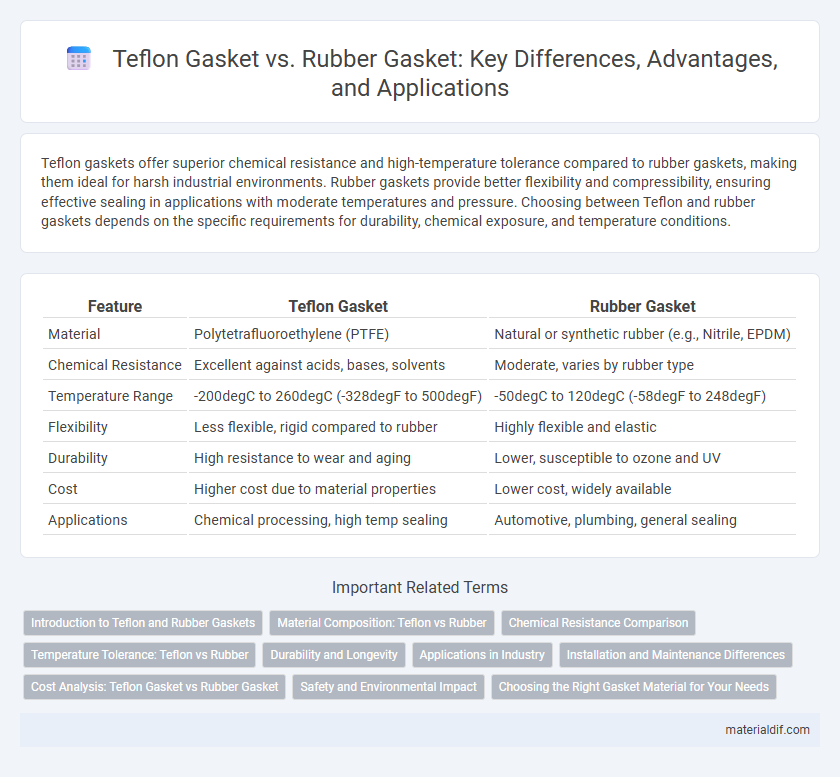

Teflon gaskets offer superior chemical resistance and high-temperature tolerance compared to rubber gaskets, making them ideal for harsh industrial environments. Rubber gaskets provide better flexibility and compressibility, ensuring effective sealing in applications with moderate temperatures and pressure. Choosing between Teflon and rubber gaskets depends on the specific requirements for durability, chemical exposure, and temperature conditions.

Table of Comparison

| Feature | Teflon Gasket | Rubber Gasket |

|---|---|---|

| Material | Polytetrafluoroethylene (PTFE) | Natural or synthetic rubber (e.g., Nitrile, EPDM) |

| Chemical Resistance | Excellent against acids, bases, solvents | Moderate, varies by rubber type |

| Temperature Range | -200degC to 260degC (-328degF to 500degF) | -50degC to 120degC (-58degF to 248degF) |

| Flexibility | Less flexible, rigid compared to rubber | Highly flexible and elastic |

| Durability | High resistance to wear and aging | Lower, susceptible to ozone and UV |

| Cost | Higher cost due to material properties | Lower cost, widely available |

| Applications | Chemical processing, high temp sealing | Automotive, plumbing, general sealing |

Introduction to Teflon and Rubber Gaskets

Teflon gaskets are made from polytetrafluoroethylene (PTFE), known for its exceptional chemical resistance, low friction, and high-temperature tolerance, making it ideal for aggressive chemical environments. Rubber gaskets, commonly composed of materials like EPDM, Nitrile, or Neoprene, offer excellent flexibility, sealing capabilities, and cost-effectiveness for general-purpose applications. Choosing between Teflon and rubber gaskets depends on factors such as chemical exposure, temperature range, and mechanical stress requirements.

Material Composition: Teflon vs Rubber

Teflon gaskets consist of polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its exceptional chemical resistance, high temperature tolerance up to 260degC, and non-reactive surface properties. Rubber gaskets, typically made from materials like nitrile, EPDM, or silicone, offer flexibility and resilience but have lower chemical resistance and temperature limits usually ranging between -40degC to 150degC. The inherent non-stick and corrosion-resistant nature of Teflon makes it ideal for aggressive chemical environments, whereas rubber gaskets provide superior elasticity for sealing dynamic joints.

