feature | Teflon Bearing | Bronze Bearing |

|---|---|---|

| Material Composition | Polytetrafluoroethylene (PTFE) | Copper alloy with tin, aluminum, or phosphorus |

| Friction Coefficient | Low (approximately 0.05 - 0.10) | Moderate (approximately 0.10 - 0.20) |

| Wear Resistance | Good for low to moderate loads | High, suitable for heavy loads |

| Operating Temperature | Up to 260degC (500degF) | Up to 400degC (752degF) |

| Lubrication Requirement | Self-lubricating | Requires lubrication |

| Corrosion Resistance | Excellent, chemical inertness | Moderate, prone to oxidation |

| Cost | Generally higher | Generally lower |

| Applications | Food processing, chemical, low-load, high-speed environments | Heavy machinery, automotive, marine, high-load environments |

Overview of Teflon and Bronze Bearings

Teflon bearings consist of polytetrafluoroethylene (PTFE), known for their excellent chemical resistance, low friction coefficient, and self-lubricating properties, making them ideal for applications requiring minimal maintenance and smooth motion. Bronze bearings, made from copper alloys with tin, aluminum, or silicon, provide high load capacity, durability, and superior wear resistance, often used in heavy-load and high-temperature environments. The choice between Teflon and bronze bearings depends on operational conditions, including load, speed, temperature, and the need for lubrication.

Material Properties Comparison

Teflon bearings offer superior chemical resistance and low friction due to their non-stick polytetrafluoroethylene (PTFE) composition, making them ideal for corrosive environments and applications requiring minimal lubrication. Bronze bearings, made from copper alloys with added elements like tin or lead, provide higher load capacity and better thermal conductivity, supporting heavy-duty mechanical stress and heat dissipation. The choice between Teflon and bronze bearings depends on the required balance of wear resistance, operating temperature range, and exposure to corrosive substances.

Load Capacity: Teflon vs Bronze

Teflon bearings offer low friction and excellent chemical resistance but generally have a lower load capacity compared to bronze bearings, which are known for their high strength and superior load-bearing capabilities. Bronze bearings can withstand higher radial and axial loads due to their metal composition and structural integrity, making them suitable for heavy-duty applications. Teflon bearings perform well under moderate loads with quieter operation and better corrosion resistance, but they are less durable under extreme pressures compared to bronze counterparts.

Wear Resistance and Durability

Teflon bearings exhibit superior wear resistance due to their low friction coefficient and self-lubricating properties, resulting in extended durability under low to moderate load conditions. Bronze bearings offer higher load-bearing capacity and toughness, making them more durable in heavy-duty applications where mechanical stress and impact are prevalent. Selecting between Teflon and bronze bearings depends on balancing the need for low friction and wear resistance against the requirement for strength and load endurance in specific industrial environments.

Friction Coefficients and Performance

Teflon bearings exhibit a significantly lower friction coefficient, typically around 0.05 to 0.1, compared to bronze bearings which range from 0.2 to 0.35, resulting in reduced wear and improved energy efficiency. The self-lubricating properties of Teflon enhance performance in low-load and low-speed applications by minimizing maintenance requirements and increasing service life. In contrast, bronze bearings offer higher load capacity and durability under heavy loads but require regular lubrication to maintain optimal performance.

Maintenance Requirements

Teflon bearings require minimal maintenance due to their self-lubricating properties, significantly reducing the need for regular lubrication and cleaning compared to bronze bearings. Bronze bearings demand frequent lubrication and inspections to prevent wear and corrosion, increasing overall maintenance efforts. The low friction and corrosion resistance of Teflon bearings enhance their durability, making them ideal for applications with limited access or harsh environments.

Cost Analysis: Teflon vs Bronze

Teflon bearings generally have a lower initial cost compared to bronze bearings due to cheaper raw materials and simpler manufacturing processes. Bronze bearings often incur higher expenses related to machining and maintenance, but their durability can reduce long-term replacement costs. Evaluating total cost of ownership favors Teflon in low-load applications, while bronze may be more cost-effective in heavy-duty environments demanding strength and wear resistance.

Corrosion and Chemical Resistance

Teflon bearings exhibit superior corrosion and chemical resistance compared to bronze bearings, making them ideal for use in highly corrosive environments such as chemical processing and marine applications. Bronze bearings, while durable and strong, are more susceptible to oxidation and chemical degradation when exposed to aggressive chemicals or saltwater. The non-reactive nature of Teflon reduces maintenance needs and extends bearing lifespan in harsh conditions where bronze would typically require frequent replacement.

Applications and Industry Usages

Teflon bearings excel in applications requiring low friction, chemical resistance, and minimal maintenance, commonly used in food processing, pharmaceuticals, and electronics industries. Bronze bearings offer superior load capacity and durability, making them ideal for heavy machinery, automotive, and industrial equipment sectors. Both materials serve distinct roles, with Teflon preferred for clean, low-wear environments and bronze favored for high-stress, high-temperature conditions.

Choosing the Right Bearing for Your Needs

Teflon bearings offer low friction, excellent chemical resistance, and self-lubricating properties, making them ideal for applications requiring minimal maintenance and smooth operation in corrosive environments. Bronze bearings provide superior load-carrying capacity and durability, commonly used in heavy-duty machinery where high strength and resistance to wear are crucial. Choosing the right bearing depends on factors such as load requirements, environmental conditions, maintenance frequency, and cost considerations to ensure optimal performance and longevity.

Teflon Bearing vs Bronze Bearing Infographic

materialdif.com

materialdif.com