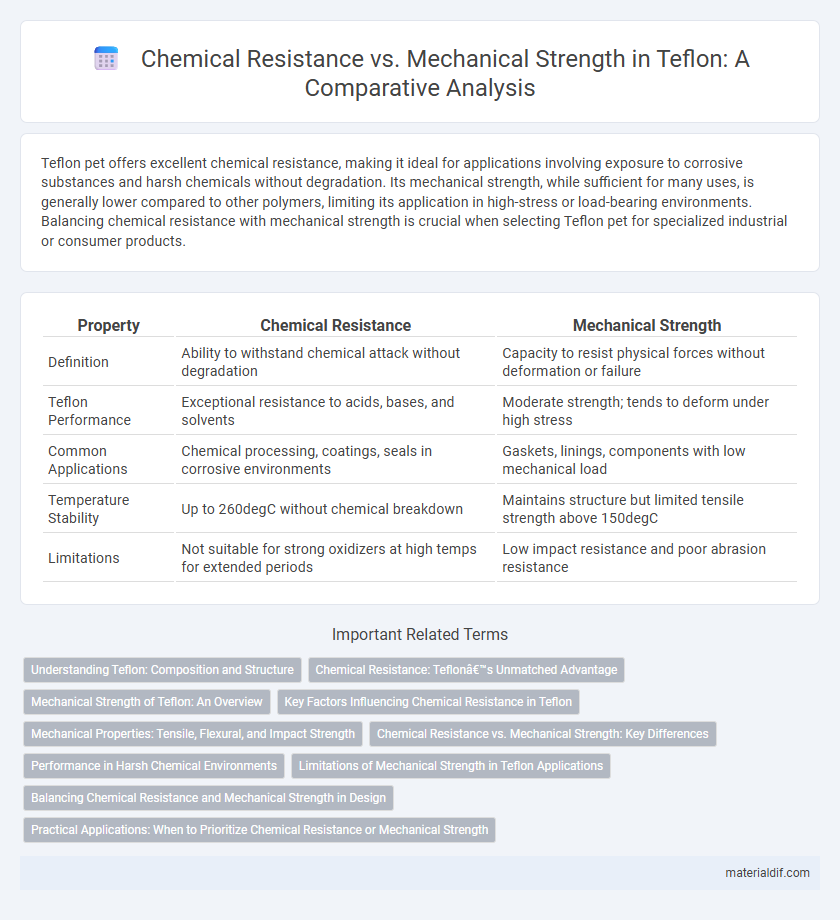

Teflon pet offers excellent chemical resistance, making it ideal for applications involving exposure to corrosive substances and harsh chemicals without degradation. Its mechanical strength, while sufficient for many uses, is generally lower compared to other polymers, limiting its application in high-stress or load-bearing environments. Balancing chemical resistance with mechanical strength is crucial when selecting Teflon pet for specialized industrial or consumer products.

Table of Comparison

| Property | Chemical Resistance | Mechanical Strength |

|---|---|---|

| Definition | Ability to withstand chemical attack without degradation | Capacity to resist physical forces without deformation or failure |

| Teflon Performance | Exceptional resistance to acids, bases, and solvents | Moderate strength; tends to deform under high stress |

| Common Applications | Chemical processing, coatings, seals in corrosive environments | Gaskets, linings, components with low mechanical load |

| Temperature Stability | Up to 260degC without chemical breakdown | Maintains structure but limited tensile strength above 150degC |

| Limitations | Not suitable for strong oxidizers at high temps for extended periods | Low impact resistance and poor abrasion resistance |

Understanding Teflon: Composition and Structure

Teflon's exceptional chemical resistance stems from its unique composition of polytetrafluoroethylene (PTFE), characterized by a carbon-fluorine bond that creates a non-reactive surface impervious to most chemicals. The molecular structure, consisting of long chains of carbon atoms each bonded to fluorine atoms, forms a strong, stable lattice that resists corrosion and chemical attack. Despite its outstanding chemical inertness, Teflon exhibits comparatively lower mechanical strength and tensile properties, requiring reinforcement or blending with other materials for applications demanding higher durability or load-bearing capacity.