Chemical Resistance Comparison

Teflon gaskets exhibit superior chemical resistance compared to rubber gaskets, effectively withstanding aggressive acids, alkalis, and solvents without degradation. While rubber gaskets such as EPDM, Nitrile, and Neoprene provide good resistance to specific chemicals, they generally lack the broad-spectrum inertness that Teflon offers. This makes Teflon the preferred choice in highly corrosive environments requiring long-term durability and minimal maintenance.

Temperature Tolerance: Teflon vs Rubber

Teflon gaskets exhibit superior temperature tolerance, functioning effectively in extreme environments ranging from -200degC to 260degC, whereas rubber gaskets typically manage temperatures between -50degC and 120degC. The chemical inertness of PTFE (Teflon) allows it to maintain integrity under high heat and aggressive chemicals, which rubber materials like EPDM or NBR cannot withstand without degradation. This makes Teflon gaskets ideal for industrial applications requiring high thermal resistance and chemical stability compared to conventional rubber gaskets.

Durability and Longevity

Teflon gaskets exhibit superior durability and longevity compared to rubber gaskets due to their exceptional resistance to chemicals, high temperatures, and environmental degradation. While rubber gaskets may degrade faster under exposure to oils, acids, and extreme temperatures, Teflon maintains structural integrity and performance over extended periods. This makes Teflon gaskets ideal for demanding industrial applications requiring long-lasting sealing solutions.

Applications in Industry

Teflon gaskets offer superior chemical resistance and high-temperature tolerance, making them ideal for aggressive chemical processing industries such as pharmaceuticals, food and beverage, and petrochemical plants. Rubber gaskets, while effective for sealing and cushioning in lower temperature and pressure applications, struggle with exposure to harsh chemicals and extreme heat, limiting their use primarily to water treatment, HVAC systems, and general machinery. The choice between Teflon and rubber gaskets hinges on the specific industrial conditions, including exposure to corrosive substances and temperature demands.

Installation and Maintenance Differences

Teflon gaskets offer superior chemical resistance and require minimal lubrication during installation, reducing the risk of damage and simplifying maintenance compared to rubber gaskets. Rubber gaskets demand careful handling to prevent tearing or deformation during installation and often require regular inspection for cracks or wear due to exposure to environmental factors. Maintenance of Teflon gaskets is generally less frequent and easier, as they maintain integrity under extreme temperatures and corrosive environments, unlike rubber gaskets which may degrade more quickly under similar conditions.

Cost Analysis: Teflon Gasket vs Rubber Gasket

Teflon gaskets generally exhibit a higher initial cost compared to rubber gaskets due to expensive raw materials and advanced manufacturing processes. Rubber gaskets, while more affordable upfront, may incur greater long-term expenses from frequent replacements in high-temperature or chemically aggressive environments. The cost-benefit analysis favors Teflon gaskets in applications demanding durability and chemical resistance, offsetting their premium price through extended service life.

Safety and Environmental Impact

Teflon gaskets offer superior chemical resistance and can withstand high temperatures, reducing the risk of leaks and enhancing safety in industrial applications compared to rubber gaskets. Unlike rubber, Teflon is inert and does not degrade into harmful substances, minimizing environmental pollution and extending the lifespan of sealing components. However, Teflon production involves perfluorinated compounds that require controlled handling to mitigate ecological impact.

Choosing the Right Gasket Material for Your Needs

Teflon gaskets offer exceptional chemical resistance and high-temperature tolerance, making them ideal for aggressive environments and applications requiring minimal degradation. Rubber gaskets provide superior flexibility and compression, suitable for sealing irregular surfaces and low to moderate temperature settings. Selecting the right gasket material depends on factors such as chemical exposure, temperature range, and mechanical stress to ensure optimal performance and durability.

Teflon Gasket vs Rubber Gasket Infographic

materialdif.com

materialdif.com