Teflon AF exhibits exceptional optical clarity and low dielectric constant, making it ideal for high-performance optical and electronic applications. Tefzel offers superior mechanical strength and chemical resistance, with enhanced flexibility suited for harsh environments and protective coatings. Choosing between Teflon AF and Tefzel depends on the required balance between optical properties and mechanical durability in specialized industrial uses.

Table of Comparison

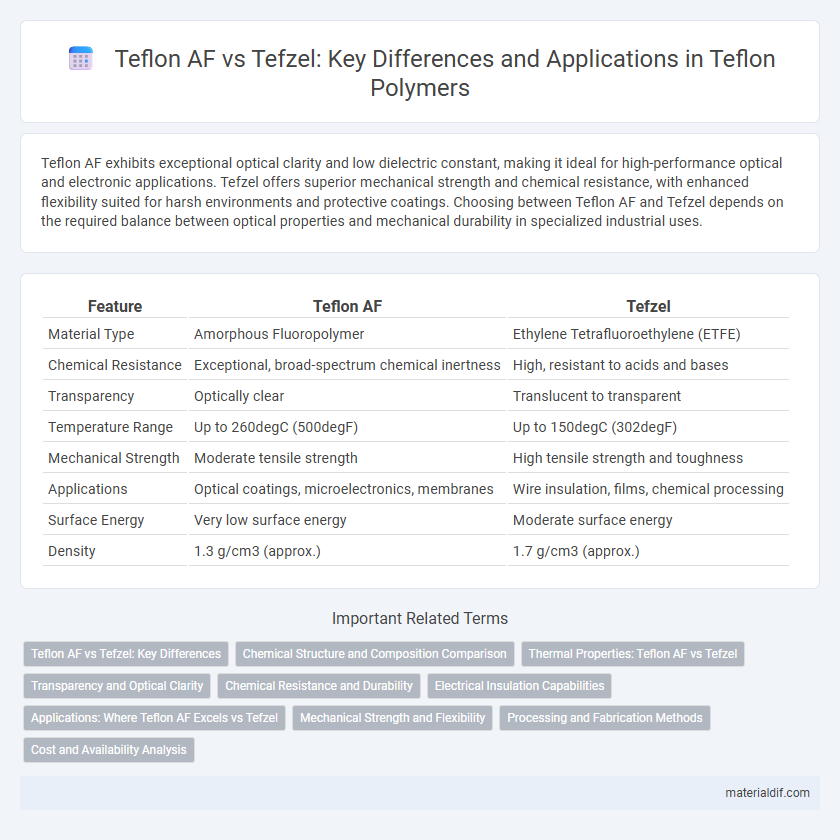

| Feature | Teflon AF | Tefzel |

|---|---|---|

| Material Type | Amorphous Fluoropolymer | Ethylene Tetrafluoroethylene (ETFE) |

| Chemical Resistance | Exceptional, broad-spectrum chemical inertness | High, resistant to acids and bases |

| Transparency | Optically clear | Translucent to transparent |

| Temperature Range | Up to 260degC (500degF) | Up to 150degC (302degF) |

| Mechanical Strength | Moderate tensile strength | High tensile strength and toughness |

| Applications | Optical coatings, microelectronics, membranes | Wire insulation, films, chemical processing |

| Surface Energy | Very low surface energy | Moderate surface energy |

| Density | 1.3 g/cm3 (approx.) | 1.7 g/cm3 (approx.) |

Teflon AF vs Tefzel: Key Differences

Teflon AF and Tefzel are both fluoropolymer materials but differ significantly in properties and applications. Teflon AF is an amorphous fluoropolymer known for its exceptional optical clarity, very low refractive index, and outstanding chemical resistance, making it ideal for optical coatings and membranes. In contrast, Tefzel is a type of ETFE copolymer characterized by high mechanical strength, excellent UV resistance, and flexibility, commonly used in architectural films and electrical insulation.

Chemical Structure and Composition Comparison

Teflon AF is a copolymer of tetrafluoroethylene (TFE) and 2,2-bis(trifluoromethyl)-4,5-difluoro-1,3-dioxole, characterized by its amorphous structure that provides high optical clarity and excellent gas barrier properties. Tefzel, on the other hand, is a copolymer of ethylene and tetrafluoroethylene (ETFE), featuring a semi-crystalline structure that offers enhanced mechanical strength and chemical resistance. The primary difference in chemical composition influences Teflon AF's superior transparency and permeability control, while Tefzel's crystalline regions contribute to toughness and durability in harsh environments.

