Powder metallurgy steel offers superior uniformity in microstructure and enhanced mechanical properties compared to traditional steel, achieved through controlled particle consolidation and sintering processes. This method reduces material wastage and allows for the production of complex shapes with tight tolerances, which traditional steel manufacturing struggles to achieve efficiently. Though initial costs may be higher, powder metallurgy steel provides improved wear resistance and fatigue strength, making it ideal for high-performance and precision applications.

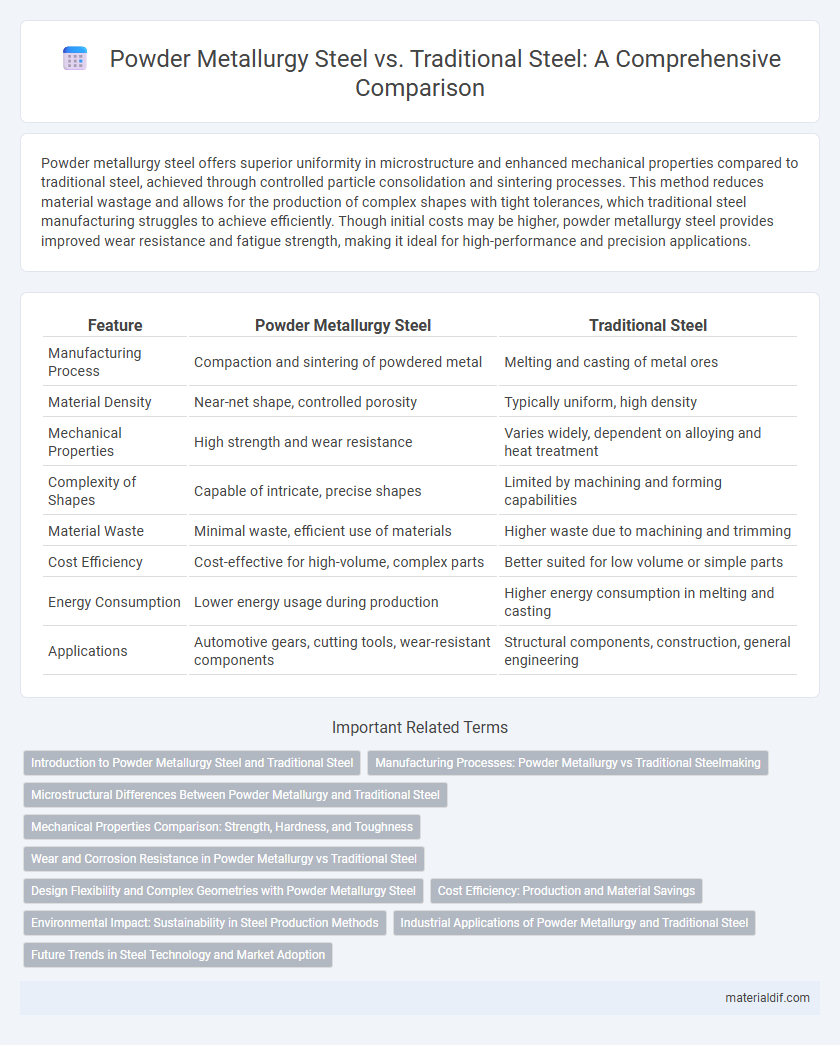

Table of Comparison

| Feature | Powder Metallurgy Steel | Traditional Steel |

|---|---|---|

| Manufacturing Process | Compaction and sintering of powdered metal | Melting and casting of metal ores |

| Material Density | Near-net shape, controlled porosity | Typically uniform, high density |

| Mechanical Properties | High strength and wear resistance | Varies widely, dependent on alloying and heat treatment |

| Complexity of Shapes | Capable of intricate, precise shapes | Limited by machining and forming capabilities |

| Material Waste | Minimal waste, efficient use of materials | Higher waste due to machining and trimming |

| Cost Efficiency | Cost-effective for high-volume, complex parts | Better suited for low volume or simple parts |

| Energy Consumption | Lower energy usage during production | Higher energy consumption in melting and casting |

| Applications | Automotive gears, cutting tools, wear-resistant components | Structural components, construction, general engineering |

Introduction to Powder Metallurgy Steel and Traditional Steel

Powder metallurgy steel is produced by compacting fine metal powders under high pressure and sintering them at elevated temperatures, resulting in precise control over composition and microstructure. Traditional steel is typically manufactured through melting and casting processes followed by hot or cold working, which can lead to more variable grain structures and properties. The powder metallurgy approach offers enhanced material uniformity, reduced waste, and the ability to produce complex shapes with superior mechanical properties compared to conventional steel-making methods.

