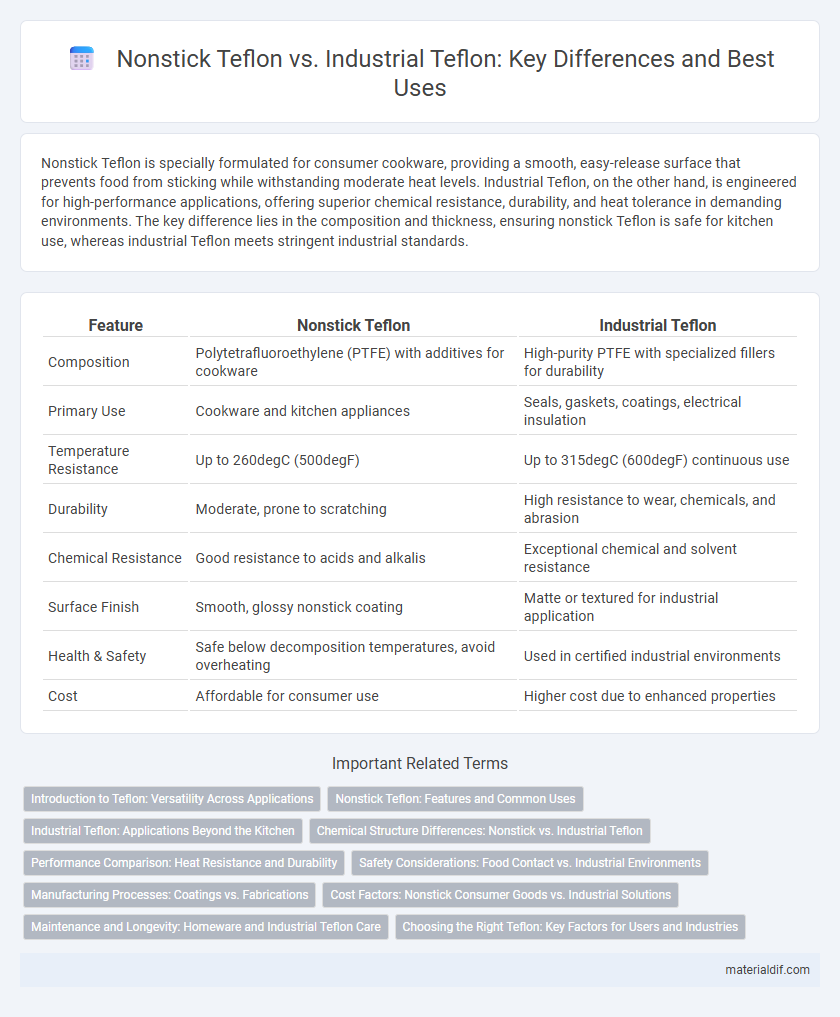

Nonstick Teflon is specially formulated for consumer cookware, providing a smooth, easy-release surface that prevents food from sticking while withstanding moderate heat levels. Industrial Teflon, on the other hand, is engineered for high-performance applications, offering superior chemical resistance, durability, and heat tolerance in demanding environments. The key difference lies in the composition and thickness, ensuring nonstick Teflon is safe for kitchen use, whereas industrial Teflon meets stringent industrial standards.

Table of Comparison

| Feature | Nonstick Teflon | Industrial Teflon |

|---|---|---|

| Composition | Polytetrafluoroethylene (PTFE) with additives for cookware | High-purity PTFE with specialized fillers for durability |

| Primary Use | Cookware and kitchen appliances | Seals, gaskets, coatings, electrical insulation |

| Temperature Resistance | Up to 260degC (500degF) | Up to 315degC (600degF) continuous use |

| Durability | Moderate, prone to scratching | High resistance to wear, chemicals, and abrasion |

| Chemical Resistance | Good resistance to acids and alkalis | Exceptional chemical and solvent resistance |

| Surface Finish | Smooth, glossy nonstick coating | Matte or textured for industrial application |

| Health & Safety | Safe below decomposition temperatures, avoid overheating | Used in certified industrial environments |

| Cost | Affordable for consumer use | Higher cost due to enhanced properties |

Introduction to Teflon: Versatility Across Applications

Teflon, a brand name for polytetrafluoroethylene (PTFE), exhibits remarkable versatility in both nonstick cookware and industrial applications due to its exceptional chemical resistance, low friction, and high-temperature tolerance. Nonstick Teflon coatings are formulated to provide smooth, food-safe surfaces that prevent sticking and facilitate easy cleaning, while industrial Teflon variants are engineered for durability in harsh environments including chemical processing, aerospace, and electrical insulation. These diverse formulations demonstrate Teflon's adaptability, making it indispensable across consumer goods and advanced industrial sectors.

