Teflon coating applies a thin layer of non-stick material to the surface of pet products, providing a smooth, easy-to-clean finish that resists stains and odors. Teflon lining, on the other hand, involves integrating the Teflon material into the inner layers, offering enhanced durability and long-lasting protection against wear and tear. Choosing between Teflon coating and lining depends on the specific pet item's usage, with lining generally preferred for high-contact areas requiring extensive resistance.

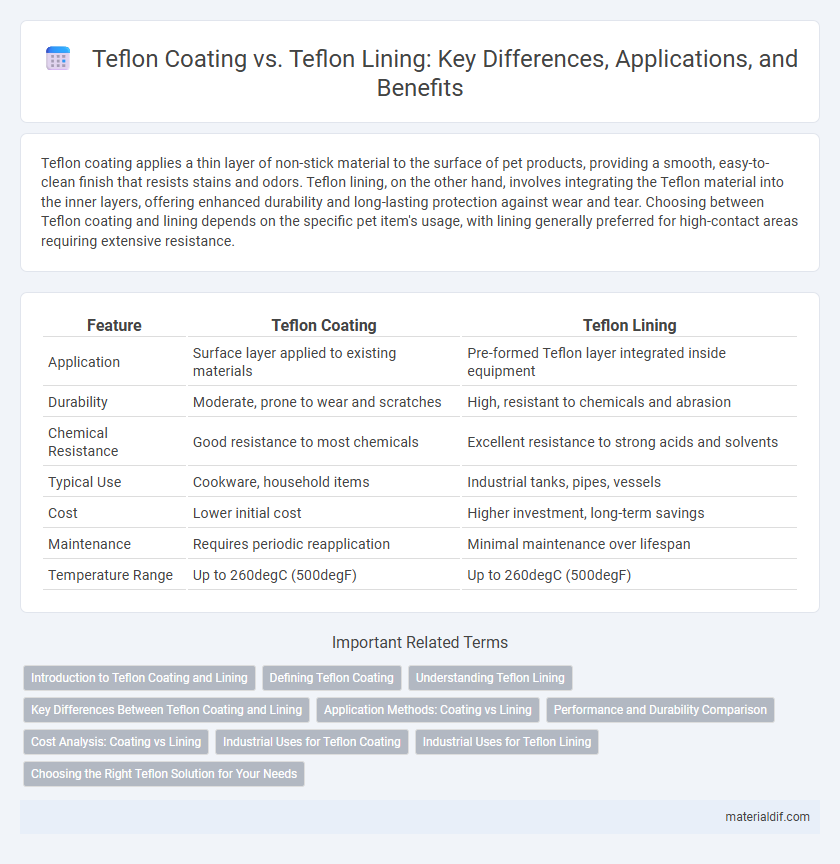

Table of Comparison

| Feature | Teflon Coating | Teflon Lining |

|---|---|---|

| Application | Surface layer applied to existing materials | Pre-formed Teflon layer integrated inside equipment |

| Durability | Moderate, prone to wear and scratches | High, resistant to chemicals and abrasion |

| Chemical Resistance | Good resistance to most chemicals | Excellent resistance to strong acids and solvents |

| Typical Use | Cookware, household items | Industrial tanks, pipes, vessels |

| Cost | Lower initial cost | Higher investment, long-term savings |

| Maintenance | Requires periodic reapplication | Minimal maintenance over lifespan |

| Temperature Range | Up to 260degC (500degF) | Up to 260degC (500degF) |

Introduction to Teflon Coating and Lining

Teflon coating involves applying a thin layer of polytetrafluoroethylene (PTFE) on surfaces to provide non-stick, anti-corrosive, and low-friction properties commonly used in cookware and industrial equipment. Teflon lining refers to a thicker, molded layer of PTFE applied inside pipes, tanks, and vessels to protect against chemical corrosion and wear in harsh environments. Both Teflon coating and lining enhance durability and chemical resistance but differ significantly in application thickness and industrial use cases.

Defining Teflon Coating

Teflon coating refers to a thin, non-stick layer of polytetrafluoroethylene (PTFE) applied to surfaces such as cookware to reduce friction and prevent food from sticking. This surface treatment is commonly used in kitchen appliances, industrial machinery, and automotive parts due to its chemical resistance and heat tolerance up to approximately 260degC (500degF). Unlike Teflon lining, which involves thicker and more durable PTFE layers for protective barrier applications in pipes and tanks, Teflon coating primarily enhances usability and ease of cleaning on consumer products.

