Reinforced Teflon offers enhanced durability and resistance to wear compared to unreinforced Teflon, making it ideal for high-stress applications. Its improved mechanical strength helps prevent cracking and deformation under heavy loads or extreme temperatures. Unreinforced Teflon, while providing excellent chemical resistance and low friction, is more prone to damage in demanding environments.

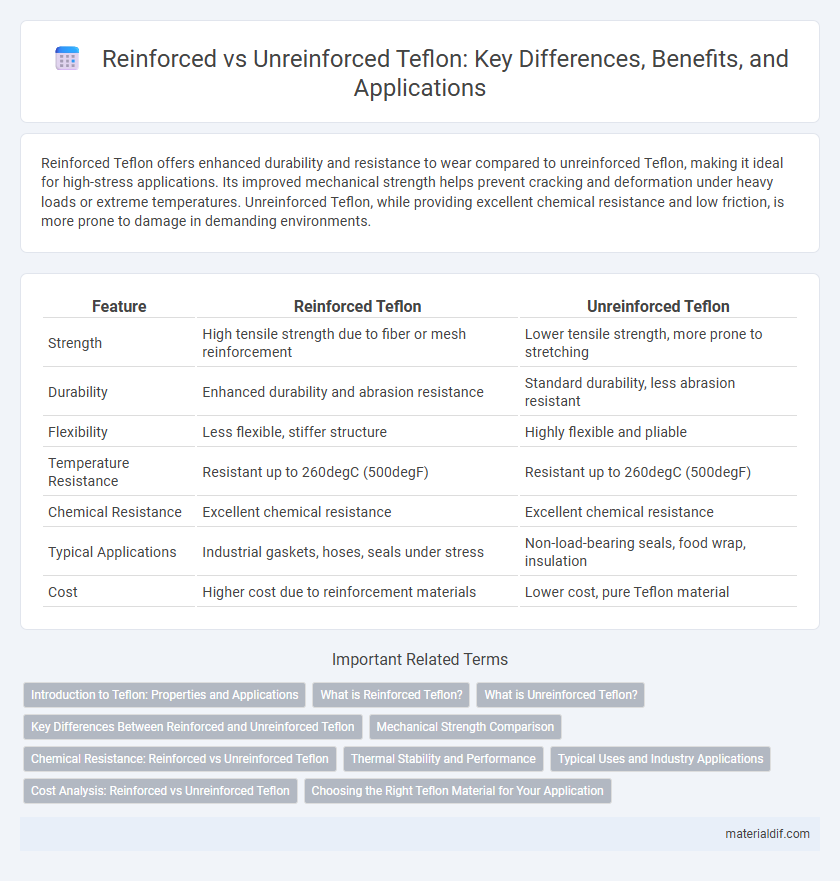

Table of Comparison

| Feature | Reinforced Teflon | Unreinforced Teflon |

|---|---|---|

| Strength | High tensile strength due to fiber or mesh reinforcement | Lower tensile strength, more prone to stretching |

| Durability | Enhanced durability and abrasion resistance | Standard durability, less abrasion resistant |

| Flexibility | Less flexible, stiffer structure | Highly flexible and pliable |

| Temperature Resistance | Resistant up to 260degC (500degF) | Resistant up to 260degC (500degF) |

| Chemical Resistance | Excellent chemical resistance | Excellent chemical resistance |

| Typical Applications | Industrial gaskets, hoses, seals under stress | Non-load-bearing seals, food wrap, insulation |

| Cost | Higher cost due to reinforcement materials | Lower cost, pure Teflon material |

Introduction to Teflon: Properties and Applications

Reinforced Teflon incorporates glass fibers or other fillers to enhance mechanical strength, wear resistance, and dimensional stability compared to unreinforced Teflon, which is pure polytetrafluoroethylene (PTFE) known for its excellent chemical resistance, low friction, and high-temperature tolerance. These enhancements make reinforced Teflon ideal for demanding industrial applications such as seals, bearings, and gaskets, where improved load-bearing capacity is essential. Unreinforced Teflon remains preferred in applications requiring maximum chemical inertness and flexibility, like non-stick cookware coatings and medical tubing.

What is Reinforced Teflon?