Nonstick Teflon: Features and Common Uses

Nonstick Teflon, primarily composed of polytetrafluoroethylene (PTFE), features exceptional nonstick properties and high resistance to heat up to 260degC (500degF), making it ideal for cookware and bakeware applications. Its low friction surface prevents food adhesion, promoting easy cleaning and healthy cooking by minimizing oil use. Common uses extend to kitchen utensils, frying pans, and bake trays, as well as coatings for small appliances and food-processing equipment where non-reactivity and durability are essential.

Industrial Teflon: Applications Beyond the Kitchen

Industrial Teflon, made from polytetrafluoroethylene (PTFE), is widely used in chemical processing, aerospace, and electronics due to its exceptional chemical resistance, high temperature tolerance, and low friction properties. Unlike nonstick Teflon coatings designed for cookware, Industrial Teflon serves crucial roles in sealing, gaskets, insulation, and linings for pipes and tanks handling corrosive substances. Its unique ability to withstand extreme environments makes Industrial Teflon indispensable in heavy machinery, semiconductor manufacturing, and even medical devices.

Chemical Structure Differences: Nonstick vs. Industrial Teflon

Nonstick Teflon, primarily polytetrafluoroethylene (PTFE), features a highly branched, linear polymer structure with a high molecular weight that creates its characteristic low surface energy and nonstick properties. Industrial Teflon variants often incorporate copolymers or additives like perfluoroalkoxy alkane (PFA) or fluorinated ethylene propylene (FEP), enhancing thermal stability, chemical resistance, and mechanical strength for demanding industrial applications. These structural modifications result in differences in crystallinity, melting points, and chemical inertness between nonstick and industrial Teflon formulations.

Performance Comparison: Heat Resistance and Durability

Nonstick Teflon coatings typically withstand temperatures up to 260degC (500degF), making them ideal for everyday cookware, while Industrial Teflon can endure continuous exposure to temperatures nearing 290degC (554degF) with enhanced chemical resistance. Durability-wise, Industrial Teflon formulations feature reinforced polymers and fillers, offering superior abrasion resistance and lifespan compared to the thinner, more flexible nonstick varieties. This performance disparity ensures Industrial Teflon's suitability for heavy-duty applications such as chemical processing equipment, whereas nonstick Teflon prioritizes ease of cleaning and food release in kitchen environments.

Safety Considerations: Food Contact vs. Industrial Environments

Nonstick Teflon coatings used in cookware are formulated to ensure food safety by adhering to strict FDA regulations that limit harmful chemical emissions at cooking temperatures below 500degF (260degC). Industrial Teflon applications, such as gaskets and seals, often involve higher thermal or chemical stress where PTFE's chemical inertness and thermal stability protect equipment, but these uses do not require food-grade certification. Understanding the differences in formulation and regulatory standards is essential for safe application of Teflon in food contact versus industrial environments.

Manufacturing Processes: Coatings vs. Fabrications

Nonstick Teflon coatings are applied through a spray or dip process that bonds a thin layer of polytetrafluoroethylene (PTFE) to cookware surfaces, ensuring a smooth, low-friction finish ideal for food release. Industrial Teflon fabrications involve molding or machining bulk PTFE materials into components such as seals, gaskets, or liners, leveraging its chemical resistance and high-temperature tolerance. The manufacturing process for nonstick coatings prioritizes surface adhesion and uniformity, whereas industrial fabrications focus on material density and structural integrity.

Cost Factors: Nonstick Consumer Goods vs. Industrial Solutions

Nonstick Teflon used in consumer goods typically incurs lower production costs due to simpler formulations and mass manufacturing processes, making it affordable for everyday kitchenware. Industrial Teflon applications demand higher purity, tailored chemical properties, and enhanced durability, significantly increasing material and processing expenses. Cost factors for industrial Teflon also include stringent quality controls and customization that do not apply to standard nonstick coatings.

Maintenance and Longevity: Homeware and Industrial Teflon Care

Nonstick Teflon cookware requires gentle cleaning with non-abrasive sponges to preserve its delicate coating, ensuring prolonged nonstick performance and preventing surface scratches. Industrial Teflon, used in applications like chemical processing or machinery parts, demands routine inspections and specialized cleaning agents to maintain its chemical resistance and structural integrity under harsh operating conditions. Proper maintenance of both types extends their functional lifespan, with nonstick homeware focusing on avoiding overheating and industrial Teflon emphasizing durability against mechanical wear and corrosive environments.

Choosing the Right Teflon: Key Factors for Users and Industries

Nonstick Teflon features a smooth, low-friction coating commonly used in cookware to prevent food adhesion, while Industrial Teflon offers enhanced chemical resistance and durability for applications in machinery and chemical processing. Key factors for choosing the right Teflon include temperature tolerance, chemical exposure, mechanical stress requirements, and surface finish specifications. Users must evaluate these parameters alongside cost considerations to ensure optimal performance and longevity in their specific application.

Nonstick Teflon vs Industrial Teflon Infographic

materialdif.com

materialdif.com