Thermal Properties: Teflon AF vs Tefzel

Teflon AF exhibits superior thermal stability with a continuous service temperature up to 260degC, maintaining performance in extreme heat, whereas Tefzel operates effectively up to 150degC. The glass transition temperature of Teflon AF is around 240degC, contributing to its excellent thermal resistance, compared to Tefzel's Tg at approximately 85degC. These thermal properties make Teflon AF ideal for high-temperature applications requiring chemical inertness and low gas permeability, while Tefzel suits moderately high-heat environments with its toughness and flexibility.

Transparency and Optical Clarity

Teflon AF offers superior optical clarity and transparency compared to Tefzel, making it ideal for applications requiring high light transmission and minimal haze. Teflon AF exhibits a high refractive index with excellent UV-visible light transmittance, whereas Tefzel, a copolymer of ethylene and tetrafluoroethylene, shows lower transparency due to its semi-crystalline nature. The enhanced transparency of Teflon AF makes it preferable for advanced optical components and precise light-guiding applications.

Chemical Resistance and Durability

Teflon AF exhibits superior chemical resistance due to its amorphous fluoropolymer structure, effectively resisting strong acids, bases, and solvents, while maintaining excellent thermal stability up to 260degC. Tefzel, a copolymer of ethylene and tetrafluoroethylene, offers robust durability with enhanced mechanical strength and flexibility, making it ideal for applications requiring impact resistance and weatherability. Both materials excel in chemical resistance, but Teflon AF is preferred for high-performance environments demanding exceptional inertness and thermal endurance.

Electrical Insulation Capabilities

Teflon AF exhibits superior electrical insulation capabilities due to its amorphous fluoropolymer structure, resulting in lower dielectric constant and higher volume resistivity compared to Tefzel. Tefzel, a copolymer of ethylene and tetrafluoroethylene, provides good dielectric strength but typically has higher electrical losses and lower breakdown voltage than Teflon AF. These properties make Teflon AF preferable for advanced microelectronics and high-frequency insulation applications demanding exceptional dielectric performance.

Applications: Where Teflon AF Excels vs Tefzel

Teflon AF is highly suited for advanced optical and electronic applications due to its exceptional transparency and low refractive index, making it ideal for fiber optics and flexible electronics. In contrast, Tefzel excels in industrial and chemical processing uses thanks to its superior chemical resistance and mechanical toughness. Teflon AF's outstanding gas barrier properties dominate in high-performance membrane and coating applications, whereas Tefzel offers durability in harsh environments such as cable jacketing and molded components.

Mechanical Strength and Flexibility

Teflon AF offers superior flexibility due to its amorphous structure, making it ideal for applications requiring dynamic movement and bending without cracking. Tefzel, a copolymer of ethylene and tetrafluoroethylene, exhibits higher mechanical strength and impact resistance, suitable for environments with significant mechanical stress. While Teflon AF excels in flexibility and chemical resistance, Tefzel provides a balanced combination of toughness and durability.

Processing and Fabrication Methods

Teflon AF, an amorphous fluoropolymer, is processed primarily through solvent-based methods like spin coating and dip coating due to its solubility in fluorinated solvents, enabling the formation of thin, uniform films. Tefzel, a copolymer of ethylene and tetrafluoroethylene, is typically fabricated via melt processing techniques such as extrusion and injection molding, benefiting from its higher thermal stability and toughness. The distinct processing methods reflect their material structures, with Teflon AF favored for precision coatings in microelectronics and Tefzel preferred for robust, molded components in chemical and electrical applications.

Cost and Availability Analysis

Teflon AF is a high-performance amorphous fluoropolymer with limited availability and higher production costs due to its specialized synthesis process. Tefzel, a copolymer of ethylene and tetrafluoroethylene, is more widely available and cost-effective, benefiting from established manufacturing infrastructure and bulk production. The cost differential between Teflon AF and Tefzel significantly influences material selection in applications requiring specific chemical resistance and mechanical properties.

Teflon AF vs Tefzel Infographic

materialdif.com

materialdif.com