Reinforced Teflon is a composite material in which polytetrafluoroethylene (PTFE) is combined with fibrous or particulate fillers like glass, carbon, or bronze to enhance mechanical strength and wear resistance. This reinforcement improves dimensional stability, reduces creep, and increases load-bearing capacity compared to unreinforced Teflon, which consists solely of pure PTFE. As a result, reinforced Teflon is preferred in demanding applications such as seals, bearings, and gaskets requiring superior durability and performance under mechanical stress.

What is Unreinforced Teflon?

Unreinforced Teflon, also known as pure PTFE (polytetrafluoroethylene), is a versatile fluoropolymer characterized by its exceptional chemical resistance, low friction, and non-stick properties. Unlike reinforced Teflon, it contains no fillers or additives, resulting in superior purity but lower mechanical strength and abrasion resistance. Commonly used in applications requiring high temperature tolerance and inertness, unreinforced Teflon excels in sealing, lining, and coating functions where chemical inertness is critical.

Key Differences Between Reinforced and Unreinforced Teflon

Reinforced Teflon contains additives like glass fibers or carbon to enhance mechanical strength, wear resistance, and dimensional stability, while unreinforced Teflon remains pure polytetrafluoroethylene (PTFE) with superior chemical resistance and low friction. Reinforced variants exhibit higher load-bearing capacity and reduced deformation under stress, making them suitable for demanding industrial applications, unlike unreinforced Teflon which excels in applications requiring flexibility and high chemical inertness. Thermal expansion rates differ significantly as reinforced Teflon offers improved dimensional control compared to the higher thermal expansion of unreinforced Teflon.

Mechanical Strength Comparison

Reinforced Teflon exhibits significantly higher mechanical strength compared to unreinforced Teflon, thanks to the integration of glass fibers or carbon fibers that enhance its tensile and impact resistance. The reinforcement improves wear resistance and dimensional stability, making it suitable for demanding applications involving heavy loads or friction. Unreinforced Teflon, while offering excellent chemical resistance and low friction, lacks the durability and mechanical toughness necessary for high-stress environments.

Chemical Resistance: Reinforced vs Unreinforced Teflon

Reinforced Teflon exhibits enhanced chemical resistance due to its composite structure, which integrates fillers like glass or carbon fibers to improve mechanical strength while maintaining excellent inertness to corrosive substances. Unreinforced Teflon offers superior pure chemical resistance in highly aggressive environments but lacks the structural reinforcement necessary for applications involving high stress or abrasion. The choice between reinforced and unreinforced Teflon depends on balancing the need for chemical inertness with improved durability and mechanical performance in industrial applications.

Thermal Stability and Performance

Reinforced Teflon incorporates fillers such as glass fibers or carbon, significantly enhancing its thermal stability and mechanical performance compared to unreinforced Teflon, which typically has a native continuous service temperature of up to 260degC (500degF). The reinforcement improves dimensional stability and resistance to creep at elevated temperatures, making it suitable for high-stress applications in aerospace, automotive, and industrial machinery. Unreinforced Teflon offers excellent chemical resistance and low friction but is more prone to deformation and wear under thermal cycling and mechanical load.

Typical Uses and Industry Applications

Reinforced Teflon is commonly used in high-stress industrial applications such as chemical processing, aerospace, and automotive sectors where enhanced mechanical strength and thermal resistance are critical. Unreinforced Teflon finds typical use in food processing, electrical insulation, and non-stick cookware due to its excellent chemical inertness and low friction properties. Industries prioritize reinforced variants for durability under pressure and unreinforced forms for flexible, corrosion-resistant components.

Cost Analysis: Reinforced vs Unreinforced Teflon

Reinforced Teflon typically incurs higher initial costs due to the addition of materials like glass fiber or carbon fiber, which enhance its mechanical strength and durability. Unreinforced Teflon, while more cost-effective upfront, may require more frequent replacement or maintenance in demanding applications, leading to higher long-term expenses. Evaluating the total cost of ownership involves balancing initial investment against lifespan and performance requirements in specific industrial environments.

Choosing the Right Teflon Material for Your Application

Reinforced Teflon offers enhanced mechanical strength and improved wear resistance, making it ideal for applications involving high stress or dynamic loads. Unreinforced Teflon provides excellent chemical resistance and superior non-stick properties, suitable for environments requiring maximum purity and low friction. Selecting the right Teflon material depends on balancing the need for durability against chemical inertness and friction performance in your specific application.

Reinforced Teflon vs Unreinforced Teflon Infographic

materialdif.com

materialdif.com