Understanding Teflon Lining

Teflon lining refers to the application of a durable, chemically inert polytetrafluoroethylene (PTFE) layer inside vessels, pipes, or equipment to prevent corrosion and chemical reactions with aggressive substances. Unlike Teflon coating, which is typically a thinner surface application on cookware or tools, Teflon lining provides enhanced protection against harsh industrial environments by forming a seamless, resistant barrier. This lining is essential in industries such as chemical processing, pharmaceuticals, and food production, where contamination prevention and material longevity are critical.

Key Differences Between Teflon Coating and Lining

Teflon coating involves applying a thin, non-stick layer on surfaces like cookware, enhancing ease of cleaning and resistance to corrosion, while Teflon lining refers to a thicker, industrial-grade layer used inside pipes or containers to prevent chemical reactions and abrasion. Coatings are typically thinner and bonded to metal substrates for everyday use, whereas linings provide robust protection in harsh chemical environments, offering superior chemical and temperature resistance. Understanding these differences is crucial for selecting the appropriate Teflon application in cookware manufacturing versus industrial chemical processing.

Application Methods: Coating vs Lining

Teflon coating involves applying a thin, non-stick polymer layer onto surfaces through processes like spraying, brushing, or dipping, mainly used for cookware and industrial equipment. Teflon lining consists of bonding thick sheets of PTFE material to the interior surfaces of pipes, tanks, or vessels, providing enhanced chemical resistance and durability in harsh environments. Coating methods offer flexibility and easy reapplication, while lining ensures long-term protection against corrosion and abrasion.

Performance and Durability Comparison

Teflon coating offers excellent non-stick properties and resistance to corrosion, making it ideal for cookware and general surface protection, but it may wear off over time due to abrasion and high temperatures. Teflon lining, typically applied as a thick, uniform layer inside industrial equipment such as pipes and tanks, provides superior chemical resistance and enhanced durability against physical and thermal stress. The choice between Teflon coating and lining depends on the application's demand for longevity, with linings generally outperforming coatings in high-wear, industrial environments.

Cost Analysis: Coating vs Lining

Teflon coating typically offers a lower upfront cost compared to Teflon lining, making it a more budget-friendly option for surface protection in cookware and industrial applications. However, Teflon lining, often used in pipes and tanks, provides longer durability and superior chemical resistance, which can reduce maintenance expenses over time despite higher initial investment. Consideration of project scale and longevity requirements is crucial to determine the most cost-effective choice between Teflon coating and Teflon lining.

Industrial Uses for Teflon Coating

Teflon coating is widely applied in industrial machinery and equipment to provide a non-stick, corrosion-resistant surface that withstands high temperatures and chemical exposure. Unlike Teflon lining, which is used primarily for internal surfaces of pipes and vessels to prevent chemical interaction, Teflon coating enhances durability and reduces friction on external parts, such as conveyor belts and rollers. Its chemical inertness and resistance to abrasion make Teflon coating essential in industries including automotive, food processing, and pharmaceuticals.

Industrial Uses for Teflon Lining

Teflon lining is widely used in industrial applications such as chemical processing, pharmaceuticals, and food manufacturing due to its superior chemical resistance and non-reactive properties. Unlike Teflon coating, which is applied as a thin surface layer prone to wear, Teflon lining involves a thicker, more durable barrier that ensures long-term protection of equipment against corrosion and high temperatures. This durable lining extends the lifespan of pipes, tanks, and reactors, maintaining process purity and reducing maintenance costs in demanding industrial environments.

Choosing the Right Teflon Solution for Your Needs

Teflon coating provides a durable, non-stick surface ideal for cookware and machinery, offering resistance to heat and chemicals without altering the base material. Teflon lining, used primarily in industrial pipes and tanks, creates a protective barrier to prevent corrosion and contamination in aggressive chemical environments. Selecting the right Teflon solution depends on application demands, with coatings suited for surface protection and linings essential for internal chemical resistance and long-term durability.

Teflon Coating vs Teflon Lining Infographic

materialdif.com

materialdif.com