Porous PTFE offers enhanced breathability and flexibility, making it ideal for filtration and medical applications requiring fluid or gas transfer. Dense PTFE provides superior chemical resistance, high mechanical strength, and excellent sealing properties, suitable for harsh environments and industrial uses. Selecting between porous and dense PTFE depends on the balance needed between permeability and durability in specific pet-related applications.

Table of Comparison

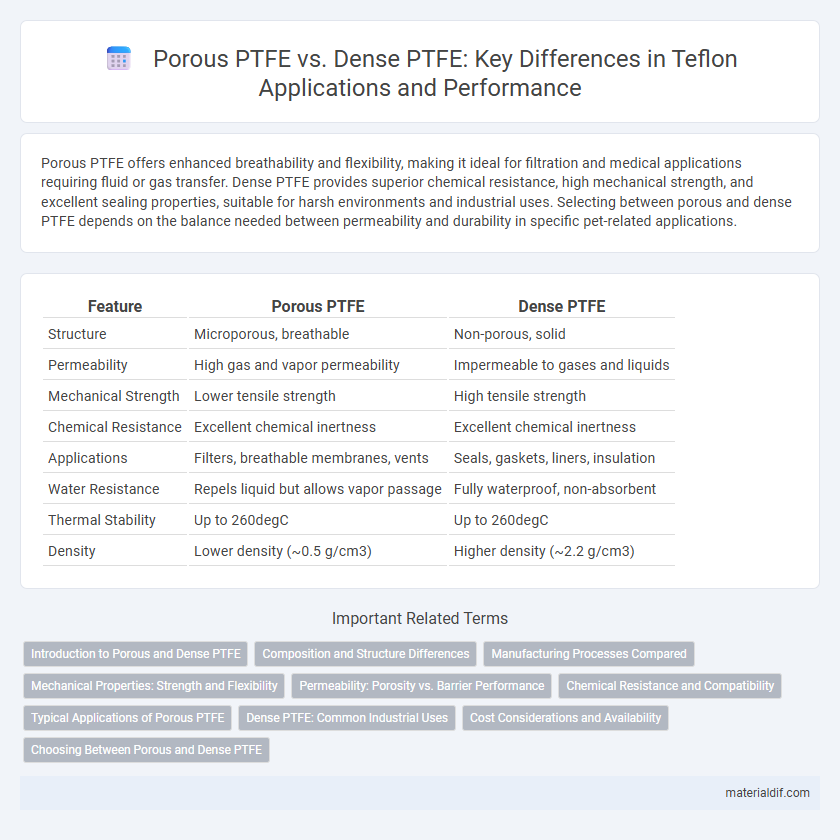

| Feature | Porous PTFE | Dense PTFE |

|---|---|---|

| Structure | Microporous, breathable | Non-porous, solid |

| Permeability | High gas and vapor permeability | Impermeable to gases and liquids |

| Mechanical Strength | Lower tensile strength | High tensile strength |

| Chemical Resistance | Excellent chemical inertness | Excellent chemical inertness |

| Applications | Filters, breathable membranes, vents | Seals, gaskets, liners, insulation |

| Water Resistance | Repels liquid but allows vapor passage | Fully waterproof, non-absorbent |

| Thermal Stability | Up to 260degC | Up to 260degC |

| Density | Lower density (~0.5 g/cm3) | Higher density (~2.2 g/cm3) |

Introduction to Porous and Dense PTFE

Porous PTFE features a network of microscopic pores providing exceptional breathability and filtration capabilities, ideal for applications requiring fluid permeability and chemical resistance. Dense PTFE, characterized by its non-porous, solid structure, offers superior mechanical strength, impermeability, and excellent resistance to extreme temperatures and corrosive environments. Both forms of PTFE leverage polytetrafluoroethylene's inherent chemical inertness, with porous PTFE widely used in gasketing and filtration, and dense PTFE favored in sealing and insulation applications.