Manufacturing Processes: Powder Metallurgy vs Traditional Steelmaking

Powder metallurgy steel is produced by compressing metal powders in a mold and then sintering them at high temperatures, resulting in precise control over composition and microstructure with minimal material waste. Traditional steelmaking involves melting raw materials in a blast furnace or electric arc furnace followed by casting and forging, which often leads to higher energy consumption and material loss during shaping and machining. The powder metallurgy process offers superior uniformity and allows for complex shapes without extensive machining, making it advantageous for specialized applications.

Microstructural Differences Between Powder Metallurgy and Traditional Steel

Powder metallurgy steel features a finer, more uniform microstructure compared to traditional steel, resulting from the controlled cooling process during powder consolidation. This microstructural uniformity enhances mechanical properties such as toughness, wear resistance, and fatigue strength by minimizing defects like segregation and coarse grain boundaries found in traditional steel. The presence of evenly distributed porosity and smaller grain size in powder metallurgy steel significantly improves performance in demanding engineering applications.

Mechanical Properties Comparison: Strength, Hardness, and Toughness

Powder metallurgy steel exhibits higher tensile strength and uniform hardness due to its fine microstructure and controlled alloy composition, outperforming traditional steel in wear resistance. Traditional steel often offers superior toughness and ductility, attributed to its coarser grain structure and conventional manufacturing processes. Balancing hardness and toughness depends on the specific application, with powder metallurgy steel excelling in precision components requiring high strength and consistent hardness.

Wear and Corrosion Resistance in Powder Metallurgy vs Traditional Steel

Powder metallurgy steel exhibits superior wear and corrosion resistance compared to traditional steel due to its uniform microstructure and fine grain size achieved through controlled powder processing. The enhanced homogeneity minimizes weak points and porosity, reducing corrosion sites and improving surface durability under abrasive conditions. This makes powder metallurgy steel ideal for applications demanding high performance in hostile environments where traditional steel may fail more rapidly.

Design Flexibility and Complex Geometries with Powder Metallurgy Steel

Powder metallurgy steel enables greater design flexibility by allowing the production of complex geometries that are difficult to achieve with traditional steel processing methods. The powder compaction and sintering process permits intricate shapes and fine details without extensive machining or material wastage. This advantage makes powder metallurgy steel ideal for applications requiring precision components with complex internal structures and tight tolerances.

Cost Efficiency: Production and Material Savings

Powder metallurgy steel offers significant cost efficiency over traditional steel by reducing material waste through near-net-shape manufacturing and minimizing secondary machining. Production processes in powder metallurgy enable precise alloy composition control, leading to less expensive raw material use and consistent quality. These factors combined result in lower overall manufacturing costs and improved economic sustainability for high-volume steel components.

Environmental Impact: Sustainability in Steel Production Methods

Powder metallurgy steel significantly reduces raw material waste and energy consumption compared to traditional steel production, contributing to lower greenhouse gas emissions. This method enables precise alloying and near-net-shape manufacturing, which minimizes machining requirements and scrap generation. Consequently, powder metallurgy supports more sustainable steel production by enhancing resource efficiency and reducing environmental footprint.

Industrial Applications of Powder Metallurgy and Traditional Steel

Powder metallurgy steel offers enhanced wear resistance and complex shapes ideal for aerospace and automotive components, reducing material waste and machining costs. Traditional steel remains dominant in construction and heavy machinery due to its superior toughness and ease of large-scale production. Industrial applications leverage powder metallurgy for precision parts like gears and bearings, while traditional steel suits structural beams and pipelines where mass production and strength are critical.

Future Trends in Steel Technology and Market Adoption

Powder metallurgy steel offers enhanced microstructural control and superior mechanical properties compared to traditional steel, enabling industry-wide shifts toward lightweight and high-performance materials. Future trends emphasize additive manufacturing integration with powder metallurgy to optimize production efficiency and material sustainability. Market adoption is accelerating as advanced alloys meet aerospace, automotive, and energy sector demands for improved durability and reduced environmental impact.

Powder Metallurgy Steel vs Traditional Steel Infographic

materialdif.com

materialdif.com