Teflon spray provides a thin, uniform coating that reduces friction and prevents rust on various surfaces, making it ideal for applications where a smooth, non-stick layer is needed. In contrast, Teflon tape serves primarily as a thread sealant for plumbing and gas connections, ensuring a tight, leak-proof fit between threaded pipes. Choosing between Teflon spray and tape depends on whether the goal is surface lubrication or sealing threaded joints.

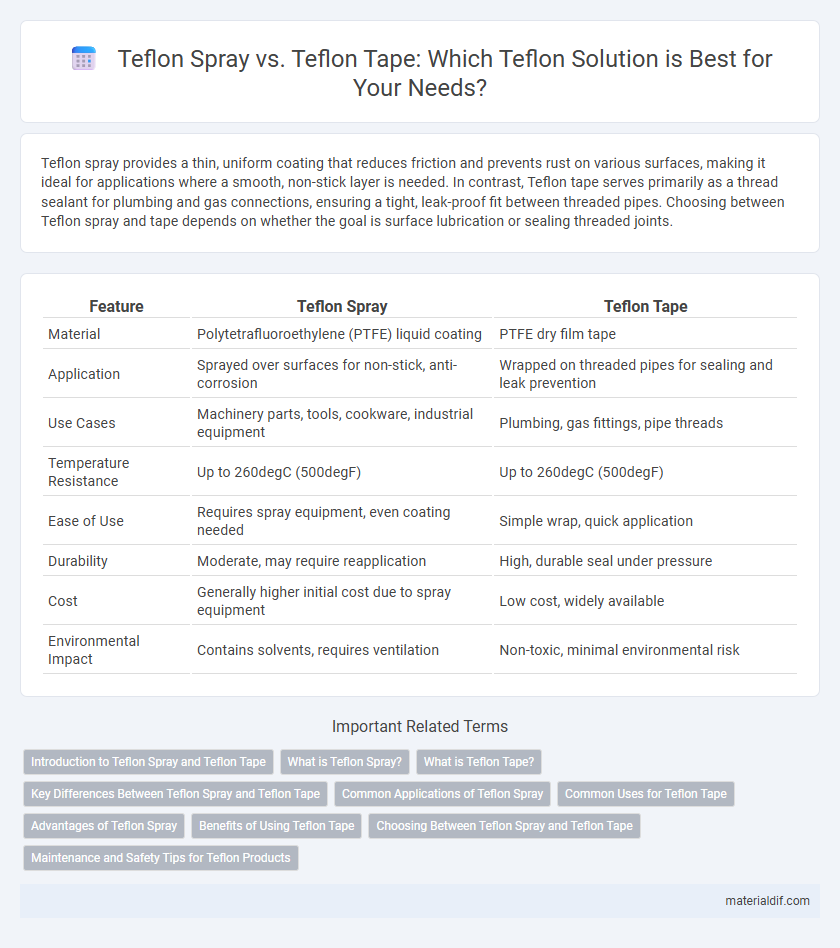

Table of Comparison

| Feature | Teflon Spray | Teflon Tape |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) liquid coating | PTFE dry film tape |

| Application | Sprayed over surfaces for non-stick, anti-corrosion | Wrapped on threaded pipes for sealing and leak prevention |

| Use Cases | Machinery parts, tools, cookware, industrial equipment | Plumbing, gas fittings, pipe threads |

| Temperature Resistance | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Ease of Use | Requires spray equipment, even coating needed | Simple wrap, quick application |

| Durability | Moderate, may require reapplication | High, durable seal under pressure |

| Cost | Generally higher initial cost due to spray equipment | Low cost, widely available |

| Environmental Impact | Contains solvents, requires ventilation | Non-toxic, minimal environmental risk |

Introduction to Teflon Spray and Teflon Tape

Teflon spray is a lubricant that creates a thin, non-stick coating ideal for reducing friction on moving parts, while Teflon tape is a sealing material used to prevent leaks in threaded pipe joints. Both products utilize polytetrafluoroethylene (PTFE) for its chemical resistance and low friction properties. Teflon spray is best suited for automotive and mechanical applications, whereas Teflon tape is commonly used in plumbing and gas fittings to ensure tight seals.

What is Teflon Spray?