Chemical Resistance: Teflon’s Unmatched Advantage

Teflon exhibits exceptional chemical resistance, making it highly resistant to corrosive chemicals, acids, and solvents, which is unmatched by most other polymer materials. Its molecular structure prevents chemical reactions and degradation, ensuring long-lasting performance in harsh environments. This superior chemical resistance is a key reason why Teflon is extensively used in industrial applications requiring inert and non-reactive surfaces.

Mechanical Strength of Teflon: An Overview

Teflon exhibits moderate mechanical strength characterized by its excellent flexibility and resistance to deformation under stress, making it suitable for applications requiring durability and resilience. Its polymer structure provides high tensile strength and abrasion resistance, although it is susceptible to creep under prolonged mechanical load. The unique combination of mechanical properties allows Teflon to maintain integrity in environments with physical wear while preserving chemical inertness.

Key Factors Influencing Chemical Resistance in Teflon

Teflon's exceptional chemical resistance is primarily influenced by its molecular structure, where strong carbon-fluorine bonds create a non-reactive surface that repels most chemicals. Factors such as polymer crystallinity, thickness of the Teflon coating, and exposure temperature significantly affect its ability to withstand aggressive solvents and corrosive environments. Mechanical strength, while important for physical durability, plays a secondary role in chemical resistance, which is predominantly controlled by intrinsic chemical inertness and environmental conditions.

Mechanical Properties: Tensile, Flexural, and Impact Strength

Teflon exhibits high chemical resistance, maintaining stability against acids, bases, and solvents, but its mechanical properties vary significantly. Its tensile strength typically ranges from 20 to 35 MPa, while flexural strength is about 25 to 30 MPa, allowing moderate resistance to deformation under stress. Despite excellent chemical inertness, Teflon has relatively low impact strength, making it prone to cracking under sudden mechanical force compared to other engineering plastics.

Chemical Resistance vs. Mechanical Strength: Key Differences

Teflon exhibits exceptional chemical resistance, making it highly effective against acids, bases, and solvents, which prevents degradation in harsh environments. Its mechanical strength, while adequate for many applications, is lower compared to metals and some engineered plastics, affecting its load-bearing capabilities. The key differences involve Teflon's superior inertness and corrosion resistance contrasting with moderate tensile strength and flexibility limitations.

Performance in Harsh Chemical Environments

Teflon exhibits exceptional chemical resistance, maintaining stability and integrity when exposed to aggressive substances such as acids, bases, and solvents. Its unique molecular structure prevents chemical reactions, ensuring durability and reliability in harsh environments. While its mechanical strength is moderate, Teflon's performance in corrosive conditions outperforms many other polymer materials, making it ideal for sealing, lining, and coating applications where chemical exposure is a critical factor.

Limitations of Mechanical Strength in Teflon Applications

Teflon exhibits exceptional chemical resistance, making it ideal for harsh environments involving strong acids and bases. However, its mechanical strength is comparatively low, with poor tensile strength and limited resistance to abrasion or impact. This limitation restricts Teflon's use in load-bearing or high-stress applications where structural integrity is critical.

Balancing Chemical Resistance and Mechanical Strength in Design

Balancing chemical resistance and mechanical strength in Teflon design requires optimizing polymer morphology and filler additives to enhance durability without compromising corrosion resistance. Incorporating glass fibers or carbon nanotubes can significantly improve tensile strength and impact resistance while maintaining Teflon's inherent chemical inertness against acids, bases, and solvents. Engineering the composite properties allows Teflon applications to withstand harsh environments and mechanical stresses in industries such as chemical processing and aerospace.

Practical Applications: When to Prioritize Chemical Resistance or Mechanical Strength

In industrial applications involving Teflon, prioritize chemical resistance when exposure to aggressive solvents, acids, or bases is frequent, such as in chemical processing equipment and laboratory containers. Mechanical strength becomes critical in applications requiring wear resistance, impact durability, or load-bearing components, including seals, gaskets, and bearings subjected to physical stress. Balancing chemical resistance and mechanical strength ensures optimal performance and longevity tailored to specific operational demands.

Chemical Resistance vs Mechanical Strength Infographic

materialdif.com

materialdif.com