Composition and Structure Differences

Porous PTFE consists of a network of interconnected voids formed during the expansion process, resulting in a microporous structure that enhances permeability and flexibility. Dense PTFE is produced through compression molding and sintering, yielding a solid, non-porous material with high chemical resistance and mechanical strength. The primary difference in composition lies in the void fraction present in porous PTFE, which significantly affects its physical properties compared to the fully compacted, crystallized dense PTFE.

Manufacturing Processes Compared

Porous PTFE is manufactured through a process of stretching the polymer, creating a network of microscopic voids that enhance filtration and breathability, while dense PTFE undergoes sintering without stretching, resulting in a compact, non-porous structure ideal for chemical resistance and insulation. The stretching step in porous PTFE involves biaxial expansion at controlled temperatures, which aligns polymer chains and forms the characteristic microporous structure. Dense PTFE's manufacturing focuses on high-pressure molding and sintering, yielding superior mechanical strength and minimal permeability compared to porous variants.

Mechanical Properties: Strength and Flexibility

Porous PTFE exhibits enhanced flexibility due to its microstructure, allowing better deformation under stress but with lower tensile strength compared to dense PTFE. Dense PTFE offers superior mechanical strength and rigidity, making it ideal for applications requiring high durability and resistance to mechanical wear. The choice between porous and dense PTFE depends on the balance needed between strength and flexibility in specific engineering applications.

Permeability: Porosity vs. Barrier Performance

Porous PTFE offers high permeability due to its interconnected pore structure, enabling efficient filtration and breathability in applications like gas separation and medical implants. Dense PTFE, characterized by its non-porous matrix, provides superior barrier performance, effectively blocking liquids, gases, and chemicals for use in gasketing and protective linings. The choice between porous and dense PTFE depends on the required balance between permeability for fluid or gas flow and impermeability for sealing and insulation purposes.

Chemical Resistance and Compatibility

Porous PTFE exhibits enhanced chemical resistance due to its microporous structure, allowing it to withstand aggressive solvents and corrosive chemicals more effectively than dense PTFE. Dense PTFE offers excellent chemical compatibility with a wide range of substances, providing a non-reactive surface that resists almost all acids, bases, and solvents with minimal permeation. Both forms maintain superior resistance to chemical degradation, but porous PTFE is preferred in applications requiring filtration and diffusion alongside chemical durability.

Typical Applications of Porous PTFE

Porous PTFE is widely used in filtration systems, gas diffusion layers in fuel cells, and medical implants due to its unique microstructure that allows fluid or gas passage while providing chemical resistance and biocompatibility. It serves crucial roles in breathable membranes for protective clothing and venting solutions for electronic enclosures, leveraging its ability to block liquids yet permit air flow. Dense PTFE, in contrast, is primarily utilized for gaskets, seals, and insulation where impermeability and mechanical strength are essential.

Dense PTFE: Common Industrial Uses

Dense PTFE, characterized by its non-porous structure, is widely used in industrial applications requiring exceptional chemical resistance and low friction, such as gaskets, seals, and valve parts. Its impermeability to gases and liquids makes it ideal for fluid handling systems, preventing leaks and contamination. Dense PTFE also excels in electrical insulation, serving critical roles in wiring and cable coatings within harsh environments.

Cost Considerations and Availability

Porous PTFE typically incurs higher manufacturing costs due to its specialized microporous structure, leading to limited availability compared to dense PTFE, which is produced in larger volumes at a lower cost. Dense PTFE's widespread industrial use ensures better market availability and cost-effectiveness for applications requiring standard chemical resistance and low friction. Budget-sensitive projects often opt for dense PTFE, while porous PTFE is reserved for advanced filtration or medical uses where performance justifies the premium price.

Choosing Between Porous and Dense PTFE

Porous PTFE offers superior breathability and chemical resistance, making it ideal for applications requiring filtration or venting, while dense PTFE provides enhanced mechanical strength and impermeability suited for seals and gaskets in harsh environments. Selecting between porous and dense PTFE depends on specific performance requirements such as permeability, durability, and environmental exposure. Evaluating factors like fluid flow, pressure resistance, and temperature tolerance ensures optimal material choice for industrial or medical uses.

Porous PTFE vs Dense PTFE Infographic

materialdif.com

materialdif.com