Teflon spray is a liquid lubricant containing polytetrafluoroethylene (PTFE) particles that create a non-stick, low-friction coating when applied to surfaces. It is commonly used to reduce wear and corrosion on mechanical parts, tools, and equipment. Unlike Teflon tape, which acts as a thread sealant, Teflon spray provides a smooth, protective layer that enhances surface performance without adding bulk.

What is Teflon Tape?

Teflon tape, also known as PTFE (polytetrafluoroethylene) tape, is a thin, flexible white tape used primarily for sealing pipe threads and preventing leaks in plumbing applications. It provides a tight, durable seal by filling gaps between threaded metal pipes, resisting chemicals, and withstanding high temperatures. Unlike Teflon spray, which coats surfaces, Teflon tape physically wraps around threads to ensure a leak-proof connection.

Key Differences Between Teflon Spray and Teflon Tape

Teflon spray provides a thin, even coating that reduces friction and prevents corrosion on surfaces, ideal for applications requiring lubrication and protection without buildup. In contrast, Teflon tape, made from polytetrafluoroethylene (PTFE), is primarily used as a thread sealant in plumbing to create airtight, watertight seals on pipe joints. Key differences include application methods, where spray is applied as a liquid and dries into a film, while tape is physically wrapped around threads, offering durable sealing properties rather than lubrication.

Common Applications of Teflon Spray

Teflon spray is commonly used for lubricating mechanical parts, reducing friction in automotive and industrial equipment, and providing a non-stick coating on surfaces such as metal, plastic, and rubber. It is ideal for applications requiring lightweight, dry lubrication where liquid lubricants or tapes might attract dust or dirt. Teflon spray enhances the performance and longevity of moving components like hinges, gears, and conveyor belts in manufacturing and maintenance operations.

Common Uses for Teflon Tape

Teflon tape, also known as PTFE tape, is commonly used to seal pipe threads in plumbing applications, preventing leaks by filling gaps between threaded connections. It is highly effective for airtight and watertight seals in household water pipes, gas lines, and air compressors. The tape's durability and resistance to heat, chemicals, and pressure make it a preferred choice in industrial and residential pipe assembly.

Advantages of Teflon Spray

Teflon spray offers superior versatility and even coating on irregular surfaces compared to Teflon tape, making it ideal for complex machinery and tools. It provides a thin, uniform layer that reduces friction and prevents corrosion without buildup or affecting thread dimensions. The spray's ability to reach tight spaces and its effectiveness at high temperatures make it a preferred choice for industrial applications requiring reliable lubrication and protection.

Benefits of Using Teflon Tape

Teflon tape offers superior sealing capabilities in plumbing and pipe fitting applications by effectively preventing leaks and resisting corrosion. Its easy application and flexibility allow it to conform to irregular threads, ensuring a tight, durable seal under high pressure and temperature conditions. Unlike Teflon spray, tape provides long-lasting mechanical protection that enhances joint stability and reduces maintenance needs.

Choosing Between Teflon Spray and Teflon Tape

Choosing between Teflon spray and Teflon tape depends on the application requirements and surface type; Teflon spray provides an even, corrosion-resistant coating ideal for irregular or large surfaces, while Teflon tape offers a durable, moisture-resistant seal primarily used for threaded pipe joints. Teflon tape is preferred in plumbing and gas fittings for its ease of use and reliable sealing capabilities, whereas Teflon spray excels in preventing wear and reducing friction on mechanical parts. Evaluating factors like surface geometry, exposure conditions, and desired durability helps determine the optimal choice between these two Teflon products.

Maintenance and Safety Tips for Teflon Products

Teflon spray offers an easy-to-apply lubricant that reduces friction and protects surfaces without leaving residues, while Teflon tape provides a secure, chemical-resistant seal for threaded plumbing and mechanical connections. For maintenance, ensure surfaces are clean before applying Teflon spray to maximize adhesion and reapply regularly for continued protection, whereas Teflon tape should be wrapped tightly around threads in the direction of tightening to prevent leaks. Safety tips include using Teflon spray in well-ventilated areas to avoid inhaling fumes and avoiding excessive heat near Teflon tape, as high temperatures can degrade its sealing properties.

Teflon Spray vs Teflon Tape Infographic

materialdif.com

materialdif.com